Dive into specific measurement tasks for surface inspection

Functional and process requirements are expressed through standardized surface parameters that quantify topography and texture. The following collection details each parameter, recommended practices for evaluation, and compatible measurement systems.

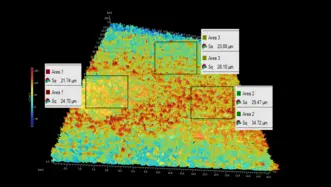

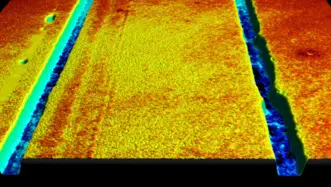

Surface roughness measurement

Surface texture analysis in 3D. From Sa/Sq to Str/Sal for validating specifications and surface features.

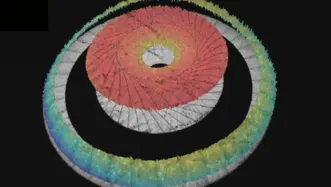

Maintain form and position tolerances

Verify form and position tolerances such as waviness, flatness, parallelism and tilt. Optical 3D surface metrology delivers reliable results—even in bores.

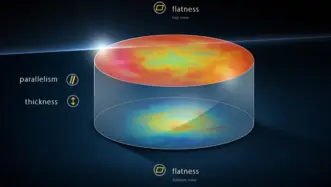

Flatness, thickness and parallelism

Flatness, thickness and parallelism (FTP) measurement combines top & bottom topography measurement in a single shot.

Coatings and layer thickness

Coating quality control in 3D. Assessing pre-coat texture, post-coat defects, and film thickness.

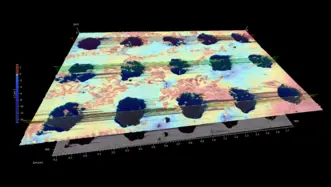

Tribology analysis

Tribology analysis with 3D surface profiler. Inspecting friction, wear and lubrication performance.

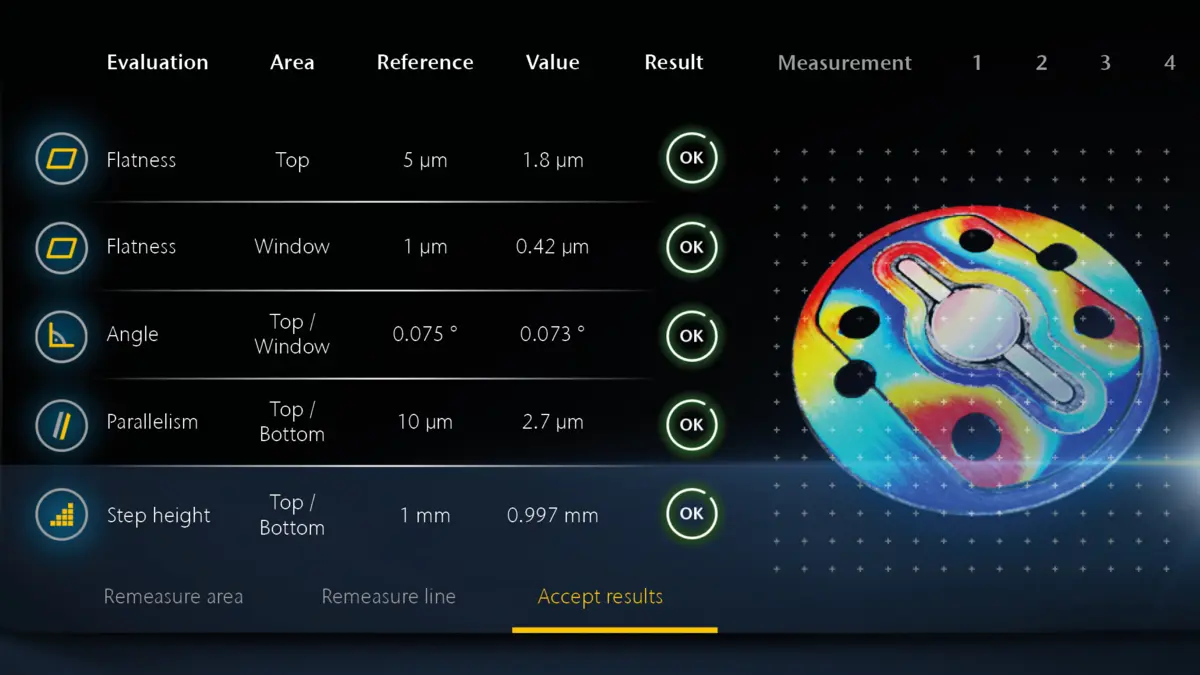

Pass/fail analysis

WLIs deliver fast, objective and easy-to-use pass/fail feedback from areal 3D data. Sub-nanometer Z and recipe-driven workflows support inline SPC.

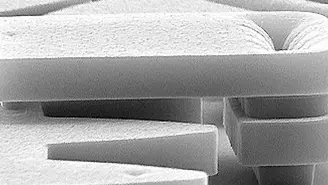

Surface metrology on microstructures

Topography & dynamics of microstructures and for nanotech. 3D geometry, roughness, and time-resolved motion.

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.