Stroboscopic video microscopy

Stroboscopic video microscopy (SVM) makes use of the fact that high-frequency vibrations at component level can be visualized with normal video cameras when rapid movements are visually frozen using short flashes of light.

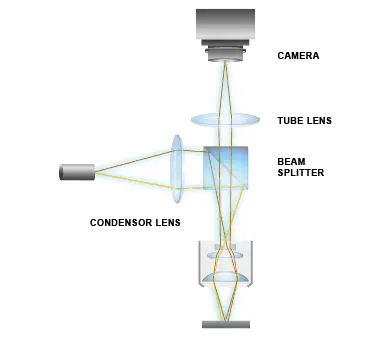

The system’s temporal resolution capacity is determined by means of the LED strobe’s flash pulse width, as the camera isn’t quick enough to clearly record very fast events. If the strobe light is switched off, the CCD sensor cannot capture any images, and this is precisely why light is only recorded during selected movement phases when the strobe light is switched on and why events can be recorded over a period of time shorter than the camera’s shortest possible exposure time. The excitation signal that causes the sample to vibrate, the LED strobe flashes and the camera exposure time must all be exactly coordinated to one another as regards time. The image below shows the time diagram for synchronizing the PMA software, taking the example of two camera shots during two different phases of periodic sample excitation.

Combination with laser Doppler vibrometry

You can use a combined stroboscopic video microscopy (SVM) and laser Doppler vibrometer (LDV) system to identify the mechanical resonances of structures that move in all three spatial directions. The laser beam of a laser doppler vibrometer and the strobe light are coupled into the integrated microscope lens’ beam path using beam splitter units. Working in conjunction with the signal generator and the vibrometer controller, the computer controls the laser beam’s movement (scanning LDV or SLDV), the strobe lighting, processing of the interferometric signals and the camera image, and (if necessary) the sample excitation too. The measurements are ultimately evaluated and graphically represented using the high-performance system software.

The combined method is particularly significant with respect to characterizing micromechanical components (MEMS).

Basic principles of laser Doppler vibrometry

Related products

MSA-650 IRIS Micro System Analyzer

The innovative and patented MSA-650 IRIS Micro System Analyzer with IR capability allows for measuring true MEMS dynamics up to 25 MHz by characterizing both in-plane and out-of-plane motions through silicon encapsulation without contact, without need for preparing nor decapping the device.

MSA-600 Micro System Analyzer

The all-in-one optical measurement solution for static and dynamic 3D characterization of MEMS and microstructures- now for up to 8 GHz! The MSA-600 enhances microsystem development and quality inspections - also allowing testing on wafer-level when integrated into commercially available probe stations.

MSA-100-3D Micro System Analyzer

The 3D Micro System Analyzer records vibration components in all three spatial directions at once. The optical measurement system enables high-resolution 3D vibration analysis from DC up to 25 MHz with amplitude resolutions in the sub-picometer range, for both in-plane and out-of-plane vibration components.

MSA-060 Micro System Analyzer

Use the MSA-060 for entering the world of microsystem analysis. Record and visualize vibrations and dynamics of small components and microsystems with laser precision over an entire surface from DC to 24 MHz. Micro System Analyzers use measurement lasers, revealing the true dynamics of small components in a completely non-contact and non-invasive way.