Your software for in-depth surface research and efficient production quality control. Free lifetime updates!

Polytec TMS is the holistic Topography Measurement Software for the TopMap profiler line. The TMS Software acquires, filters, visualizes, analyzes and documents form and roughness measurement data. Its open architecture allows application-specific add-ons and vast automation. Ask for options, like:

- QC Operator Interface as one-click solution for production level, using measurement recipes for recurring inspections

- QC Verifier with patented ECT Environmental Compensation Technology ensures stable precision measurements on "noisy" shop floor

- QC Settings Comparator for standardization and simplified monitoring of measurement settings across different production sites/ lines

- TMS Viewer as lightweight result viewing & sharing

- Polytec Update as streamlined service tool for updates

- SDK Software Development Kit for generating custom and application-specific routines

Together, these modules support both quick inspections and deep research analysis as efficient, traceable quality control.

TopMap QC Package for quality inspection in production

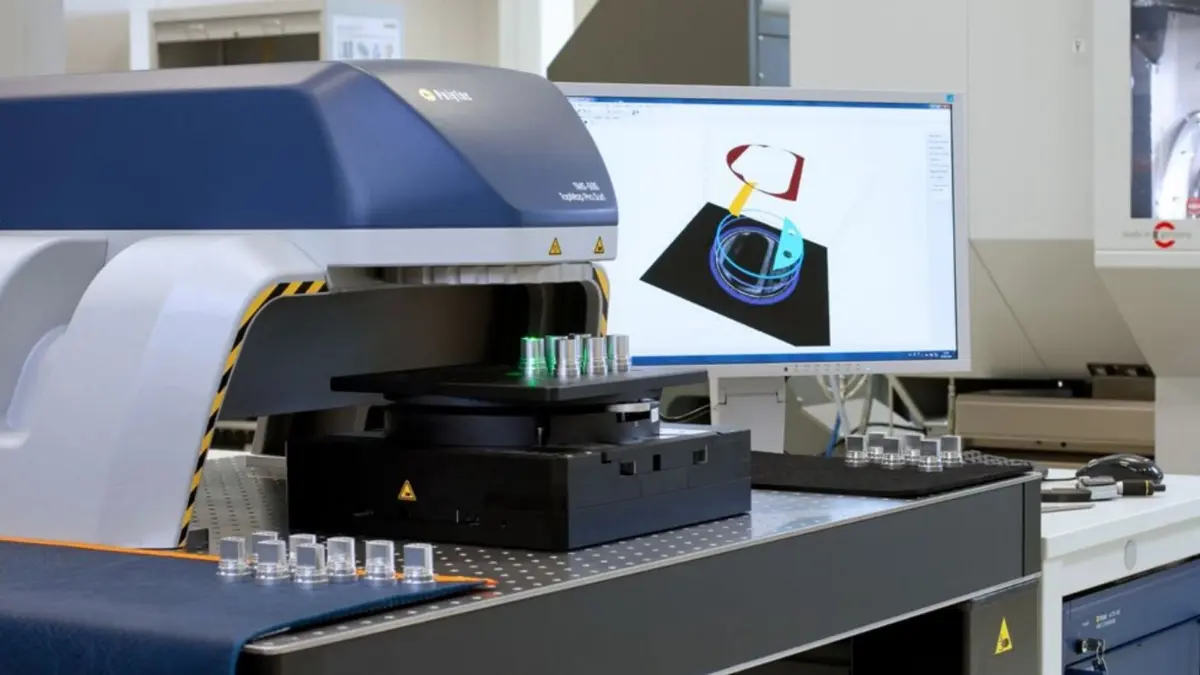

TopMap surface metrology systems are designed to monitor manufacturing processes, assuring that production tolerances and process capabilities are met. The QC Package includes smart features and upgrade options for quality control tasks, especially for real-life production testing. Learn more about how the QC Package supports 3D surface inspections, especially in challenging production environments.

Innovative ECT Environmental Compensation Technology for clear results in noisy manufacturing

On the factory floor, vibration, airflow, and part motion can become challenging influences, disturbing precision measurements leading to false rejects. The QC Verifier delivers reliable pass/fail decisions on the line, reducing false rejects and scrap. Its patented ECT Environmental Compensation Technology isolates precision measurements from factory-floor disturbances such as vibration, noise, and motion, delivering stable and repeatable measurement results. Test ECT for clear pass-fail decisions.

Choose the right surface profiler with confidence—get a demonstration of our capabilities.

From surface metrology to comprehensive topgraphy analysis

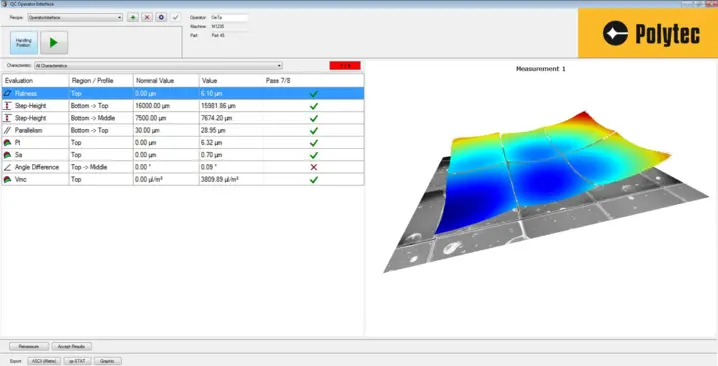

The TMS Software for Polytecs topography measurement systems (TMS) of the TopMap series offers a wide range of features and options for quick and easy routine measurements but also for your extensive and detailed surface analysis:

- Interference Finder automatically detects your surface under test

- SST Smart Scanning Technology enables measurements on surfaces with varying reflectivity and contrast properties

- Work with masks, profiles and layers

- Evaluation in terms of many different 2D and 3D surface parameters

- Multitude of exportable characteristic values according to e.g. QS-Stat

- Creation of a task-specific user interface with application-specific add-ins

- Geometric evaluation options for sphere matching and for determination of step heights, layer thicknesses and volume

- Expanded maximum lateral measurement area by faster assembling of several measurements (stitching)

- Expanded reporting option sent results

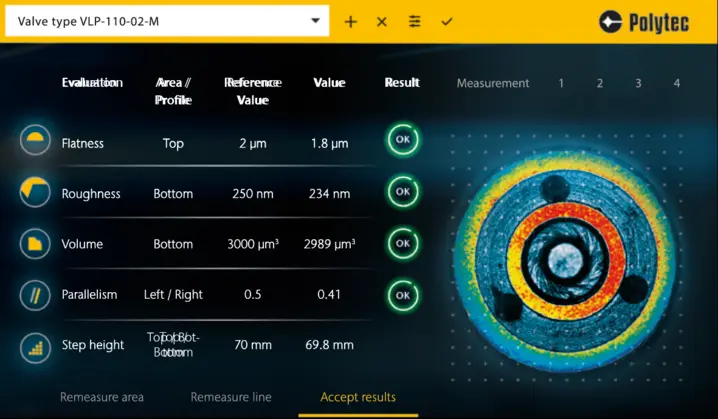

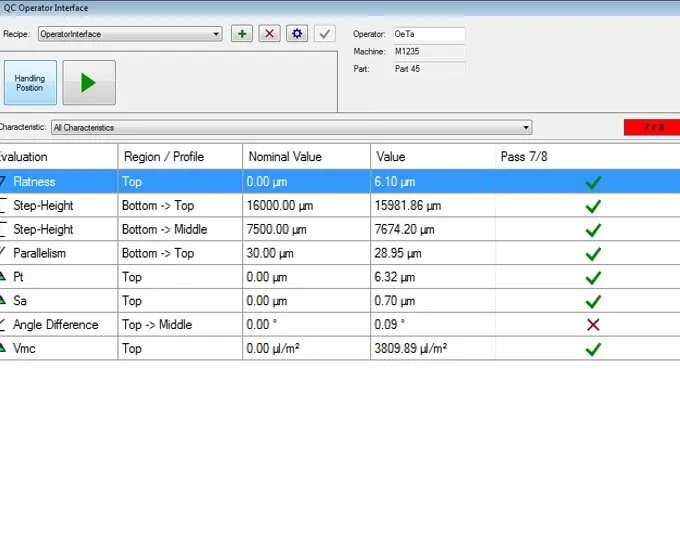

QC Operator Interface: one-click solution for production level

The QC Operator Interfaces manages your "measurement recipes" simplifying the definition of all acquisition settings and evaluation parameters significantly.

Define, adjust and save acquisiton settings like measurement position, illumination, camera parameters. Setup and save evaluation settings like post-processing steps, visualization possibilities, export options and later even reporting for any specific measurement task.

The measurement recipe is especially helpful in manufacturing environments, for routine inspections and recurring tests as one-click solutions, also for untrained workers.

Tailored to your needs

Industrial production benefits from tightly integrating surface metrology into the manufacturing process. Only then, the inspection feedback allows immediate and cost-efficient reactions.

TopMap surface metrology systems from Polytec help adjusting manufacturing parameters, assure to stay within production tolerances and improve your process capability.

Enabling software for efficient workflows

Industrial production benefits from tightly integrating surface metrology into the manufacturing process. Only then, the inspection feedback allows immediate and cost-efficient reactions. TopMap surface metrology systems from Polytec help adjusting manufacturing parameters, assure to stay within production tolerances and improve your process capability.

Customized hardware & systems

Polytec offers turn-key solutions with individually customized hardware and software solutions based on your specific needs. For example, optional glas compensation to measure through transparent materials.

With the modular architecture the hardware, the advanced software and integration capabilities, in- and at-line systems can be optimized for customer demands.

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.