Characterizing topography and dynamics of microstructures

Microstructures are very small structures, very often difficult to see with the human eye. During development and production of microsytems and MEMS, inspecting the areal topography allows for checking for defined dimensional tolerances and quality. Typical examples include gyroscopes, pressure sensors, acceleration sensors, micromechanical pumps and more.

The functionality of these surface types can be influenced by small physical changes of defects at micrometer and nanometer levels. Therefore, high-resolution surface inspection is an important aspect of surface characterization in the field of microsystems technology.

Measuring surfaces of microstructures

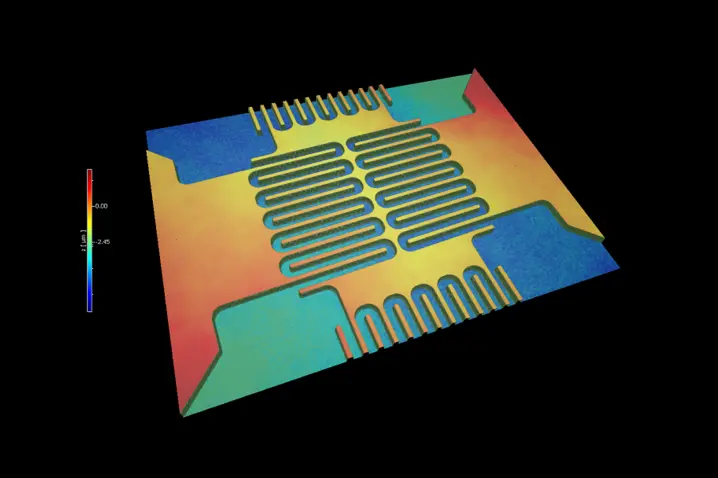

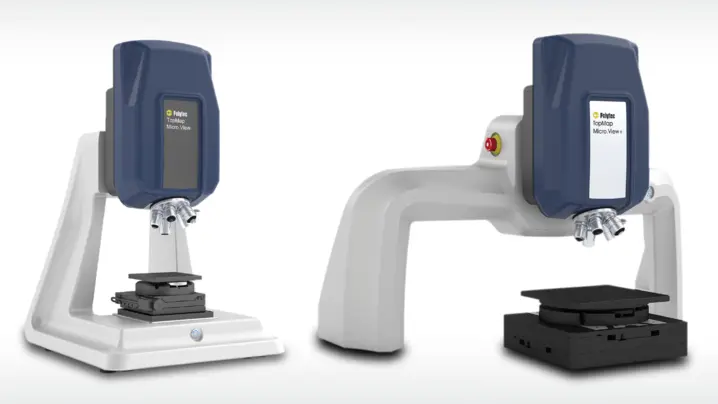

Measuring microstructures demand non-contact systems with a high resolution and focusing and narrow spots (ROIs - regions of interest). With a high-precision profiler as the Micro.View white-light interferometer channel depths on lab-on-a-chip, the step height on MEMS packaging, flatness of pressure sensors and more can be reliable analyzed and documented.

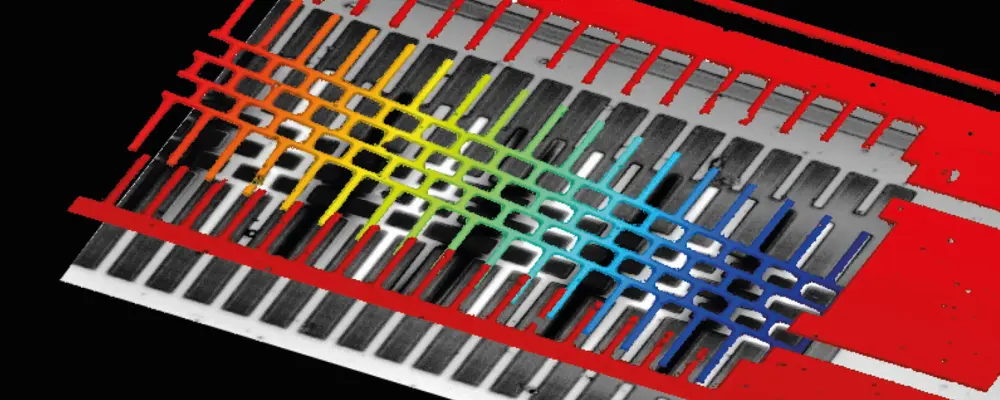

For performing dynamic out-of-plane and in-plane measurements on RF filters to determine MHz resonance frequencies vibrometers can be utilized. For example with the Polytec MSA vibrometers, which even allows analyzing the MEMS dynamic encapsulated in an SI packaging.

Micro.View for surface measurement on microstructures

Discover the high‑precision 3D optical surface profilers, using white‑light interferometry for nanometer resolution and automated workflows.

MSA vibrometers for understanding dynamic behavior

Validate dynamics and topography of microsystems reliably with utmost precision whether in the Kilohertz range, at several Megahertz or up to the Gigahertz range.

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.