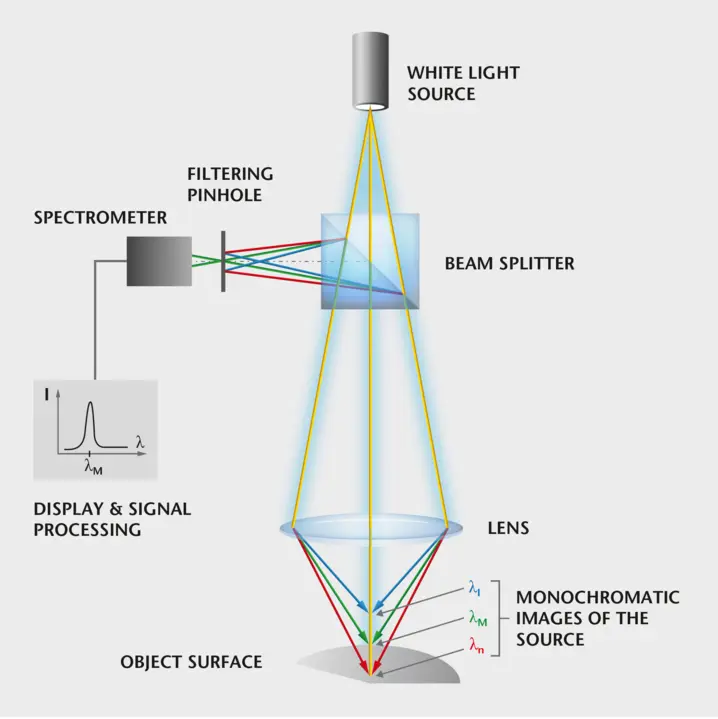

The chromatic-confocal measurement principle

Chromatic confocal method for optical measurement technology for measuring distance and thickness has been established as one of the mature methods available to industry and research. Incident white light is imaged through a chromatic lens to yield a continuum of monochromatic light along the z-axis, thereby “color coding” the optical axis. When an object is present in this color field, a single wavelength is fixed to its surface and then reflected back to the optical system. The backscattered beam passes through a filtering pinhole and is then acquired by a spectrometer. The beam’s specific wavelength is calculated to precisely determine the position of the surface in the measurement field. Chromatic confocal technology allows reliable, accurate and reproducible dimensional measurements with high resolution.

Find out more about the strengths and limitations of the different and common surface measurement methods in the technology comparison, regarding vertical and lateral resolution, application sweet spots on smooth surfaces or roughness measurement, with or w/o stitching.

- White-light interferometry

- Confocal microscopy

- Focus variation

- Chromatic confocal sensors

Take a look at our wide range of WLI profilers

Micro Profiler

Micro.View profiler systems are optimized for measurements with sub-nanometer resolution. With focused optics and high vertical resolution they enable detailed analysis of microstructures, surface finish and material distribution where even the smallest deviations matter.

Macro Profiler

Pro.Surf with its areal topography scanning determines form and flatness faster. Its telecentric optics with large Z range reaches holes and recessed surfaces. The largest FoV and True Stitching handles big samples and multi-sample measurements with ease. Upgrade to Pro.Surf+ and also analyze roughness all-in-one.

Metro.Lab

Metro.Lab is a compact, wide-area surface profiler. It combines high measurement performance with a small footprint—ideal for space or budget conscious applications that still require reliable 3D surface data.

Choose the right surface profiler with confidence—benefit from our "try before buy" approach.

Related stories and downloads

Interview with Prof. Dr. Albert Weckenmann about optical and tactile surface measurement technology

We talked with Prof. Dr. Albert Weckenmann of the University of Erlangen-Nuremberg, Germany, about the limitations of tactile surface measurement technology and the opportunities of non-contact methods.

Overview of optical methods for surface metrology

For applications where tactile surface measurement techniques have shortcomings, non-contact optical instruments have been developed to overcome these shortcomings. Especially with the development of compu…

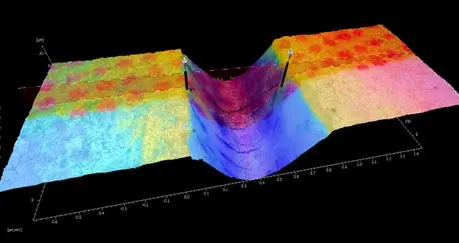

How CSI technology retrieves superior topography, form & roughness measurement data

Read how the optical technology of Coherence Scanning Interferometry (CSI) analyzes topography, form & roughness, where are sweet-spots, benefits and applications compared to related optical surface inspec…

Downloads

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.