Form and position tolerances in precision components

When manufacturing components, increasingly tight production tolerances must be met — particularly on technical and functional precision surfaces. Manufacturers therefore need to verify form tolerances such as waviness or flatness, as well as position tolerances such as parallelism and tilt, with high accuracy. This ensures compliance with specifications and reliable delivery within defined timeframes.

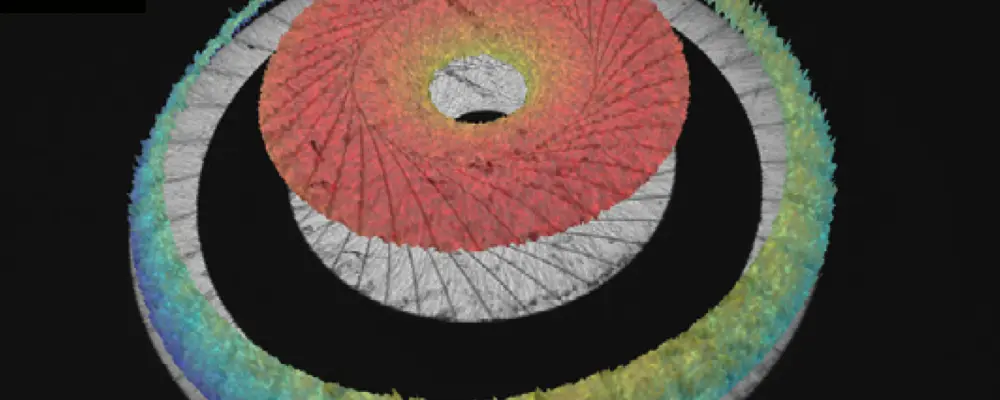

In many cases, manufacturers inspect the complete surface topography of a component to verify compliance with form and position tolerances — for example in shock absorber components, other precision parts in the automotive and aerospace industries, or in fine mechanics.

Verifying form and position tolerances

White-light interferometry measure form parameters such as flatness, parallelism and step-height faster and more efficient even with large samples. Working great on materials of different reflectivity, such as shiny polished metals, or dull ceramics makes them the flexible choice for lab and production. Requirements for component warpage (e.g., printed circuit boards) also continue to increase as geometries shrink.

In addition, many applications involve challenging geometries: areas of interest may be located inside deep bores or show significant height differences between functional areas. Here, Polytec systems based on proven white-light interferometry deliver reliable results — where other optical measurement methods face limitations.

Polytec white-light interferometers perform repeatable, non-destructive measurements with resolutions of only a few nanometers — and even sub-nanometer capability. Optical profilers are ideally suited for the precise determination of form parameters such as flatness and parallelism — supporting efficient verification and easy integration into inline inspection workflows for form and position tolerances.

Optical profilers for tolerance verification

Polytec provides optical systems for measuring the topography of large surfaces with nanometer-level vertical resolution. This high vertical resolution is independent of the field of view, enabling stable measurement results across different sample sizes and inspection setups. Typical measurement tasks include determining flatness, step height, roughness, parallelism, and other surface parameters required to comply with form and position tolerances.

Micro Profiler

Micro.View profiler systems are optimized for measurements with sub-nanometer resolution. With focused optics and high vertical resolution they enable detailed analysis of microstructures, surface finish and material distribution where even the smallest deviations matter.

Macro Profiler

Pro.Surf with its areal topography scanning determines form and flatness faster. Its telecentric optics with large Z range reaches holes and recessed surfaces. The largest FoV and True Stitching handles big samples and multi-sample measurements with ease. Upgrade to Pro.Surf+ and also analyze roughness all-in-one.

Metro.Lab

Metro.Lab is a compact, wide-area surface profiler. It combines high measurement performance with a small footprint—ideal for space or budget conscious applications that still require reliable 3D surface data.

Choose the right surface profiler with confidence—benefit from our "try before buy" approach.

Related articles

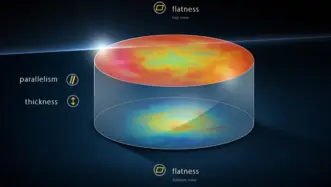

Flatness, thickness and parallelism

Flatness, thickness and parallelism (FTP) measurement combines top & bottom topography measurement in a single shot.

Pass/fail analysis

WLIs deliver fast, objective and easy-to-use pass/fail feedback from areal 3D data. Sub-nanometer Z and recipe-driven workflows support inline SPC.

"Try before buy" offer

Measure, rent, decide - on your terms. Make a confident decision about which surface profiler fits into your metrology strategy and safeguard your capital investment.

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.