Basics of surface parameters

Very often, mechanical designs for workpieces include specifications for defined surface parameters such as surface roughness or ripple. Polytec TopMap surface metrology based on the white-light interferometry principle acquire entire non-contact 3D areal data in just seconds, where tactile methods would require much longer measuring times. Both 2D and 3D areal surface parameters (ISO 25178-2, ISO 4287, ISO 4288) – can be determined quickly and easily.

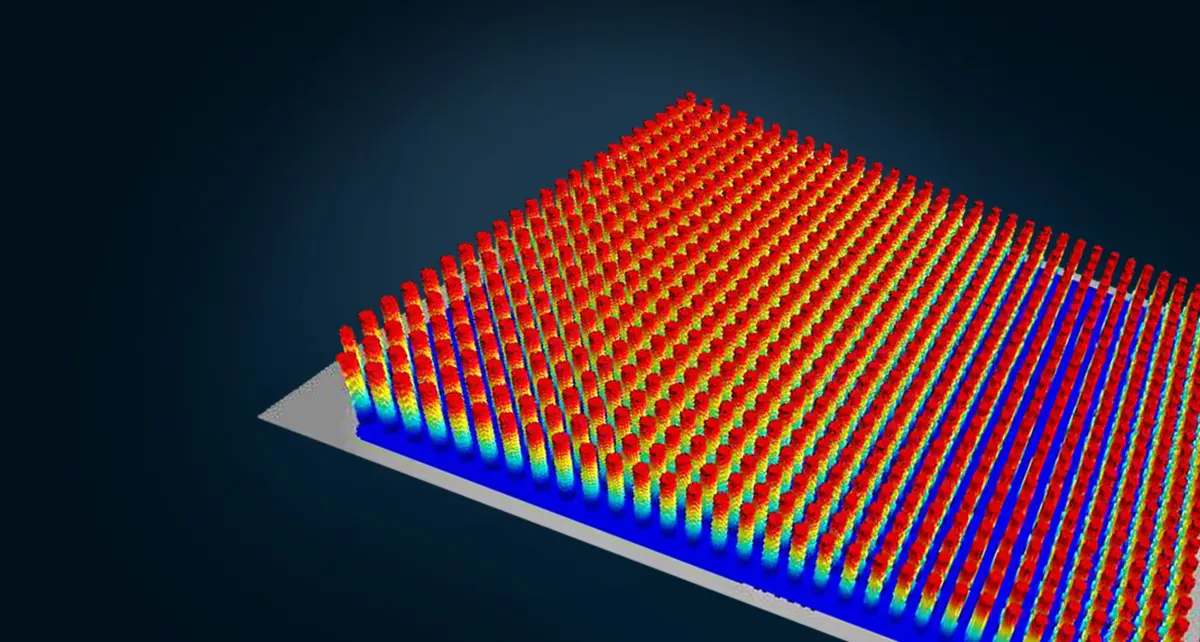

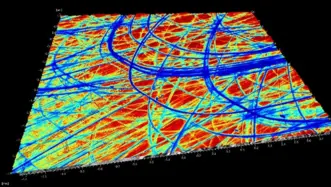

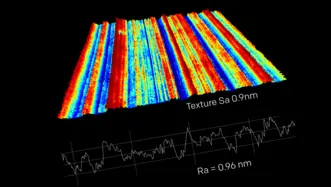

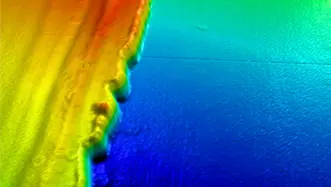

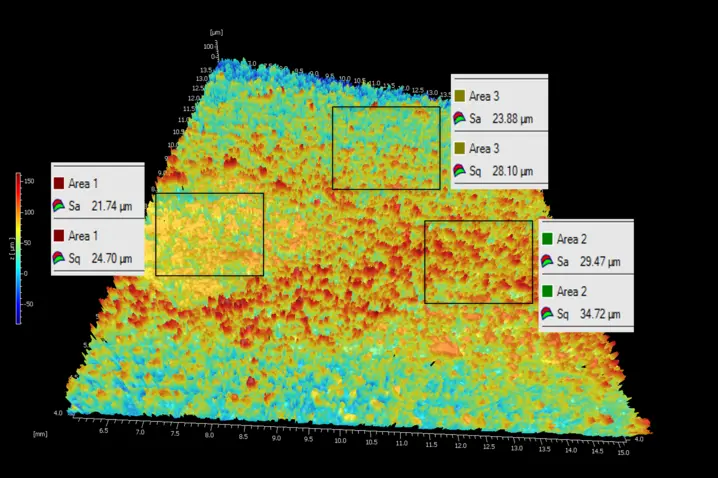

3D areal surface metrology can offer a visual representation of how a surface looks in detail and give a very precise numerical representation, indicating heights and sizes for example.

Although these scales may be very small, they often provide information that directly relates back to how the surface was generated, how to maintain engineering quality or the identification of manufacture defects and failures. Using this measurement feedback allows process control, leading to high quality and consistency of functional and engineered surfaces.

Surface parameters and texture measurement

Table of surface parameter ISO standards

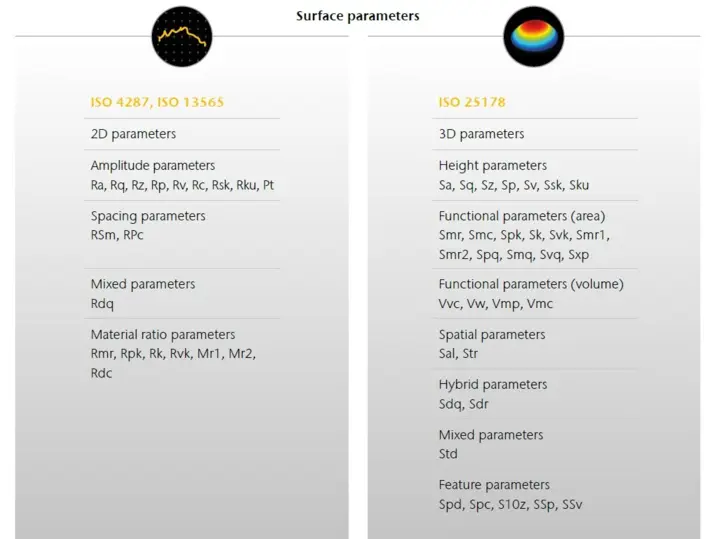

The mathematical description of numerous surface parameters can be found in various international standards. In practical application, ISO 4287 and ISO 13565 for 2D parameters and ISO 25178 for areal surface roughness are of particular importance. These standards define and describe the commonly used texture parameters.

For the large number of parameters from profile standards, an equivalent areal parameter can be found in the published standard. Beyond that, areal topography evaluation offers additional benefit due to third dimension.

The amplitude or height surface parameters frequently used in practice were mostly extended to the areal evaluation. The areal evaluation of the topography shows the advantage of the measuring position being less sensitive than in profile-based evaluations, thus providing more reliable measurement results, especially for inhomogeneous and defective surfaces. However, the surface parameter family as a whole has in common that they cannot represent the functional differences between different types of surfaces. This means that differently manufactured and designed surfaces might still show the same results with respect to the surface parameters.

Our surface metrology portfolio

Micro Profiler

Micro.View profiler systems are optimized for measurements with sub-nanometer resolution. With focused optics and high vertical resolution they enable detailed analysis of microstructures, surface finish and material distribution where even the smallest deviations matter.

Macro Profiler

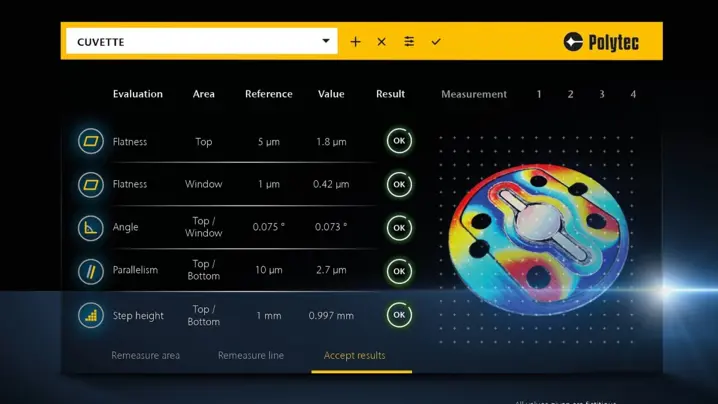

Pro.Surf with its areal topography scanning determines form and flatness faster. Its telecentric optics with large Z range reaches holes and recessed surfaces. The largest FoV and True Stitching handles big samples and multi-sample measurements with ease. Upgrade to Pro.Surf+ and also analyze roughness all-in-one.

Metro.Lab

Metro.Lab is a compact, wide-area surface profiler. It combines high measurement performance with a small footprint—ideal for space or budget conscious applications that still require reliable 3D surface data.

Choose the right surface profiler with confidence—benefit from our "try before buy" approach.

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.