QTec® - Reinventing vibrometry

QTec® reinvents laser vibrometry by eliminating the root cause of noise delivering superior optical sensitivity, enabling high-fidelity measurements on all surfaces. In order to achieve this, QTec vibrometers use an innovative multi-path interferometer utilizing the highest quality signal of each path to reach the best results. This patented technology is combined with the well-proven infrared Xtra sensor design for faster, easier measurements and a consistent result.

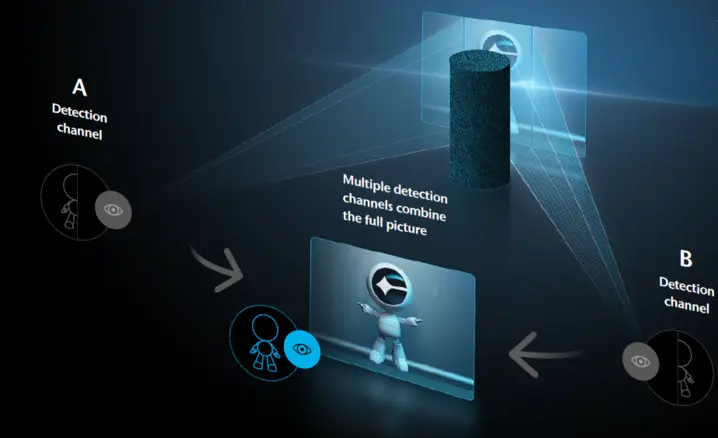

How it works - QTec® multipath interferometry

Got any questions?

Curious about how Polytec’s QTec® technology delivers precise, high-frequency vibration measurements on challenging surfaces? Explore our FAQ section to find clear answers to the most common questions – from technical principles to practical applications.

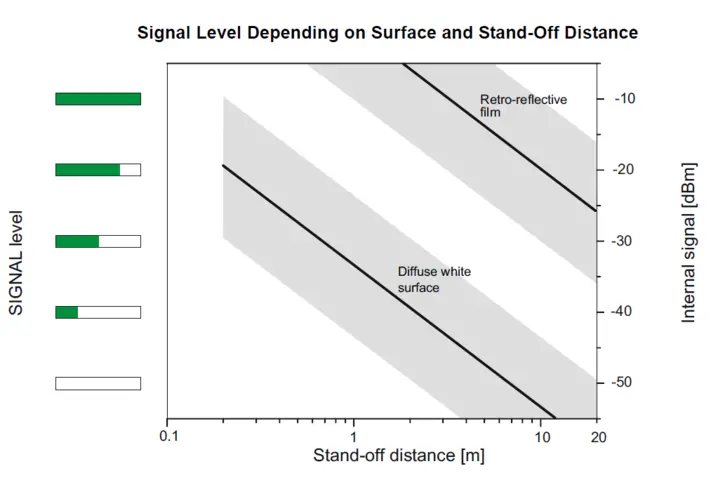

Influence of surface properties

The signal quality of a laser vibration measurement depends on the intensity of returned light. The surface determines the spatial distribution of backscattered light, and thus the information received by the photo detector from its position in space.

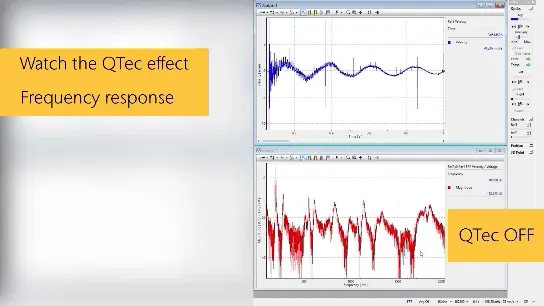

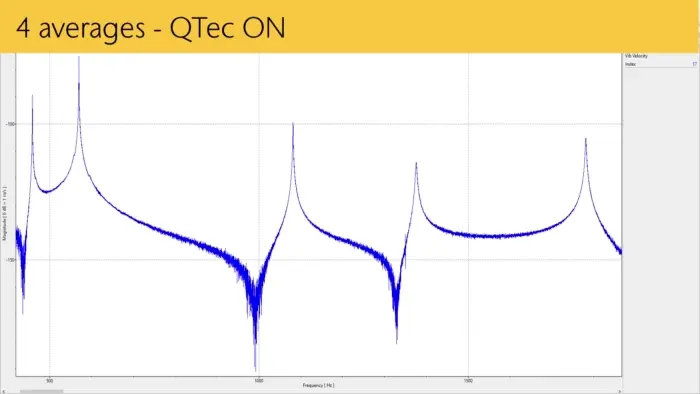

The QTec® effect

The new, patented and highly innovative technology QTec® from Polytec significantly improves the signal-to-noise ratio (SNR). QTec® resolves even the finest details in the measurement signal, facilitating a straightforward post-processing. QTec® improves the results in almost any measurement and is particularly beneficial for engineered surfaces that move laterally or rotate. The average count can be drastically reduced to achieve the same SNR and measures are independent of the surface properties.

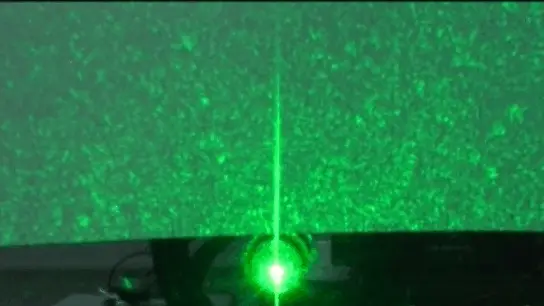

Speckle effect on engineered surfaces

On an optically smooth surface, the reflected laser light is returned without loss to the photo detector. In the real world measurements are often carried out on surfaces that are optically rough. Here the light is no more reflected but scattered containing dark and bright speckles and the laser point starts looking grainy. This pattern changes with the particular perspective of an observer. This causes changes and occasionally no light return at the photo detector. These effects can cause broadband noise and unwanted dropouts with optical measurements.

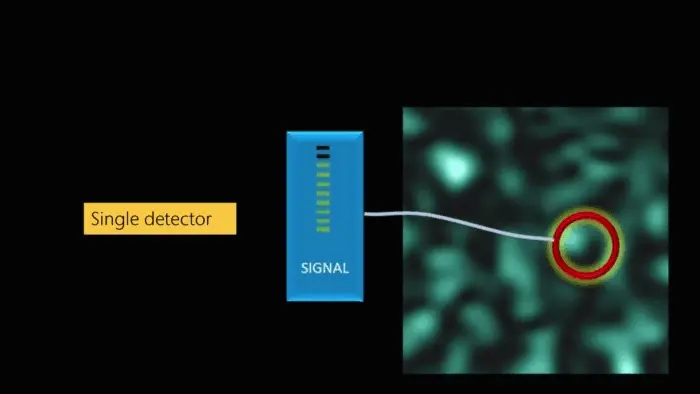

The solution: Change the perspective

The QTec® heterodyne multi-path interferometer provides exactly the capability to avoid reduced signal at the photo detector by using multiple detectors. Every detector represents an observer with a unique perspective, and thus a unique speckle pattern. As the pattern is random, it can be shown that the combination of the signals from the spatially distributed detectors results in a statistically stable signal level. The benefits of this so-called Diversity Reception apply to all engineered surfaces.

QTec® - Simplified principle of multipath laser vibrometry

Any questions about the QTec® multipath interferometry?

Ultra-fast electronics in the sensor head weight the detected signals in real-time and only the best part of the signal is transferred to a common output, making QTec® sensor heads compatible to current single channel vibrometer decoders.

The capability of QTec® to measure independently of the surface properties makes it a safe choice for all applications providing fast, easy, robust results.

Related products

VibroScan QTec Xtra

VibroScan QTec Xtra measures vibrations in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

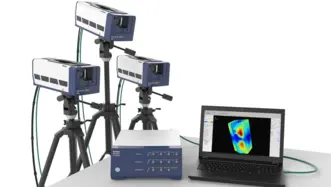

VibroScan QTec Xtra 3D

VibroScan QTec Xtra 3D measures vibrations triaxially in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra 3D ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

VibroScan QTec Neo

VibroScan QTec Neo measures vibrations in a new way - without contact, full-field and with unprecedented precision. For the first time, QTec® technology has been successfully transferred from the infrared SWIR laser to the visible helium-neon laser. Featuring a small laser measuring spot, the precise helium-neon laser is suitable for measurements on the finest structures and even measures in and through water. QTec® always ensures a stable signal and the best signal-to-noise ratio. VibroScan QTec Neo ensures maximum portability with integrated data acquisition and signal generator up to 32 MHz.

VibroFlex QTec

With the modular laser vibrometer VibroFlex, Polytec introduces the new flexibility in optical vibration measurement up to 24 MHz: Measure noise, vibration, harshness (NVH) with highest signal quality and resolution or from large and>500 m distant samples like machinery, motors etc. Choose from different sensor heads, accessories and change configurations tailored to your individual measurement task.

VibroFlex Range

VibroFlex Range is the outdoor-proof long-range vibration measurement solution designed for remote analysis of vibrating structures, model validation and health monitoring on large and distant structures from more than 500 m. The laser sensor conveniently monitors structural dynamics and stability of buildings, operating machinery and critical production facilities, providing a fast and efficient on-site testing solution.

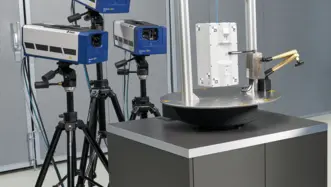

RoboVib® Bench

RoboVib® Bench enables automated and full-body experimental modal analysis using Polytec’s optical 3D scanning laser vibrometers. Its easy to set-up hardware and software integrates seamlessly into the Polytec scanning vibration measurement workflow and saves time by automatically repositioning the devices-under-test (DUT) instead of a manual and tedious relocation of the sensor setup. 360° measurements of the DUT are as easy as a measurement from just one side.

RoboVib®

By combining a 3D scanning vibrometer and an industrial robot, RoboVib® forms an automated test station for measuring everything from complex components to complete vehicle bodies. Reduce testing time and expenses as well as time to market significantly in experimental modal analysis. Conduct comprehensive 360° testing of a vehicle body, for example, within only one-two days and overnight instead of weeks of preparation with conventional test setups.