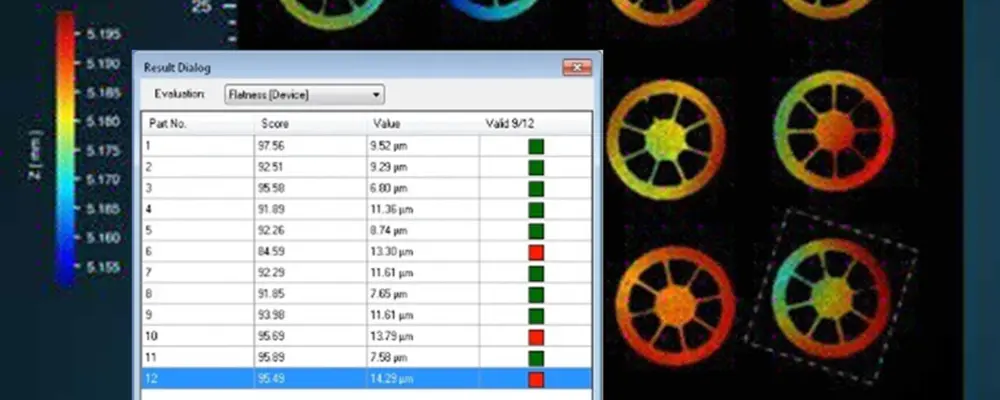

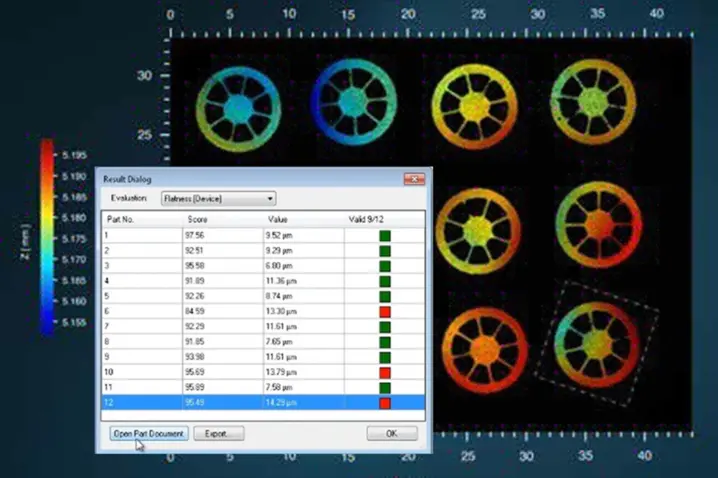

Reliable pass-fail analysis in-line or at-line

Modern production measuring technology ensures that these limits are complied with at all times. After all, you will only continuously achieve high product quality if you use precise instruments.

Optical surface measurement systems that can be integrated in the production line as in-line applications detect defective parts within the process. These results enable you to take precautions that adjust production operations in good time. Reliable pass/ fail decisions in production lines increase efficiency and keep your reputation high.

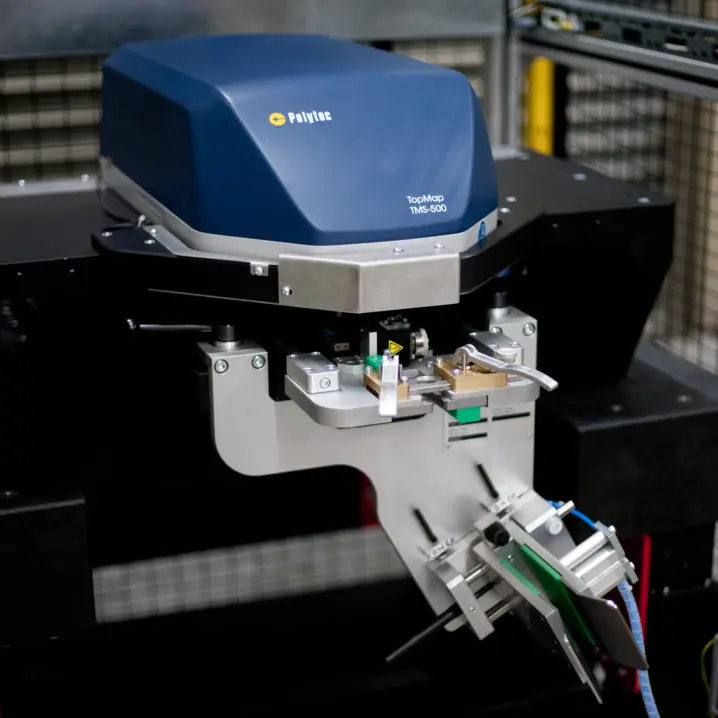

Polytec's white-light interferometers allow you to contactlessly examine both structures and surfaces in the blink of an eye. In many cases, an object’s entire topography needs to be checked prior to certification. Polytec TopMap surface measuring systems increase testing efficiency due to its large areal measurements.

Optical profilometers with widest field of view (FoV)

For Pass/Fail measurement, the Pro.Surf series is the most efficient surface profilometer with an unmatched flexibility regarding material, size and complexity of samples.

Convince yourself what Pro.Surf can do for you by having an online demo or directly rent a system.

Surface particle detection for precision components

Another pass/fail analysis is the surface inspection for high-precision components. With specific surface features and characteristics, a metrology analysis can be a mandatory step to reduce non-conformance cost.

For such surface inspection we recommend to either utilize Pro.Surf+ with the mounted roughness sensor or a Micro.View profiler.

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.