Length measurement on roll-fed material, sheets and piece goods

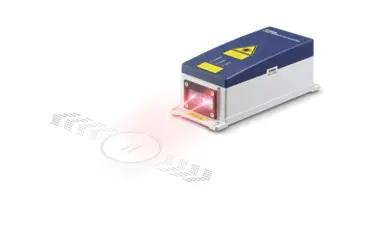

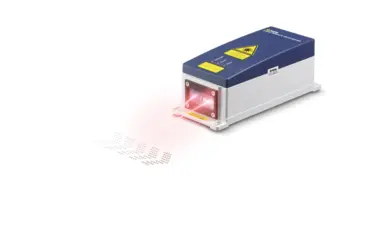

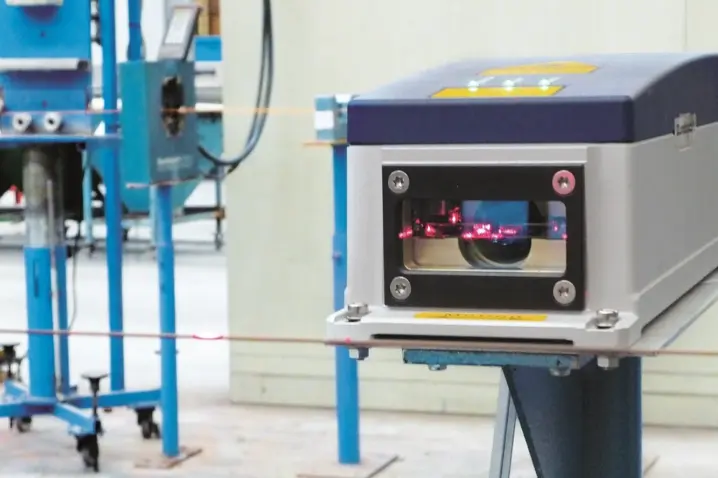

Determining the real-time velocity provides the basis for measuring the length. The length is calculated based on the velocity profile while the measured object passes through the measuring location. LSV Laser Surface Velocimeter are laser-based length and speed sensors, automatically detecting material and triggering start/stop of length measurements. For enhanced process control, connect light barriers as triggers.

LSV Laser Surface Velocimeters are the ideal inline sensor, measuring on almost any surface including challenging and contaminated surfaces in dusty or hot production environments. The non-contact measuring principle avoids measurement uncertainty caused by slippage and wear like with length encoders. LSV optical length sensors avoid any influence on the material surface and can easily be integrated into PLC and prdocution systems with all common (serial) interfaces, LAN, ProfiBus or ProfiNET.

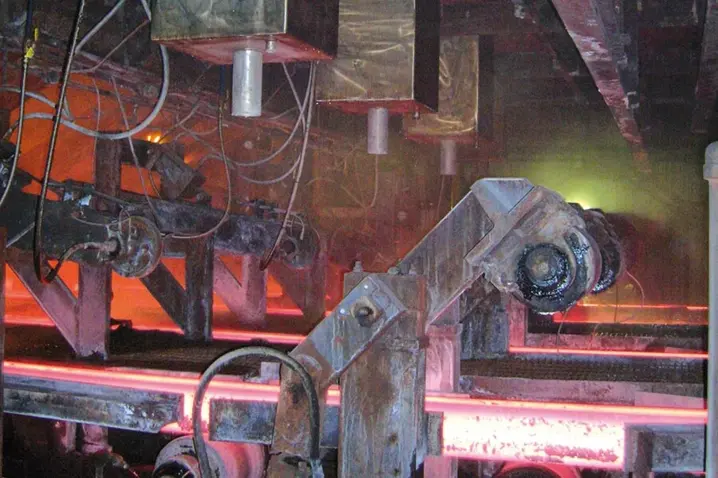

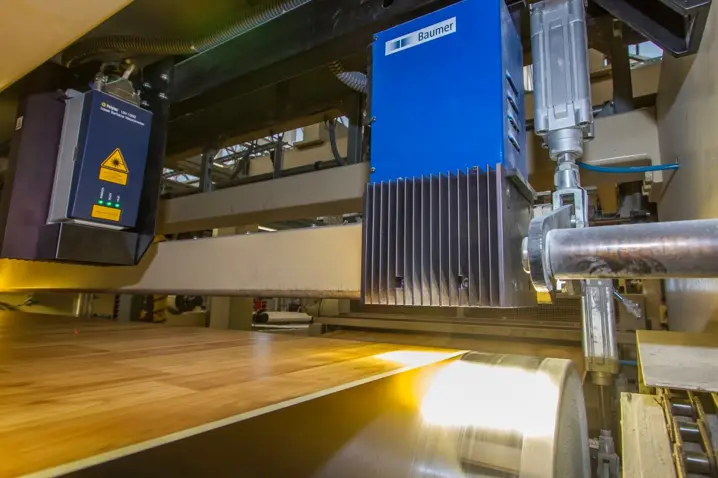

Measure length of metal sheets, on red-hot steel and rolling mills

Polytec LSVs are used worldwide for a variety of length measurement tasks in metal, steel, titanium or aluminum manufacturing lines:

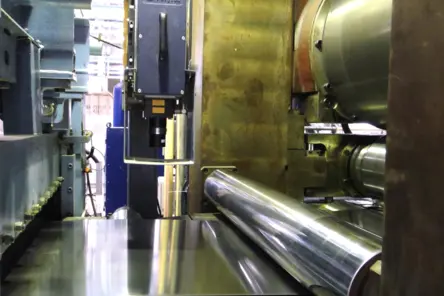

- Rolling mills worldwide use LSV sensors for measuring the speed and length of rolled strip material, for (AGC) mass flow control and support C gauge integrated thickness measurements or roll gap control.

- Continuous casting lines rely on laser precise data for process control and torch cutting/ cut-to-length control.

- Extreme temperature applications like red-hot steel blooms up to 1.000°C with non-contact measurement from a safe distance.

- Cut length control of flying or vertical saws and shears, or rotary tube saws.

- Length verification of end products, e.g. cut length of bars, pipes, coils, plates and blanks.

- Positioning of plates in U/O presses for longitudinally welded, often large-diameter tubes.

Optical length & speed measurement for ultimate precision process control

Length of paper, cardboard & packaging

- Length measurement of coils or non-wovens

- Measuring length of cut pieces / units sold by length

- Position tracking for printing, coating or finishing

- Controlling the cut length and speed of cardboards and packaging material

The laser is actually unbeatable!

Length of construction material & lumber

- Rolling up web material

- Checking cut to size pieces (part length inspection)

- Position sensing in printing and marking processes

- Position monitoring for NDT, defect detection, or marking, printing and labeling jobs

LSV Laser Surface Velocimeters are the preferred solution for precise length measurement e.g. for fiber cement, plasterboard, wood products, glass or mineral wool or roofing materials.

Length of cable & wire

- Cut-to-length and winding of cable, wire and fibres

- Position sensing in printing and marking processes

- Coil winding

- Wire drawing

- Insulating and sheathing lines

Length in converting & textiles

- Winding (coiled) sheet materials

- Cutting-to-length during fabrication

- Position sensing in printing processes

In a case study, a world leading manufacturer of conveyor and drive belts uses several Polytec LSVs for inline monitoring of length at the cutting stations. This allows for automizing customer-specific cuts, leading to significant process improvement with cut-to-length accuracies independent of the belt surface around 0.1%.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters — get in touch with us today.