No budget? Just measure.

Whether you need contract measurements, equipment rental, or leasing, our scalable services deliver precise data—without the overhead of major investments. Ideal for short-term projects, occasional use, or limited budgets.

With PolyFlex you get results without compromising timelines or budgets.

Engineering service and measurement equipment rental

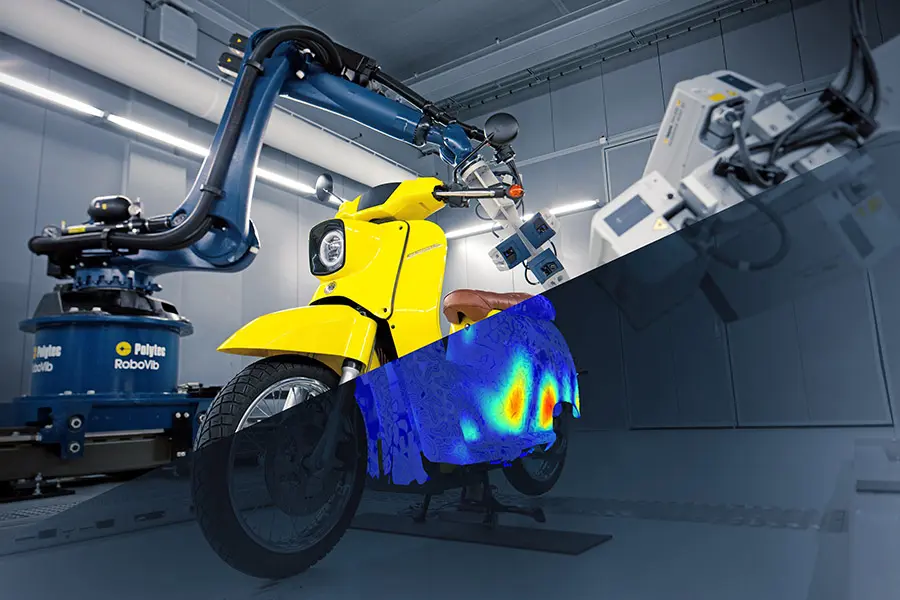

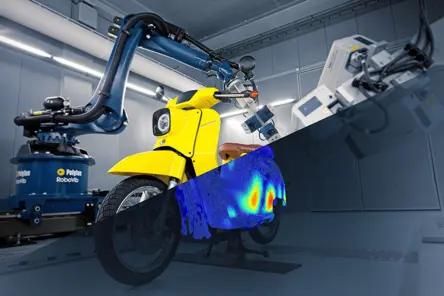

Outsource your measurement tasks simply to Polytec or rent our cutting edge measurement instruments. Expect quick and reliable measurement reports from our PolyXperts as basis for further decisions and improvements while cutting down your cost of ownership, especially for non-frequent testing needs. Use our modern measurement labs including our RoboVib® structural test station. Our experienced engineers support you through every phase needed, including consulting of test setups at your site.

All of our labs are set up for video conferencing for remote testing services allowing you to send in parts and join without the need for travel.

Vibration measurement and rental as a service

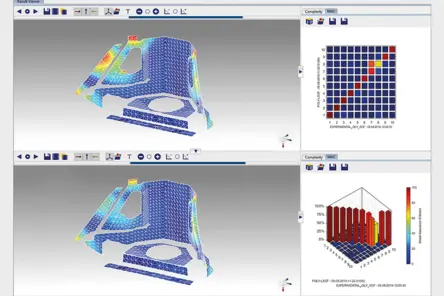

- Get high quality experimental modal data as animated deflection shapes in 3D together with corresponding frequency response functions for a detailed correlation with your FE models.

- Detailed operational deflection shape data resolved in frequency or time for evaluating vibration behavior under operational conditions

- Data for NVH analysis (noise, vibration, harshness) to optimize acoustics and analyze the effect of vibration on comfort or durability.

- Non-contact and full-field strain measurement for high cycle fatigue (HCF) testing typically for turbine blades or bladed disks (blisks)

- Simultaneous measurement of relative movements during transients events like shock or noise profiles, e.g for EV and HEV batteries

- Non-destructive testing (NDT), locating defects in composite samples without contact using lamb waves, local defect resonance or mode shape deviation techniques

- Sound pressure fields can be measured and visualized without influence on the field

- Measurement data for design verification of MEMS and micro-acoustic components, vibration frequencies up to 8 GHz

- NEW: High-fidelity testing of encapsulated microsystem devices by measuring the MEMS through the silicon cap with our innovative IRIS technology.

Get in touch with our experts

Get in touch with our experts

Let’s talk! We will find the right solution for your needs.

Highlights

- Benefit from the latest optical measurement technology

- Video conferencing allows remote testing services

- Highest cost-efficiency at zero cost of ownership with rentals and services

- Get high quality data as reliable base for further development

- Non-contact sensor technology reveals true vibrational behavior, dynamics and acoustics

- Use external expertise and support to expand your capacities

Automated experimental modal analysis as measurement service

Downloads

Related products

RoboVib®

By combining a 3D scanning vibrometer and an industrial robot, RoboVib® forms an automated test station for measuring everything from complex components to complete vehicle bodies. Reduce testing time and expenses as well as time to market significantly in experimental modal analysis. Conduct comprehensive 360° testing of a vehicle body, for example, within only one-two days and overnight instead of weeks of preparation with conventional test setups.

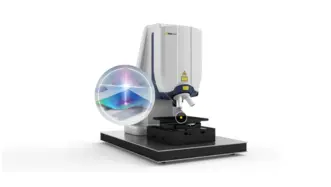

MSA-600 Micro System Analyzer

The all-in-one optical measurement solution for static and dynamic 3D characterization of MEMS and microstructures- now for up to 8 GHz! The MSA-600 enhances microsystem development and quality inspections - also allowing testing on wafer-level when integrated into commercially available probe stations.

MSA IRIS measurement service

This brand new, patented measurement technology allows for comprehensive and representative analysis of Si encapsulated MEMS, measuring dynamics right through silicon caps. Our PolyXperts are looking forward to receiving your capped MEMS samples for modal testing, feasibility studies and consulting throughout all phases from development over prototyping to manufacturing of your encapsulated microstructures.