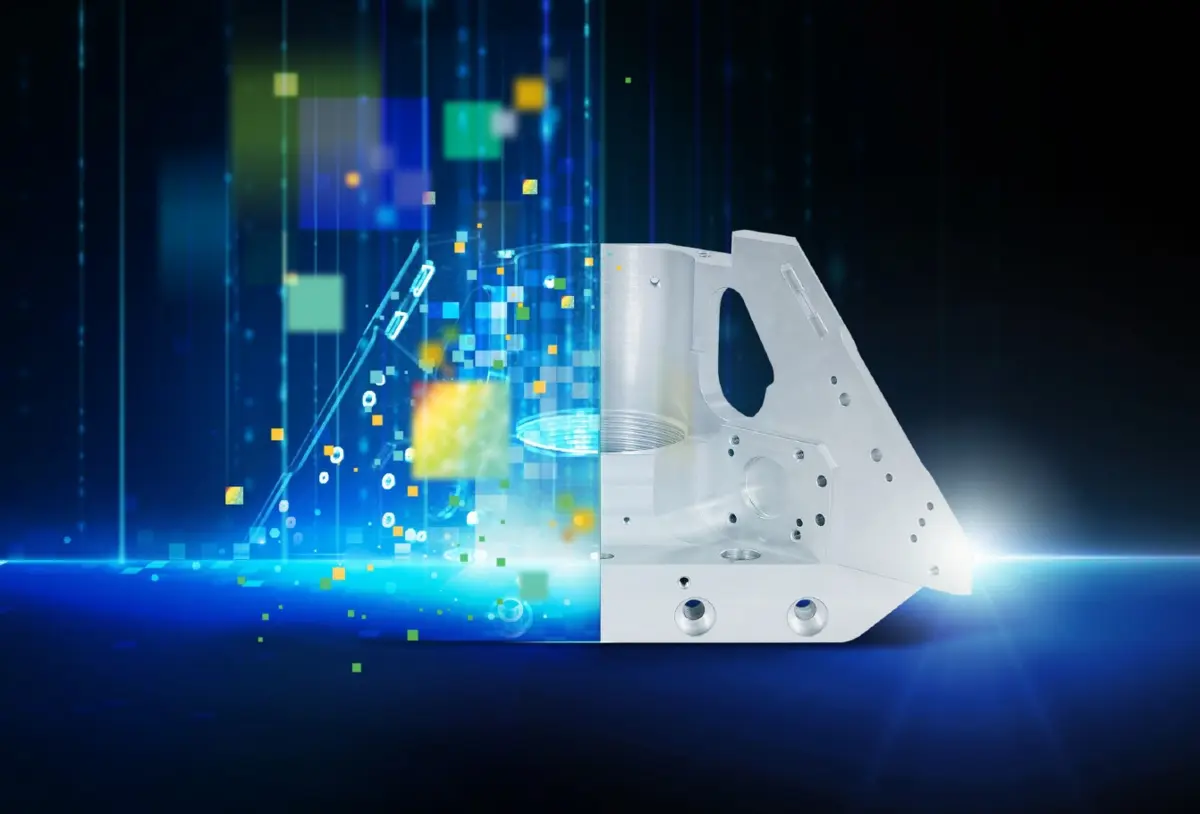

Vibration measurement tasks

Measure remotely on red-hot surfaces, on rotating components, analyze high-frequency ultrasonic tools and fully understand the dynamic behaviour of the most complex and delicate structures in 3D. See how Polytec's vibration measurement technology helps to reveal the true vibration, acoustics and dynamics of vibrating structures.

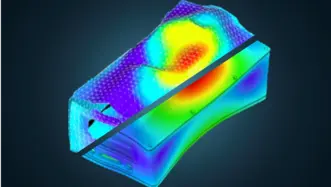

FE model validation

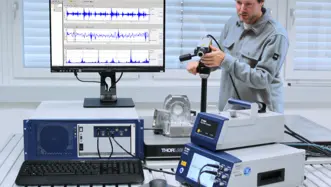

How to validate Finite Element models effectively using reliable optical measurement data with FE model like spatial resolution? Finite Element (FE) models can greatly reduce development time and cost. The idea behind FEM validation is to compare simulation results to real test data, the so-called experimental modal test. Polytec Scanning Vibrometers measure and provide 2D/3D deflection shapes as an intuitive visualization.

Modal analysis

Modal analysis is the process of finding the inherent natural vibration properties of a structure. Vibration modes of a structure can be either simulated, e.g. from Finite Element (FE) Models or can be derived from physical measurement results by fitting a mathematical model to these results. This latter process is called experimental modal analysis.

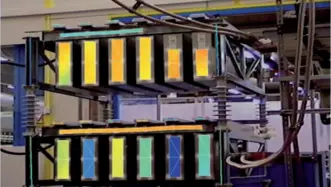

Reliability testing

Reliability of electronic components is critical for traffic safety and competitiveness in automotive and aviation industries. Scanning laser vibrometry is an essential method for mechanical testing, enabling precise characterization of dynamic behavior in printed circuit boards (PCBs) and mechatronic systems.

Amplitude measurement

Laser vibration measurement technology measures amplitudes independently of frequency, quickly and reliably. Scanning vibrometry, in particular, allows area-based and non-contact amplitude measurement and is commonly used in research and product development for FE model validation, prototype testing or design optimization.

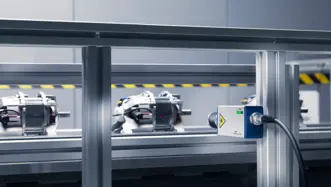

End-of-line vibration testing

End-of-line (EoL) vibration testing for quality control of manufactured products - non-contact vibro-acoustic testing in line, at line or as 100% EoL testing. Laser Doppler vibration sensors offer reliable and precise measurements for clear pass-fail decisions.

Resonance testing

Resonance testing is a valuable technique used in various industries to assess the structural integrity and quality of mechanical components or systems by analyzing their natural vibration frequencies and modes. It involves exciting the component with a mechanical or acoustic force or input and then measuring the response of the component to determine its resonance characteristics.

Fatigue testing

Reliable material parameters are essential if simulation models are to make safe predictions – especially when durability of the service life is being calculated. Structures in automotive engineering, medicine and energy technology are exposed to load changes of more than ten million cycles over the course of their expected lifetime –due to either high-frequency stress or a long operating time of up to 30 years.

Material testing

Material properties are determined with zero contact using laser vibrometers. Conclusions can be drawn as to a material sample’s strength by determining the resonance frequency during broadband excitation. This method is used to ensure quality when manufacturing different building materials, since it is completely non-destructive.

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.