Automation-ready profilometer with Color View

Micro.View+ extends surface roughness inspection into automated, operator-independent workflows for production and quality control. This profilometer combines sub-nanometer precision, a large 100 mm Z-range, and full motorization to deliver fast, repeatable surface measurements — from micro-features to larger components.

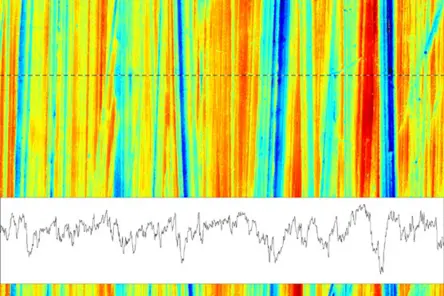

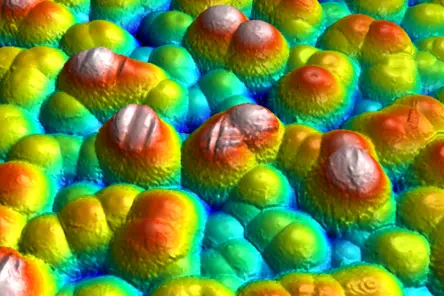

- Reliable surface roughness analysis in sub-nm precision on various materials thanks to Smart Scanning Technology and Color View

- Widest and most variable FoV for flexible roughness analysis (from 0,07 mm bis zu 15,5 x 11,7 mm)

- True Stitching for unmatched accuracy of wider parts

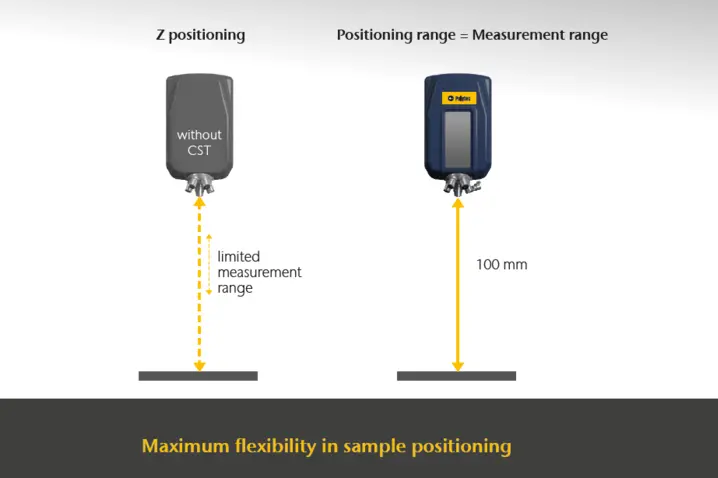

- Wide Z measurement range of 100mm with full resolution due to Continuous Scanning Technology (CST)

- Recipe-driven measurement with Focus Finder for repetitive operations

- Compliant to newest standards (ISO 25178, ISO 21920 and more)

- Operator-independent workflows with Focus Tracker and motorized X, Y, Z, tip/tilt stages and automated turret

- Ready for factory automation due to modular design and interfaces

Micro.View+ is best for applications with increased requirements for automation, serial measurements, or operator-independent workflows. In case automation capabilities and Color View are not demanded, the Micro.View profiler could be another attractive alternative.

Easy profiling of nearly any surface and ready for automated workflows in production or the lab

Measure where others struggle

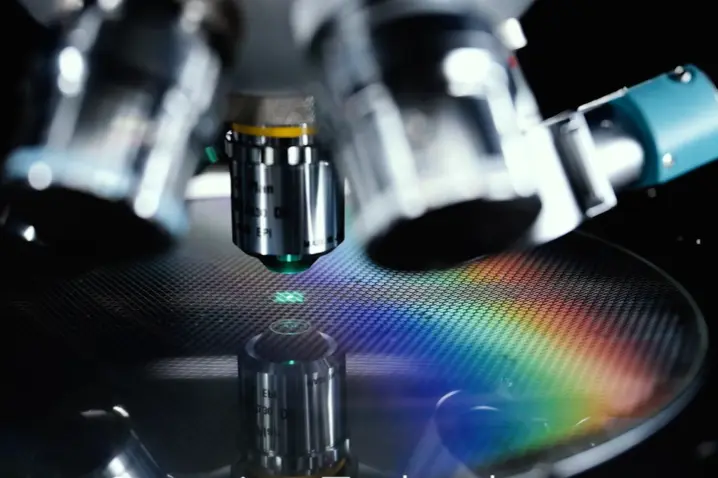

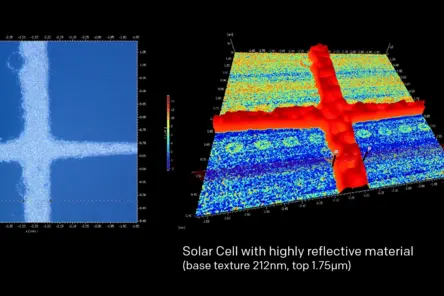

Many optical profilers struggle with highly reflective, dark, low-contrast, or transparent materials. Micro.View overcomes this using embedded correlogram technology, which allows multiple scans at different light intensities. This enables reliable measurements even on complex materials.

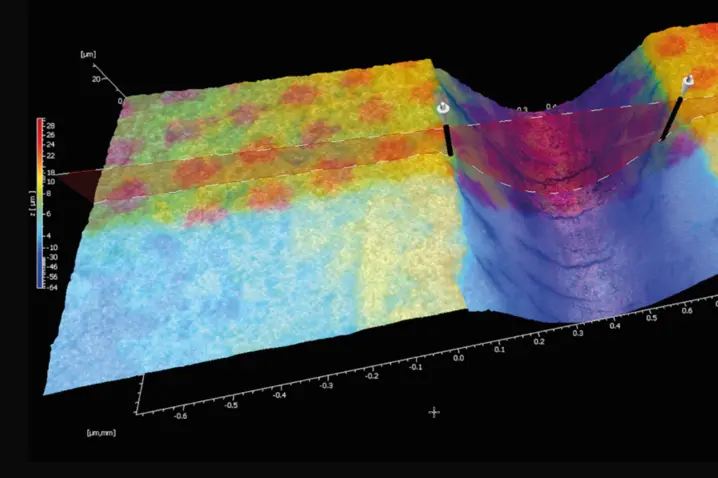

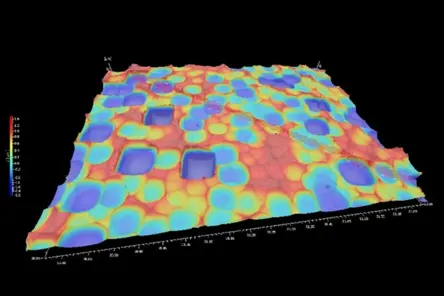

The result: precise 3D data for topography, roughness, microstructures, step heights, and flatness — even on the most challenging surfaces. A key reason customers switch to Polytec is our ability to measure mirror-like or polished surfaces where other systems fail.

Precision by experience

With decades of experience, our engineers combined phase and envelope evaluation of the correlogram with inherently low system noise and our optional Environmental Compensation Technology (ECT). This results in sub-nanometer vertical resolution and outstanding 3D data clarity.

And with our True Stitching, using advanced algorithms (AI), our systems and software deliver an unmatched precision with wider samples.

This level of precision empowers engineers to verify tight tolerances, optimize production, and ensure long-term reliability.

Utilizing the full Z-range

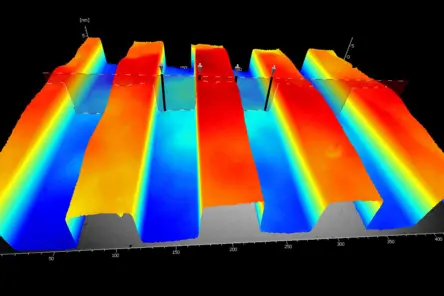

With Continuous Scanning Technology (CST), Micro.View uses the entire 100 mm travel range as usable Z-range — independent of the selected objective. This ensures stable resolution across tall parts and eliminates the need for repositioning.

Different stand options further support larger or taller samples, enabling flexible setup from small research parts to large industrial components.

Easy to measure, solid in documentation.

Micro.View systems are designed for ease of use. Focus Finder and QC recipe tools simplify setup, while CST and ECT ensure stable data without constant adjustment.

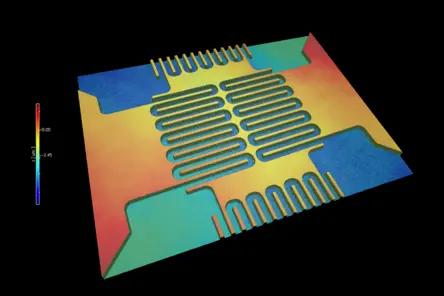

Micro.View+ combines high-resolution 3D topography with color imaging for intuitive visualization of defects or wear. Built-in reporting tools support traceable documentation to make it as easy as possible for your engineering, production, and quality teams.

Platform for reliable automation

Modular Micro.View+ line provides the platform with full motorization (X, Y, Z, tip/tilt), Focus Tracker, and a motorized turret for unattended operation. With QC recipe management, different sample types can be measured with operator-independent quality control and minimal manual effort.

Combined with ECT and built-in vibration isolation, Micro.View+ enables lab-grade precision directly in production lines — with higher throughput and lower operator influence.

Choose the right surface profiler with confidence—benefit from our "try before buy" approach.

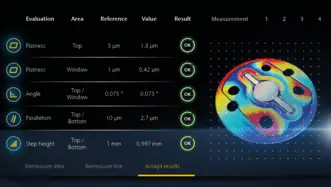

Automated surface measurement: From roughness to tribology with high repeatability

Below or some real-life results from standard tasks (roughness, flatness, step height, texture, tribology) across common engineering materials. Those examples are gathered by our application centers which does feasibility studies and offers contractual measurement services.

Choose the right surface profiler with confidence—get a demonstration of our capabilities.

The 3D profilometer for highest precision with automation capabilities and Color View

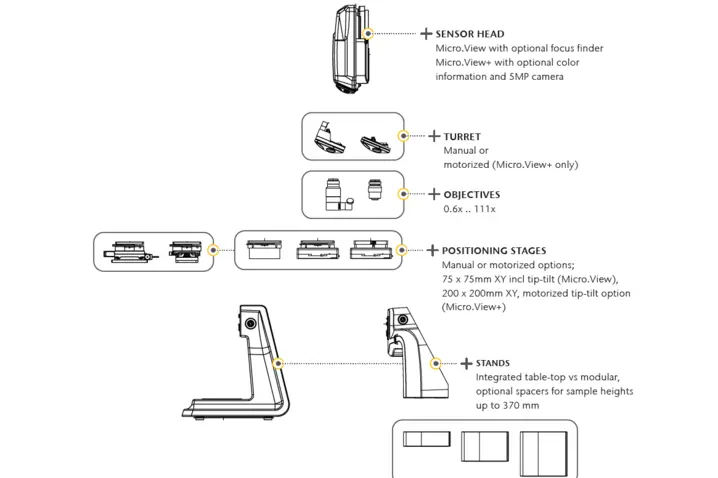

Micro.View+ offers a wide ability for workflow automation and is highly effective for repetitive metrology jobs. Especially with the optional motorized turret and stages - also with tip/tilt feature. Some key features:

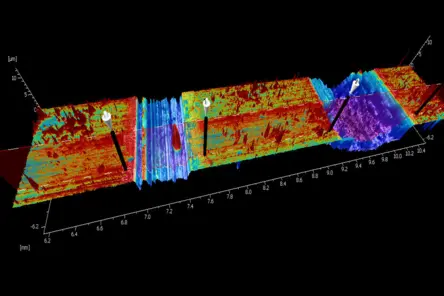

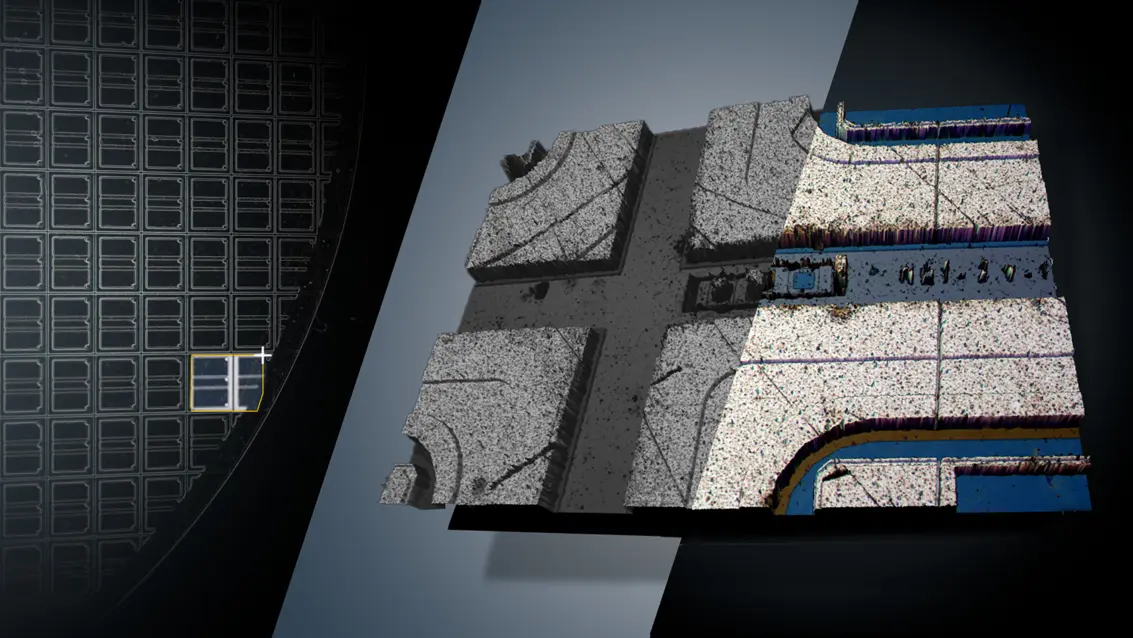

True Stitching - Higher accuracy for wider samples

Because larger surfaces exceed the single-shot field of view — stitching merges tiles into one accurate dataset. The metrology quality of such large-area measurements depends on the optics and sensing technology, the number of tiles and the stitching algorithms.

True Stitching delivers high-fidelity large-area measurements by minimizing stitching artifacts and preserving geometry.

An independent benchmarking at a leading German technical university compared six optical profilers from different manufacturers and the Polytec profilometer demonstrated the highest stitching and measurement quality. This is achieved by various features as:

- Large single-shot FoV → fewer tiles and seams, less cumulative error

- Sophisticated stitching algorithms → controlled overlap, robust registration, and metrology-safe blending that preserves steps and edges

The result is high-fidelity, large-area topography with fewer artifacts and audit-ready residuals—what we call True Stitching.

Focus Finder & Focus Tracker - Every measurement in focus, always.

Accurate focus is critical for surface metrology.

- Focus Finder (standard): automatically detects optimal focus point to reduce setup time

- Focus Tracker (Micro.View+): keeps the surface in focus during movement — ideal for stitching and automation

This ensures stable focus across all measurements, even on uneven or moving surfaces.

Color View for a better understanding of the surface features

Hardware option to enhance 3D measurements with a color image of the surface.

- Easier identification of defects or wear

- Supports documentation and reporting

Sub-nm surface roughness inspection with large FoV

Widest Field of View - up to 15.5 x 11.7 mm

The new and unique 0.6x lens literally expands your view: Micro.View allows the analysis of high-resolution surface roughness, texture or microstructures using classic 20x to 111x. A single click with automatic lens switch to 0.6x allows for a seamless transition to large-area form or flatness measurements. Examine microstructures on large scale without stitching. Reveal all structural details while keeping an eye on form parameters, warpage or large area steps.

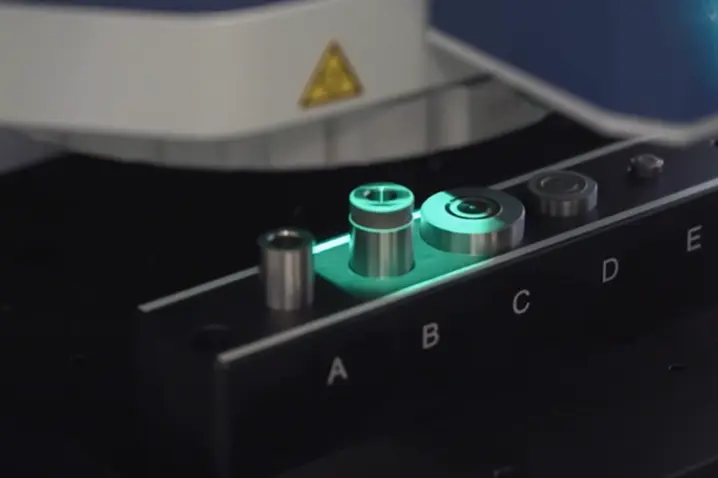

Motorization & automation - for shopfloor efficiency.

Micro.View+ adds full motorization for maximum flexibility and repeatability. Ideal for production environments or recurring measurement tasks.

- Motorized turret for up to five encoded objectives

- Motorized X, Y, Z, tip/tilt stages

- Automated stitching for high-resolution scans over large areas

- QC recipe system for operator-independent workflows

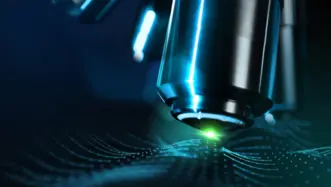

CSI – coherence scanning interferometry for highest precision.

Micro.View is based on CSI (also called white-light interferometry), the industry standard for non-contact, areal surface metrology. It scans a broadband light source vertically and analyzes the interference pattern.

- Envelope evaluation: robust on rough and low-contrast surfaces

- Phase evaluation: sub-nanometer resolution on smooth, flat samples

- Correlogram analysis: full use of the interference pattern for maximum robustness and accuracy

This allows measurement of both polished optics and rough technical parts with the same system.

CST – full 100 mm Z-range without sacrificing resolution.

Continuous Scanning Technology (CST) transforms the entire 100 mm travel range into usable Z-range with consistent resolution — independent of lens.

- Supports large and tall samples without repositioning

- Maintains accuracy throughout the measurement range

- Reduces setup effort and avoids stitching or refocusing

ECT – stable 3D surface data on the shop floor.

Noise, vibration, and temperature fluctuations can affect measurements. Our Environmental Compensation Technology (ECT) compensates for such disturbances and ensures consistent data — even on the shop floor.

- Improves reliability in noisy or unstable environments

- Enables automation and inline QC without full isolation

- Especially helpful for sensitive components (e.g., MEMS, thin films)

ECT and CST

Environment Compensation and Continues Scanning Technology to support easy and unattended measurements

Smart Scanning Technology

SST supports measurement of reflective or matte surfaces

Versatile stages

Motorized xy stages with up to 200 x 200 mm travel.

Manual or motorized tip/tilt feature.

Focus Tracker

Manages focus when using tip/tilt stages to ensure optimized resolution and repeatability.

Encoded turret

Motorized or manual 5-port turret with Focus Finder & Focus Tracker.

100mm Z-Range

100mm z-range (equals measurement range) with Continous Scanning Technology (CST).

Height can be extended with different stands.

Color View

1.9 MP camera provides colored images of samples to support enhanced visualization for e.g. defect detection.

Choose the right surface profiler with confidence—let us run a feasibility study with your sample.

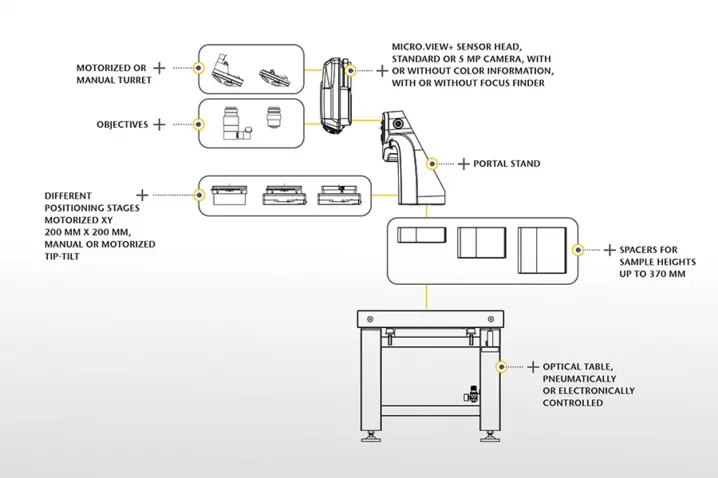

Modular setup, specification and options

| Z Range | 100 mm (positioning & measurement) |

| Vertical resolution | 0.01 nm |

| Repeatability of RMS | 0.05 nm |

| Sample reflectivity | 0.05 to 100 % |

| Measuring points X-Y pixels | 1.910.400 (effective pixels) 1.592 x 1200 |

| Measuring speed | Up to 100 µm/s |

| Stitching | Up to 500 million data points |

| ISO parameters | ISO 25178, ASME B46.1, ISO 4287, ISO 13565, ISO 21920 |

Micro.View+

For large samples with maximized flexibility and motorized 200 x 200 mm xy stage.

Micro.View+C (compact)

Compact tabletop device with motorized 75 x 75 mm or 100 x 100 mm xy stage.

Downloads

Feasibility check?

Send us your sample and we run a feasibility study with our profiler and walk with your through the results.

This gives you a precise understanding of the optical profiler’s performance on your actual samples.

Relevant stories

Micro.View and Pro.Surf measure roughness - so what is the difference?

While Micro.View also supports form, flatness and step height measurements, its core strength lies in high-resolution 3D surface roughness and texture analysis.

The Pro.Surf+ has the reverse approach. Strength is flatness, parallelism and form inspection but also can run surface roughness analysis with a lateral resolution of 2.6 µm.

White light interferometer

Introduction of the white light interferometry technology and the benefits for non-contact areal surface measurement.

ISO 21920 roughness

ISO 21920 is the new standard for mechanical engineering, design and roughness specifications

Measurement tasks

With a WLI optical profiler you can handle all the surface measurement tasks - from surface form parameters, roughness and specific tasks as thickness of layers and coatings.

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.