VibroScan QTec

New VibroScan QTec product line released, the next milestone in data quality, productivity and application flexibility

Full-field vibrometers

Full-field vibrometers measure the areal and complex vibrational behavior in a non-contact and non-destructive way based on the laser Doppler principle. Vibrometers from Polytec are established RnD tools that significantly shorten development times by providing comprehensive and precise insights into acoustics and dynamics of vibrating structures. The meaningful visualization of Eigenmodes and operating deflection shapes based on high fidelity data will take your FE model validation to the next level. All full-field vibrometers are turnkey solutions with diverse upgrade options, comprising sensor head, data acquisition and analysis software. As your requirements grow, you can upgrade and expand Polytec vibrometers step-by-step up to fully automized testing solutions from DC to the Megahertz range. Polytec is pioneering advanced technologies like infrared (SWIR) lasers, FPGA-based digital decoding, patented multi-path interferometry QTec® for providing best performance in non-contact vibration testing.

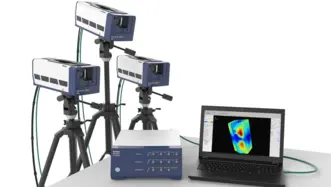

VibroScan QTec Xtra

VibroScan QTec Xtra measures vibrations in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

VibroScan QTec Xtra 3D

VibroScan QTec Xtra 3D measures vibrations triaxially in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra 3D ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

VibroScan QTec Neo

VibroScan QTec Neo measures vibrations in a new way - without contact, full-field and with unprecedented precision. For the first time, QTec® technology has been successfully transferred from the infrared SWIR laser to the visible helium-neon laser. Featuring a small laser measuring spot, the precise helium-neon laser is suitable for measurements on the finest structures and even measures in and through water. QTec® always ensures a stable signal and the best signal-to-noise ratio. VibroScan QTec Neo ensures maximum portability with integrated data acquisition and signal generator up to 32 MHz.

No budget? Just measure.

Whether you need contract measurements, equipment rental, or leasing, our scalable services deliver precise data—without the overhead of major investments. Ideal for short-term projects, occasional use, or limited budgets.

With PolyFlex you get results without compromising timelines or budgets.

Extensions and accessories

Create a solution that meets your specific needs by enabling your system with even more capabilities.

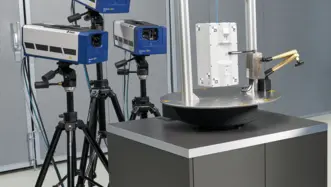

RoboVib® Bench

RoboVib® Bench enables automated and full-body experimental modal analysis using Polytec’s optical 3D scanning laser vibrometers. Its easy to set-up hardware and software integrates seamlessly into the Polytec scanning vibration measurement workflow and saves time by automatically repositioning the devices-under-test (DUT) instead of a manual and tedious relocation of the sensor setup. 360° measurements of the DUT are as easy as a measurement from just one side.

RoboVib®

By combining a 3D scanning vibrometer and an industrial robot, RoboVib® forms an automated test station for measuring everything from complex components to complete vehicle bodies. Reduce testing time and expenses as well as time to market significantly in experimental modal analysis. Conduct comprehensive 360° testing of a vehicle body, for example, within only one-two days and overnight instead of weeks of preparation with conventional test setups.

PSV-A-440 Optical Derotator

The PSV-A-440 Optical Derotator enables non-contact vibration measurements on rotating parts with PSV Scanning Vibrometers. Fully characterize dynamics of rotating objects such as fans for consumer products and vehicles or turbines under operational conditions up to 24,000 RPM.