Inspect topographies faster with large FoV.

4 year warranty included.

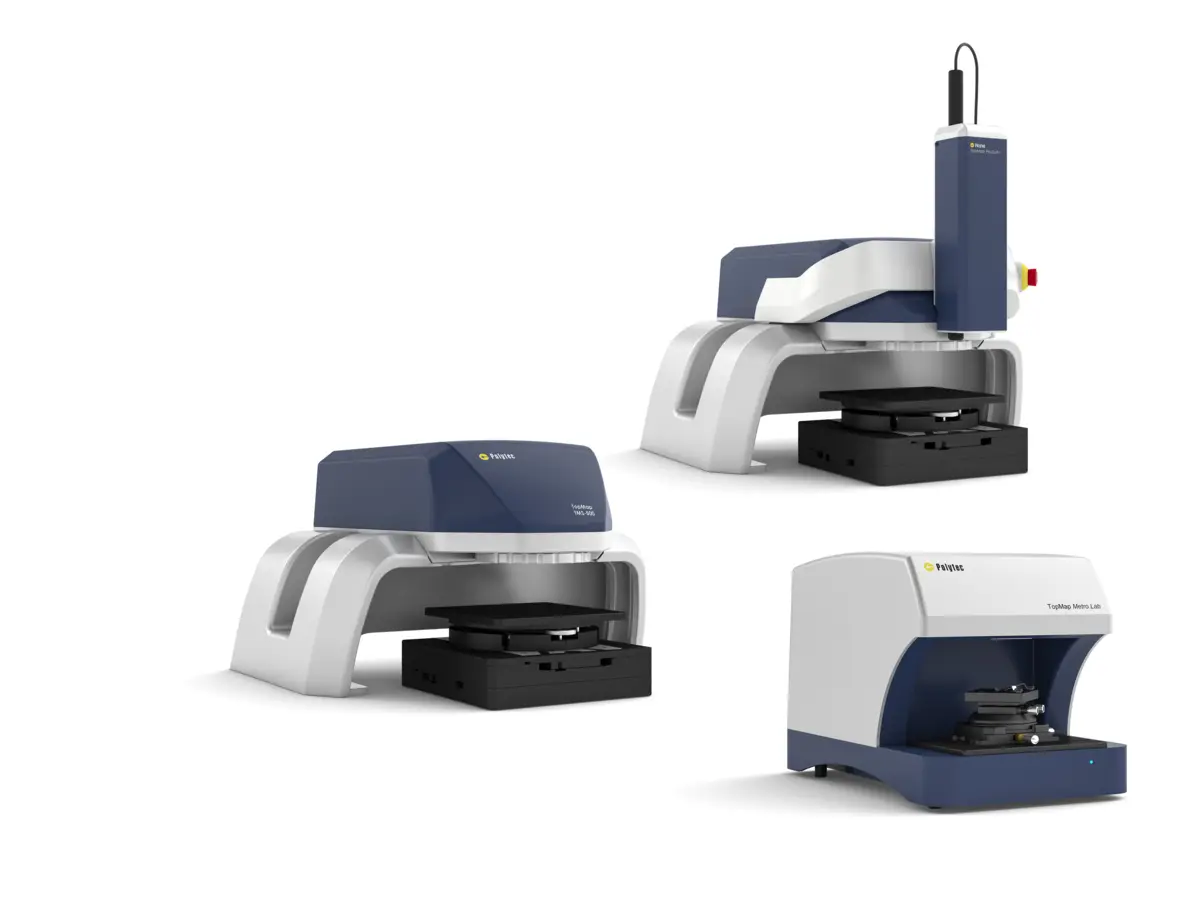

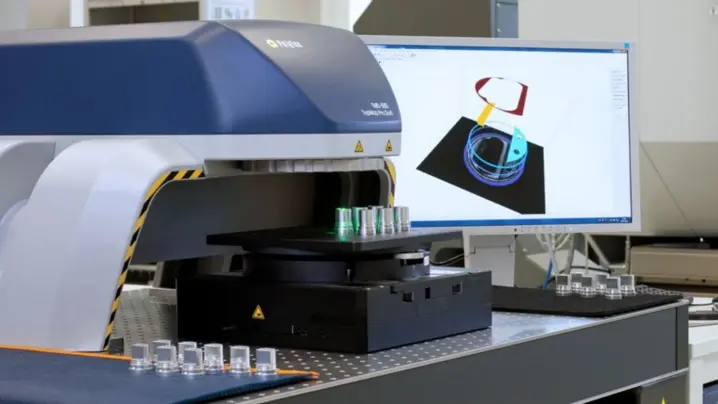

Regarding large area profiling, the Pro.Surf stands out of the crowd by combining ultra-fast scanning with telecentric optics, exceptionally large field of view, and production-ready testing performance — even on big samples, larger areas, trays, and recessed sections. With Metro.Lab we offer a compact system for quick quality checks in production.

Our macro profiler combine telecentric white-light interferometry with a large optical Z range to address form and flatness measurement tasks with higher throughout:

- Fast, areal form and flatness measurement with a large single-shot field of view (up to 44 × 33 mm) and True Stitching for extended scan areas

- Reliable inspection of steps, bores, and recessed features using telecentric optics and large 70 mm Z scan range

- Combined form and roughness measurement all-in-one profiler Pro.Surf+ adds an integrated chromatic-confocal roughness sensor

- Repeatable, traceable quality control through recipe-based workflows, automation options, and ISO-compliant evaluations

- Production-ready operation supported by the patented ECT Environmental Compensation Technology for stable results at production level

The speed, robustness, and repeatability make Pro.Surf a strong choice for applications in precision manufacturing, automotive and mechanical engineering, optics, semiconductor production, and quality control— especially where tight form tolerances meet short cycle times like in manufacturing lines.

Some key facts

Which macro profiler fits your large-area metrology task best?

The Pro.Surf product line is designed for fast, non-contact form and flatness inspection on large components, trays, and recessed features. With telecentric optics, a large single-shot field of view, and automation-ready workflows, Pro.Surf systems deliver reliable 3D surface data directly in production and quality control environments.

Choose the right macro profiler system based on whether your application focuses on

- form and flatness inspection in an efficient way (Pro.Surf)

- requires combined form, flatness and roughness measurement in one station (Pro.Surf+)

- time-to-time inspection of smaller parts with a compact system (Metro.Lab)

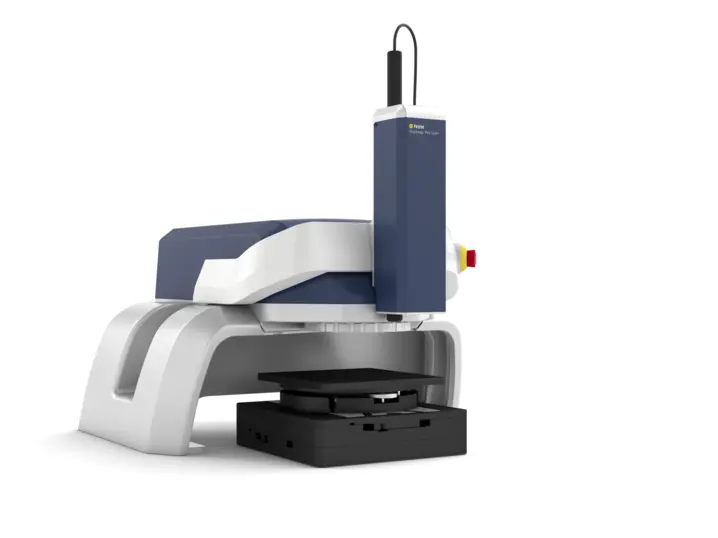

Pro.Surf

Telecentric large-area optical profiler for fast, repeatable form and flatness inspection.

- Large single-shot FoV for trays and multi-part measurements

- 70 mm Z range for large steps and recessed features

- Resolution in the nanometer range over the full Z range

- True Stitching for high-accuracy large-area scans

- Automation-ready with recipe control and barcode start

Best fit for high-throughput quality control, production metrology, and form inspection on large precision components.

Pro.Surf+

Adds integrated roughness measurement to large-area form inspection—all in one system.

- Includes all Pro.Surf features, plus:

- Integrated chromatic-confocal roughness sensor

- Combined form and roughness measurement in a single workflow

Best choice when form and surface roughness must be evaluated together without changing setups or measurement stations.

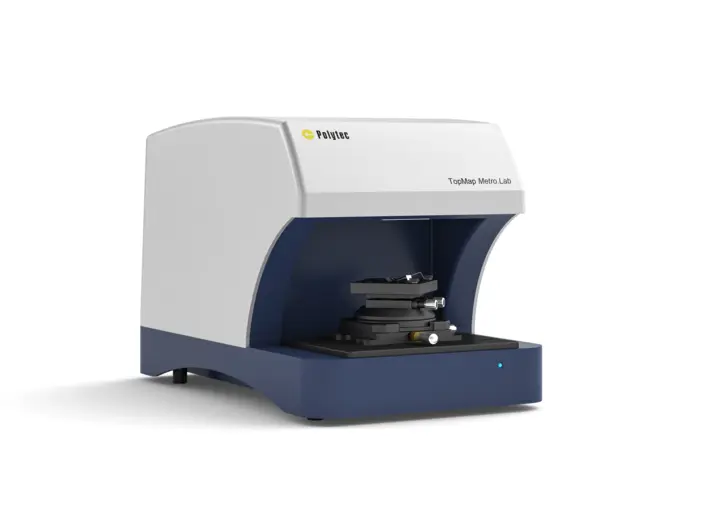

Metro.Lab

As Pro.Surf, the Metro.Lab platform combines large-area optics, long Z scan range and ISO-aligned software for precise, repeatable measurements—but in a compact form.

- Broad field of view (37 × 28 mm with stitching 87 × 78 mm)

- 70 mm vertical range with high resolution

- Operator support with recipes and barcode scanner connectivity

Ideal for random sampling of small to medium-sized components.

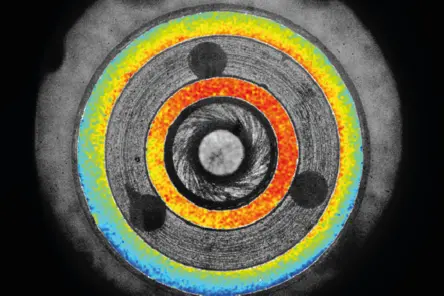

Form evaluation and flatness measurements

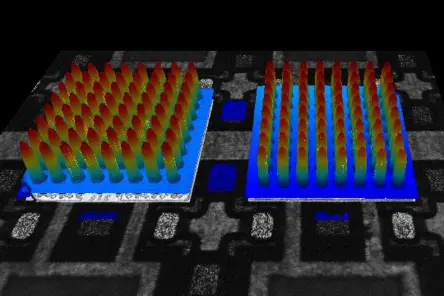

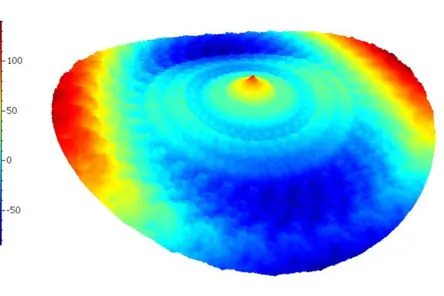

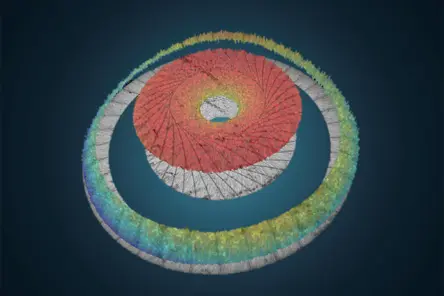

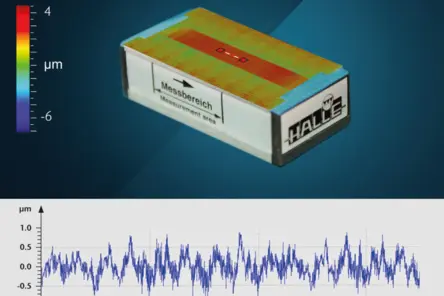

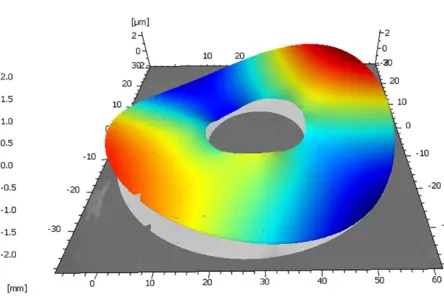

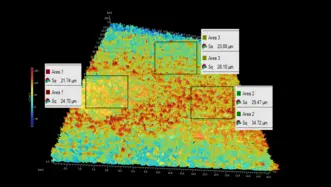

Below are real-life results from typical form and roughness measurement tasks. These examples come from our application centers, which run feasibility studies and contract measurements for customers.

Choose the right surface profiler with confidence—let us run a feasibility study with your sample.

Large-area metrology with industry-leading FoV and telecentric optics

Pro.Surf combines telecentric white-light interferometry, a large single-shot field of view ~44 × 33 mm, and a long 70 mm optical Z-range to measure flatness, parallelism and step height with high repeatability—even on large parts, trays, and deep bores.

Designed for production environments, it delivers fast, non-contact 3D topography with nm-level accuracy and automation-ready architecture.

Integrated roughness sensor (with Pro.Surf+)

→ Measure large-area form and roughness with one system

Chromatic-confocal sensor (400 µm range, ~2.6 µm lateral resolution, 10.8 mm working distance) adds roughness in the same station; typical roughness measurement Ra ≥ 100 nm.

- Combine form + roughness in one pass

- Long working distance for safe sample handling

True Stitching - Higher accuracy for wider samples

→ True Stitching provides unmatched precision when scanning wide-area samples

Because larger surfaces exceed the single-shot field of view—stitching merges tiles into one accurate dataset. The metrology quality of such large-area measurements depends on the optics and sensing technology, the number of tiles and the stitching algorithms.

True Stitching delivers high-fidelity large-area measurements by minimizing stitching artifacts and preserving geometry.

An independent benchmarking at a leading German technical university compared six optical profilers from different manufacturers and the Polytec profilometer demonstrated the highest stitching and measurement quality. This is achieved through several key features:

- Large single-shot FoV → fewer tiles and seams, less cumulative error

- Sophisticated stitching algorithms → controlled overlap, robust registration, and metrology-safe blending that preserves steps and edges

- For Pro.Surf: Telecentric/CSI optics with correlogram evaluation → stable geometry and height fidelity across tiles

The result is high-fidelity, large-area topography with fewer artifacts and audit-ready residuals—what we call True Stitching.

WLI with telecentric optical design

→ Keeps geometry accurate across height and dept

Traceably calibrated WLI/CSI delivers non-contact, areal 3D data with nanometer vertical resolution. The telecentric optical approach keeps the beams / rays parallel to the optical axis, preserving constant magnification and uniform illumination over height—even enabling measurements in holes.

- Non-contact, repeatable, fast areal scans

- Phase/envelope evaluation for smooth and rough surfaces

- Smart Scanning Technology with dynamic range handle both both rough to shiny - low to high reflecting surface areas

- Long-life 525 nm LED

Large field-of-view (FoV) optics

→ Reduces stitching and cycle time

Pro.Surf offers a wide single-shot field of view up to 44.9 × 33.8 mm (with ~1.91 million points), so broader samples or multiple parts can be measured in a single acquisition. With the built-in stitching function, coverage extends up to ~228 × 221 mm.

- Measure multiple samples at once; automatic sample recognition available

- Short cycle times; reduced stitching effort

ECT Environmental Compensation Technology

→ Stabilizes results in real shopfloor environments

Noise and ambient vibration on classic machine shops can affect precision measurements. The patented ECT Environmental Compensation Technology compensates for such disturbances, ensuring consistent data even in noisy production environments.

- Improves reliability in noisy or unstable environments

- Enables automation and inline QC without full isolation

- Especially helpful for sensitive components (e.g., MEMS, thin films)

Ready for automated metrology workflows

→ Enables unattended, repeatable measurements

The modular design and motorization options make it easy to automate and integrate the Pro.Surf profilometer into existing processes and machines. A bundle of features and capabilities enables highly efficient and unattended metrology workflows:

- Pattern matching and Smart Scanning Technologies

- Motorized X, Y, Z, tip/tilt stages

- Large FoV and automated stitching for high-resolution scans over large areas

- Recipe system in TMS (Software) for operator-independent workflows

- Rugged design without external moving parts and ECT (environmental compensation technology)

Pattern matching

Machine-vision routine that finds and registers parts against a template so recipes hit the right locations—even if parts are shifted or rotated. This reduces the costs and handling effort for fixtures and makes the measurement much easier. Ideal for trays and multi-sample runs.

SST Smart Scanning Technology

Dynamic range that adapts to varying reflectivity/contrast so you can measure “almost any surface” from matte or dark to shiny, from low to high reflecting areas in one setup in the TopMap Software.

Downloads

Feasibility check?

Send us your sample and we run a feasibility study with our profiler and walk you through the results.

This gives you a precise understanding of the optical profiler’s performance on your actual samples.

Related information and downloads

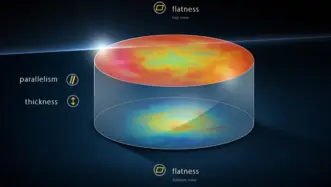

Flatness, thickness and parallelism

Flatness, thickness and parallelism (FTP) measurement combines top & bottom topography measurement in a single shot.

Surface roughness measurement

Surface texture analysis in 3D. From Sa/Sq to Str/Sal for validating specifications and surface features.

"Try before buy" offer

Measure, rent, decide - on your terms. Make a confident decision about which surface profiler fits into your metrology strategy and safeguard your capital investment.

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.