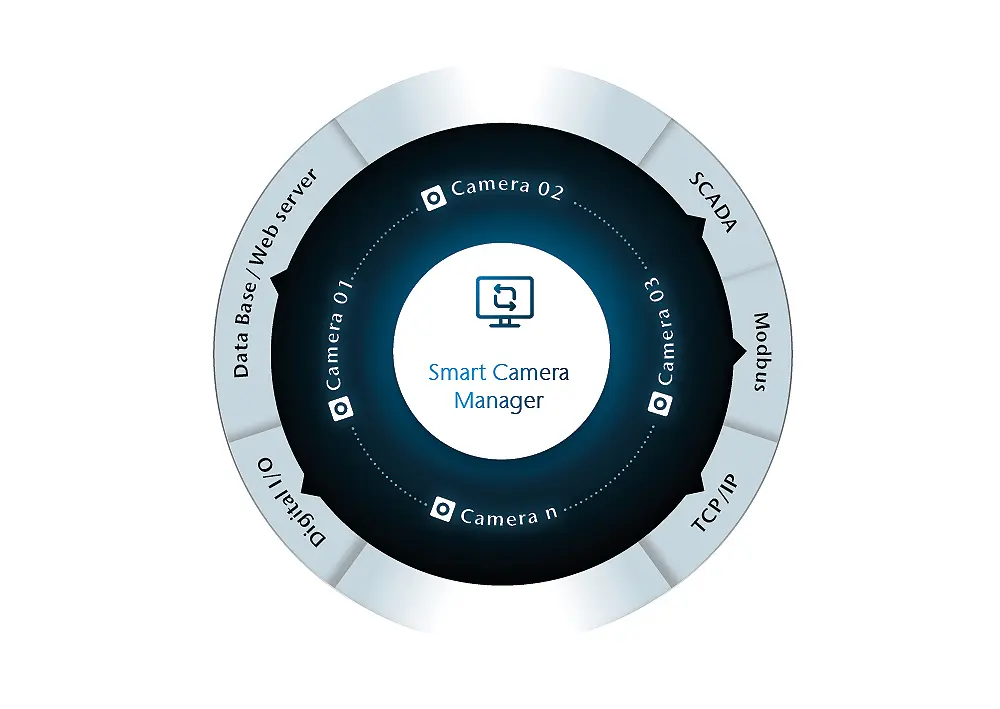

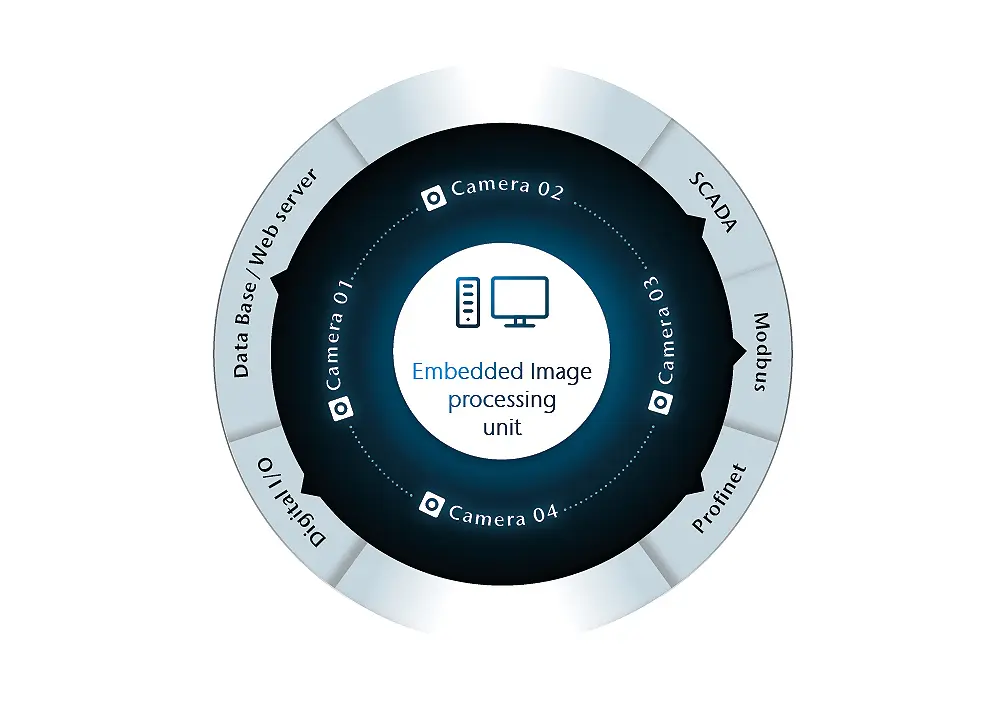

The modular system concept

Thermal imaging solutions from Polytec are based on the IRSX Smartcam and a modular software solution that

- is individually adapted to the application

- is quickly implemented thanks to standardized components

- is easy to certify (VDS, UL, ...)

- remains highly flexible for changes thanks to its modularity

- and offers a high savings potential in terms of development, installation and operating costs and resources

This modular concept can also be applied to different system architectures:

Customized system solutions

Temperature monitoring as a complete solution

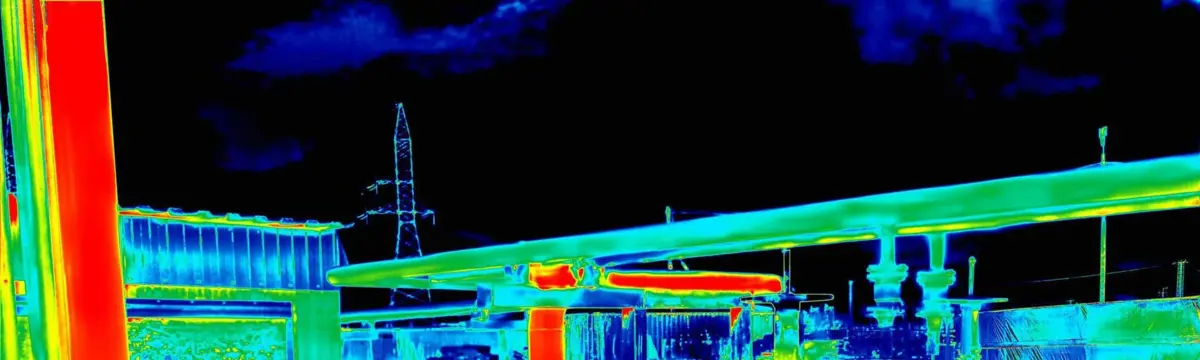

Thermographic methods, whose false-colour images visualize temperatures, are suitable for many areas, e.g. in industry for monitoring temperature-dependent processes. But safety concepts can also often be easily implemented with their help, for example when it comes to detecting heat spots that could lead to explosions in critical environments.

Polytec now offers a complete thermographic system that can be adapted to a wide range of scenarios. It consists of smart, ATEX-approved thermal imaging cameras and modular image processing software tailored to them.

Process monitoring with explosion protection (ATEX)

An international paper group produces toilet paper, household tissues and industrial rolls in a production facility in North Rhine-Westphalia. The energy supply is provided by the company's own coal-fired power plant.

When transporting the coal to the power plant, the requirements of Ex zone 22 apply because the dust in the air could explode due to any embers in the coal. Today, such embers can be reliably detected around the clock using intelligent thermal imaging cameras ...

Turnkey solutions

In addition to various applications such as the monitoring of substations, flame and flare systems or the inspection of electronic components, we offer turnkey solutions for these applications:

Body temperature monitoring

TI FeverScan is a solution for detecting possible fever patients (e.g. corona-infected persons) based on high-precision temperature image evaluation (0.1°C accuracy). The access monitoring system, which is quick to set up and uses a non-contact fever measurement method, can be installed either temporarily in public places or stationary in an entrance area. FeverScan consists of an intelligent IRSX infrared camera, a temperature reference body and a specially developed app. Further advantages: simple installation, fast measurement process (less than 1 second), location-independent use. The graphical representation of the result appears as a simple red-green display on the screen.

The system core - the IRSX Smartcam

The IRSX thermographic camera is the first intelligent, self-contained thermal imaging system that has been consistently developed for industrial use.

The most important features:

- Stand-alone thermal imaging processing, easy to integrate into industrial processes

- Integration without programming effort

- Web-based configuration and visualization

- Consistently suitable for industrial use thanks to robust design, IP67 protection class and industry-standard protocols and interfaces

- Apps available for numerous applications

We will find your solution

Polytec offers numerous possibilities for solving monitoring and quality assurance tasks with infrared technology. As a provider of image processing solutions and an expert in IR technology with a manufacturer-independent product portfolio, we provide the ideal conditions for your individual application. From consultation and evaluation to service, we are always on hand to provide you with advice and support during your decision-making process - just get in touch!