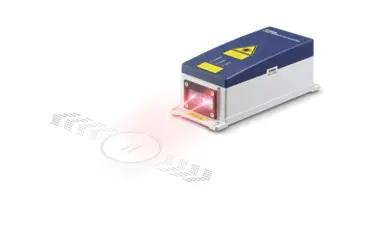

Measure speed on roll-fed material, monitor velocity on belts and piece goods

Measuring process speed inline is indispensable for reliable process control and optimization in many industrial processes. It is the basis for countless other applications such as cutting length control, length measurement, velocity difference. In these processes velocity is measured using the laser Doppler technique.

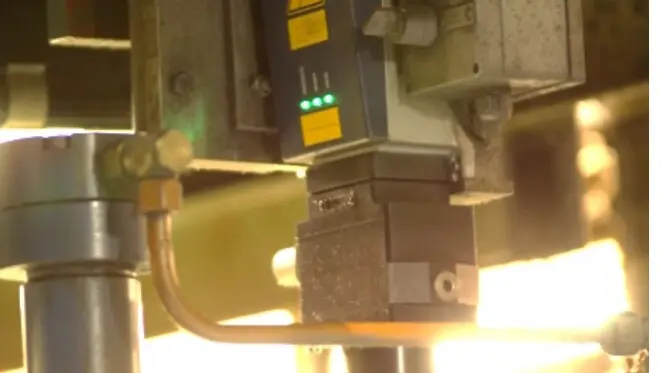

Polytec LSV Laser Surface Velocimeters are ideal process speed sensors measuring on almost any surface even on contaminated, oily surfaces, on distant or ret-hot material and in dirty, dusty production environment. The non-contact measuring technique eliminates negative influences like known from encoders regarding measurement accuracy caused by slippage and wear, plus it avoids influence on the material surface.

Measurement of process speed, differential speed and velocity synchronization on belts, sheets, piece goods

Optical sensors from Polytec are used in various industries for accurate inline speed monitoring in production processes. Whenever a manufacturer has high standards regarding dimensional accuracy, controlling the sheet or strip thickness, monitoring feed speed or synchornizing the process speed with following processes, global manufacturers rely on Polytec laser precision sensors.

- Strand length & speed measurement in continuous casting lines

- Speed monitoring in C-gauges in cold rolling, for thickness measurement and roll gap control (AGC mass flow control)

- Synchronizing cut-speed, cutting or shearing processes on sheet metals, textiles or piece goods

- Velocity synchronization e.g. for welding in tubes or pipes

- Synchronizing drive tension, or strip tension control in roll stands

- Coil synchronization in winding of cables, wires and fibers

- Determining dwell time in coating of paper or cardboards, annealing lines, thermal or finishing processes in converting

- ... (see below)

Advantages

//- Non-contact speed monitoring

- optical sensor prevents from slippage and wear

- Easy sensor integration

- into PLC with enhanced interface concept like Ethernet, fieldbuses, multi user etc.

- Compensate wavy material and altering distances

- with outstading measurement depth-of-field up to 200 mm and large stand-off-distances

- Reliable & efficient

- measurement technology enhancing process control, IP 66, 67

- Measure speed on any surface

- laser technology handles challenging materials like shiny, dusty, oily or red-hot

- Application-specific accessories

- like thermo-protective housing, air wipe and air amplifier, cooling plate, beam deflection etc.

Speed synchronization - Synchronize feed velocity

Synchronize multiple sub-processes, path sections or trigger events in your production line for an optimized flow with matching speeds: e.g. in cutting processes, winding processes, or welding tasks. Multiple LSV sensors measure the velocity or feed rate at different positions. The control system or PLC regulates drives or integrated processes based on real-time measurement data for harmonized process control.

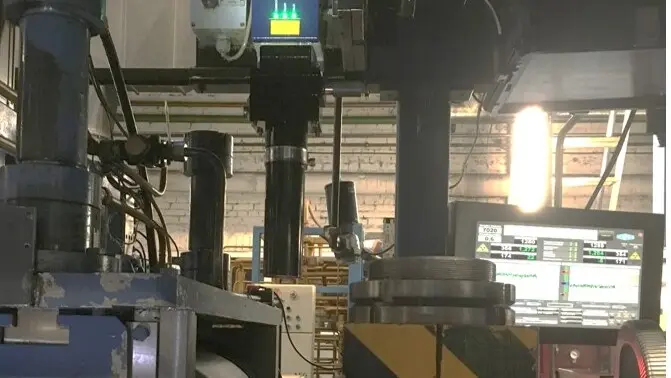

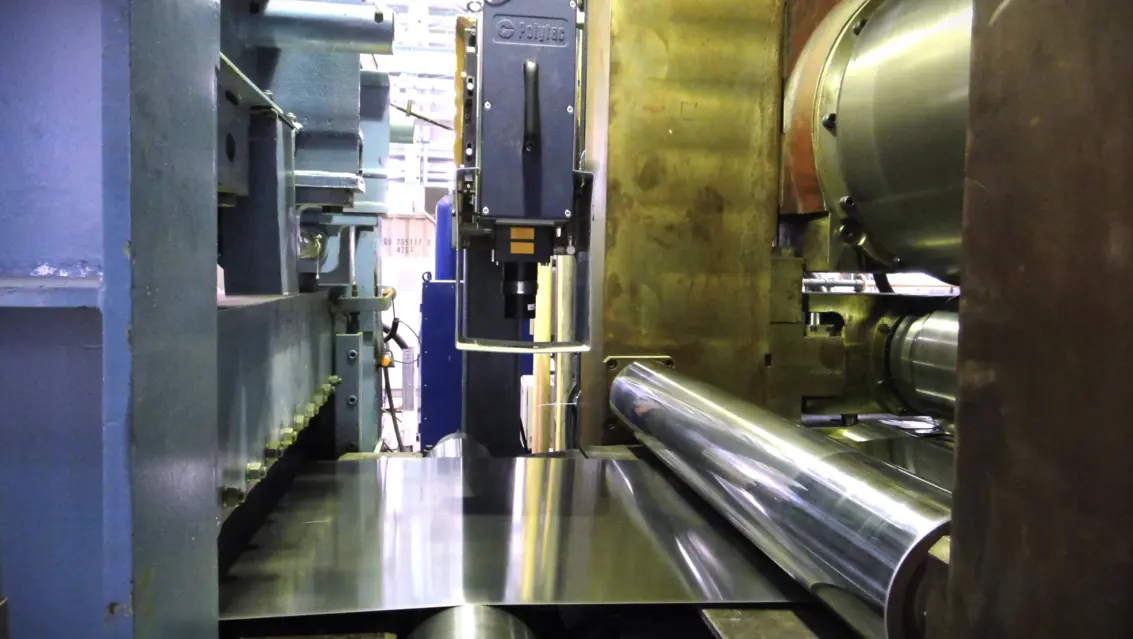

Rolling mills

E.g. in large aluminum and steel rolling plants, the length and speed of aluminum and steel strips are measured to synchronize various sections.

Cutting processes / cut to length

In the metal industry, LSV optical sensors are commonly used for synchronizing cutting devices in steel and aluminum cut-to-length processes.

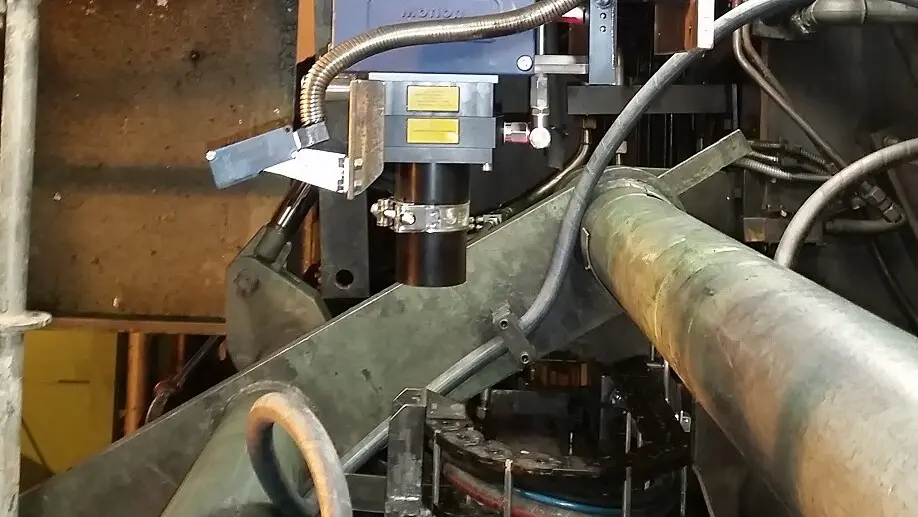

Rotary tube saws

In rolling mills for tube production, LSV sensors help synchronize the saw blades with the manufacturing line speed with laser precision, thus ensuring they rotate at the exact same speed for cut-to-length at velocities of up to 10 m/s.

Web or rolls in paper & converting

In paper production or converting processes (e.g., rolled material and sheets), optical LSVs sensors are used to guide webs synchronously, e.g., during longitudinal cutting, when winding/ unwinding web goods or transferring them from one roll to another.

"...the laser sensor pays for itself: When producing a large range of different qualities, when measuring wheels require frequent replacement. Also with special products and certain surfaces where the slip cannot be controlled, or with narrow tolerances - because when a whole batch goes out of tolerance, that’s when it gets expensive!"

Velocity difference measurement - measure differential speed

For synchronizing and harmonizing speeds rates in production lines, measure feed forward rate or line speed at two or multiple points — for example, before and after a rolling mill stand — or at different spots on a conveyor system. Polytec sensors enable differential speed measurement for controlling processes based on relative velocity, such as elongation, mass flow control, or stretching. Each LSV sensor continuously transmits real-time velocity values from its measuring position to the PLC for calculating the exact speed difference v2 – v1. This basis allows for a dynamical control of process triggers, e.g., for AGC Automatic Gauge Control (adjusting the roll gap), regulating the tension between two roles, or harmonizing the line speed.

Mass flow control in rolling mills

In single stand reversing or tandem cold rolling mills, the strip thicknesses and strip speeds are used to control the mass flow. Here, Polytec sensors provide individual speed measurements - highly accurate, without slippage and permanently calibrated. The differential speed measurement also perfectly helps regulating the material feed forward rate.

Stretch reducing mills

In skin pass or stretching mills, the elongation ("degree of stretching") is calculated by measuring the differential length between inlet and outlet tracks - practically monitored via differential speed. Skin pass degree formula (%)= ((voutlet - vinlet) / vinlet) x 100%. This allows very precise control of material elongation, e.g. for tensile strength and yield strength.

Rolling e.g. tailored blanks

In rolling mills, where strip segments with variable thicknesses are rolled, like for tailored rolled blanks, the differential speed is measured with high temporal resolution in order to precisely control the roll gap.

Paper, cardboard & packaging

LSVs measure speed differences between rolls and webs during winding and unwinding to monitor and balance tension. They are also used to synchronize individual sheets in cutting processes.

Synchronization in welding processes

In welding lines (e.g., in the metal and pipe industry), the pipe or feed speed at weld head is used for monitoring and controlling the power to weld head and for optimizing the weld power for a consistent weld quality.

Converting & textile processes

Velocity difference can become key for harmonizing individual rolls in longitudinal cutting, for matching roll and web speed in winding and unwinding processes, for tension control or in extrusion processes.

Laser precise speed monitoring in production lines - how it works

In-process velocity monitoring by industries

Talk to our experts

Free 3-year warranty on new gauges, outstanding service and reliable support: Our PolyXpert services cover from on-site support to sensor integration and commissioning, find custom solutions, calibration or repair, and an uncompromising sensor exchange program. With Polytec, you invest in a reliable partnership, know-how and trust!