Finding the right technology for surface roughness measurement

Surface roughness is a broad field and can be measured in different ways - mainly with tactile stylus or non-contact optical methods.

The right choice depends on whether profile-based parameters are sufficient, whether the surface can be contacted, and whether areal 3D information is required for function, appearance, or process control.

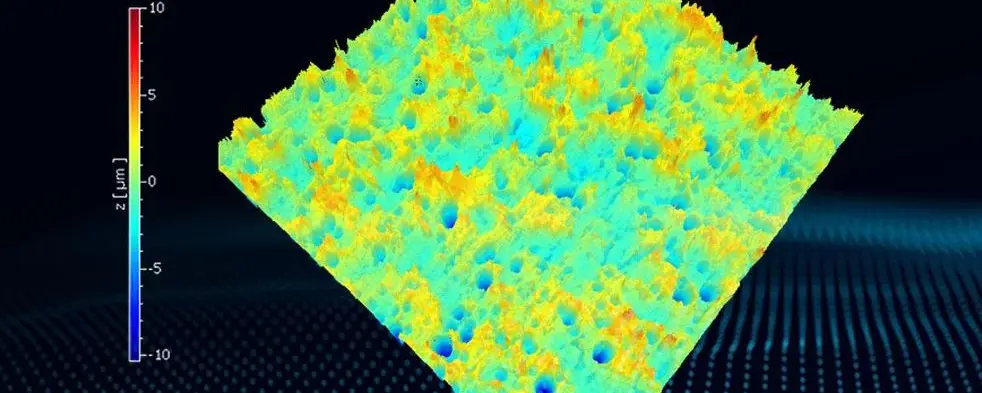

Areal roughness parameters even for challenging surfaces

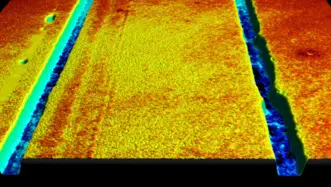

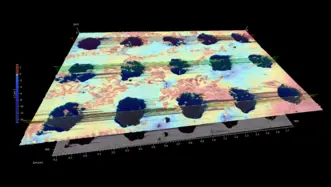

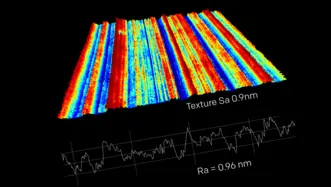

Because of the various advantages, Polytec’s surface profilers use modern white‑light interferometry to maximize usable data across materials and feature scales. Especially with very dark or highly reflective / fine polished surfaces, our customers struggled with our technologies. Therefore, we recommend to use WLI for surface roughness measurement due to the non-contact, surface independent and highly precise areal analysis.

Besides the measurement technology, the optical setup should be considered. At Polytec we have developed two different setups for roughness measurement:

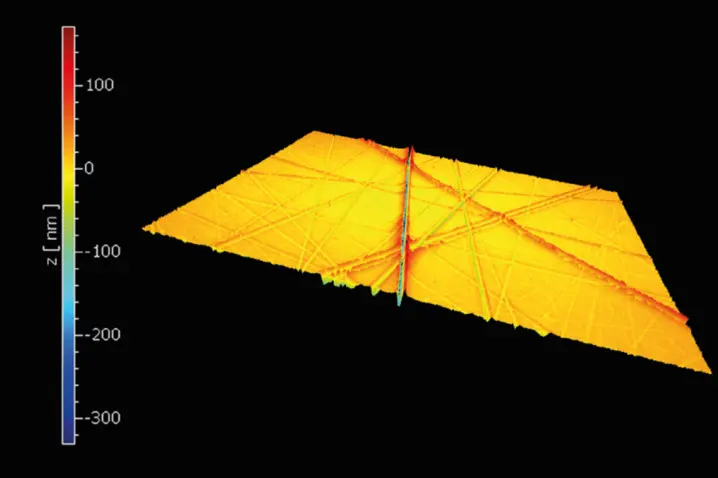

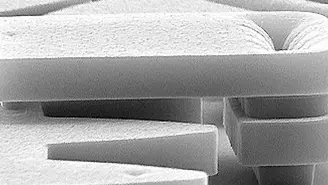

- Micro.View® line — the microscopic system for small areas and micro‑features when lateral resolution and visual details are paramount. The optics can focus on a narrow spot and thus go into every detail down to nanometers.

- Pro.Surf+ — is a macroscopic workstation with a telecentric setup. The beams/rays run in parallel covering a much broader area and enable by this measurement next to step flanks and even in bores.

Different metrology tasks may need different profiler technologies

The table below shows some specific measurement jobs and a recommendation for the best fitting system.

Task context | What the task demands | Best fit | Why this is a fit |

| Micro‑textured coatings, MEMS, vias, bond pads | High lateral resolution; spot analysis / micro areas; rich 3D documentation | Micro.View | Objectives matched to region of interest (ROI) deliver detail‑rich areal roughness; ideal for R&D and failure analysis of very narrow regions of interest |

| Optical components, fine polishing marks, micro‑scratches | Detect subtle texture; correlate topography with appearance | Micro.View | Microscopic areal data with high‑quality visuals for clear defect evidence |

| Precision‑machined metal faces (ground, honed, lapped) | Large FoV; long Z; repeatable SPC/GR&R; form + roughness in one | Pro.Surf+ | Multi‑sensor WLI with telecentric optics and recipe control for QC |

| Deep/recessed or hard‑to‑reach surfaces | Telecentric access; stable fixtures; combined evaluation | Pro.Surf+ | Large working distance and telecentric lensing maintain accuracy in recessed features |

| Multiple parts per cycle, at‑line checks | Throughput; operator‑independent pass/fail; data export | Pro.Surf+ | Recipe‑based routines with SPC integration and fixturing for trays |

Our surface roughness profiler - from micro to macro

Micro.View

TopMap Micro.View® is an easy to use optical profiler in a compact table-top setup. Choose Micro.View® as the cost-effective inspection tool for examining precision-engineered surfaces down to the sub-nm range, for inspecting roughness, microstructures and more surface details.

Micro.View+

Advanced microscope-based surface profiler with automation and color imaging. Micro.View+ enables repeatable, operator-independent roughness and texture analysis—ready for lab and production use.

Pro.Surf+

Multi-sensor optical profiler combining large-area form measurement with integrated roughness analysis. Pro.Surf+ delivers fast, traceable form and roughness results in one production-ready system.

Choose the right surface profiler with confidence—benefit from our "try before buy" approach.

Related measurement tasks

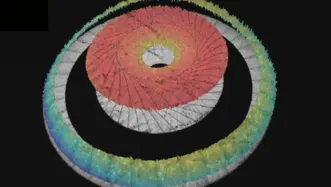

Maintain form and position tolerances

Verify form and position tolerances such as waviness, flatness, parallelism and tilt. Optical 3D surface metrology delivers reliable results—even in bores.

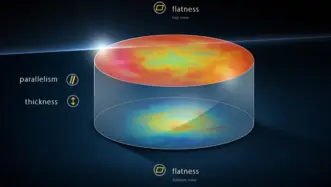

Flatness, thickness and parallelism

Flatness, thickness and parallelism (FTP) measurement combines top & bottom topography measurement in a single shot.

Coatings and layer thickness

Coating quality control in 3D. Assessing pre-coat texture, post-coat defects, and film thickness.

Tribology analysis

Tribology analysis with 3D surface profiler. Inspecting friction, wear and lubrication performance.

Pass/fail analysis

WLIs deliver fast, objective and easy-to-use pass/fail feedback from areal 3D data. Sub-nanometer Z and recipe-driven workflows support inline SPC.

Surface metrology on microstructures

Topography & dynamics of microstructures and for nanotech. 3D geometry, roughness, and time-resolved motion.

Related articles and downloads

ISO 21920 roughness

ISO 21920 is the new standard for mechanical engineering, design and roughness specifications

Form deviation & roughness

Characterize entire workpiece surfaces, calculate volume and exactly determine peaks and valleys on behalf of the examined distance parameters.

Surface roughness

Measurement of surface roughness, evaluation of profile & surface roughness.

Downloads

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.