Roughness parameters translate texture into functional requirements: sealing performance, imaging quality in optics, noise and friction in mechanics, coating adhesion, and display haptics. To ensure a unified understanding in global supply chains, such parameters are defined in standards as Ra/Rz (profile) and Sa/Sq (areal).

Surface topography and its structural details like surface roughness is traditionally inspected using tactile stylus-based profilometers (stylus instruments) by guiding a probe tip over a workpiece surface and detecting each vertical deflection by the surface texture. With this method, the information about the surface topography including surface details like roughness is obtained along a 2D profile.

Due to increasing quality and process demands, the single profile-based information was not sufficient and an "areal" analysis of surfaces was requested - which lead to optical surface profilers.

Optical vs tactile surface roughness and texture evaluation

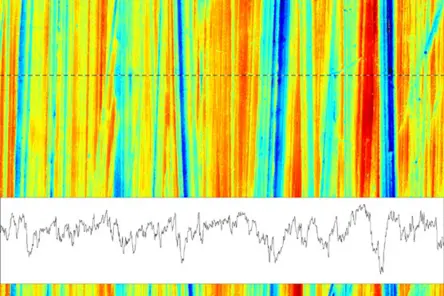

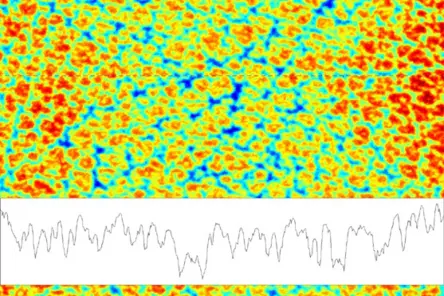

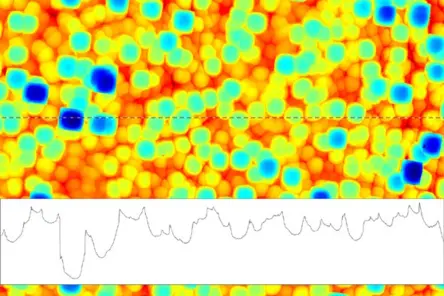

If the surface has randomly distributed features, the result for the roughness parameter is strongly influenced by the measuring position. In many cases, profile-based surface description is insufficient to provide information about functional behavior of the surface.

Profile based surface characterization allows only limited information about the cause of poor functionality and so includes limited information for quality control purposes.

How to quickly measure surface roughness in 3D

This video shows how to measure and characterize surface roughness on mechanical engineered components, e.g. polished surfaces using non-contact optical surface profilers like the TopMap whitelight-interferometers.

Choose your magnification, benefit from motorized turret and the automatic Focus Finder for areal 3D roughness measurement and evaluation. Manage and load your individual and predefined measurement recipes for simplified quick starts of 3D roughness evaluation and easily report and share your insights on roughness evaluation e.g. according to ISO 25178 and more.

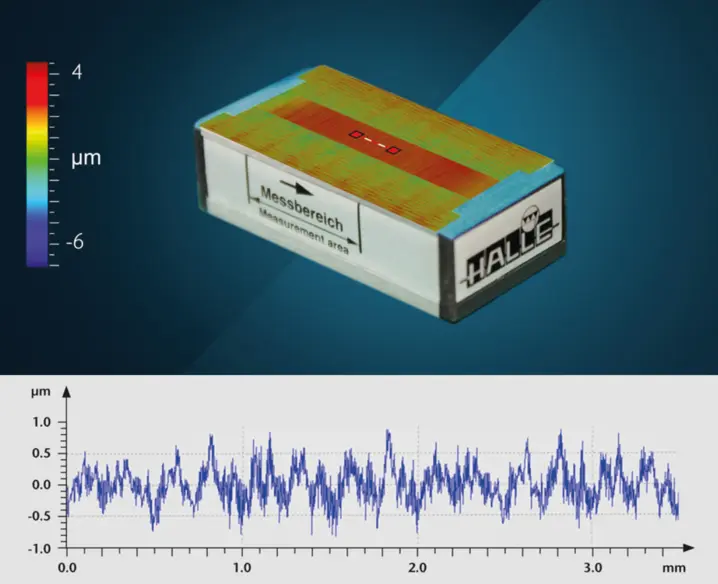

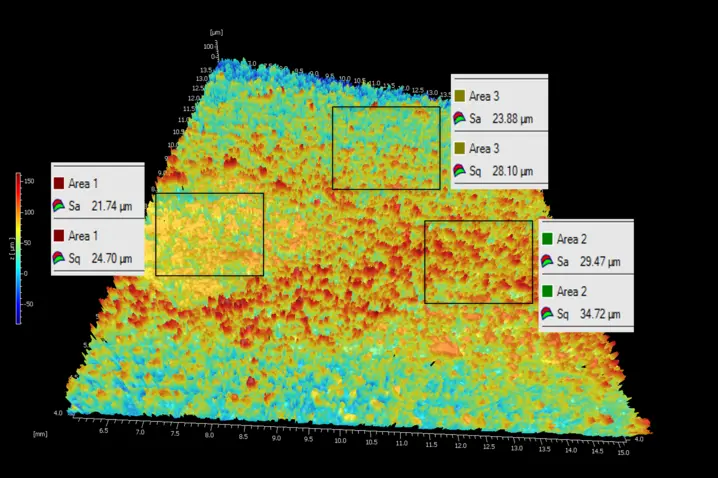

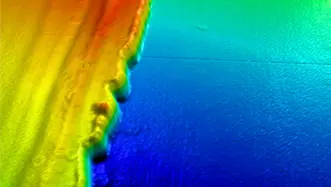

Areal 3D surface roughness measurement data

Three-dimensional, areal topography measurement is not subjected to those limitations. Not only does it provide an image of the surface that makes it easier to understand, but areal measurements also enable a function- and structure-oriented evaluation.

Furthermore, 2D profiles can easily be extracted from the areal measurement data which can again be evaluated according to the common rules of profile-based roughness evaluation. In contrast to a tactile roughness measurement, optical 3D roughness measurement is non-contact and non-reactive thus avoiding any damage or influence on sensitive surfaces by the measurement procedure.

ISO for profile and areal surface evaluation

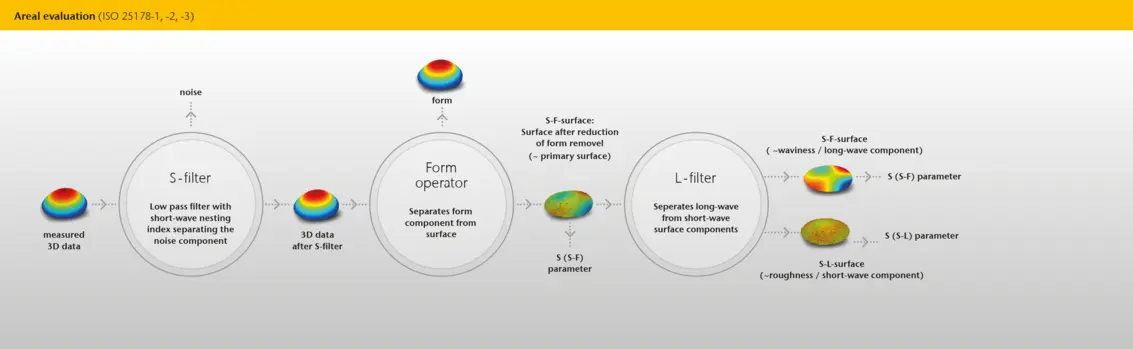

The measurement chains for the areal or profile-based surface evaluation are described in ISO 25178 or ISO 4287, they differ from each other with some details.

Download the whitepaper for surface roughness evaluation

Optical profilometers are increasingly replacing tactile measuring systems. Eventually in the near future, 2D parameters will only endure where their informative value is sufficient.

A comprehensive and full 3D characterization of the entire sample surface e.g. by using optical surface metrology like TopMap whitelight intefereometers offers an intuitive visualization of measurement data while permiting extensive evaluation options for a deeper analysis and feedback on the production process.

Sign up and read in the full paper about surface roughness and how to measure surfaces faster and more efficient.

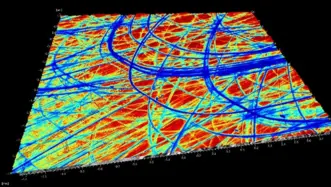

Optical scanning of 3D textures

White-light profilometers or coherence scanning interferometers are optical surface profilers, providing a non-contact measurement approach, reliably capturing 3D surface topography data without physically touching the surface. They are excellent for measuring 3D surface roughness parameters and texture, such as Sa and Sq, as well as for capturing detailed surface structures and shapes.

Optical profilers are non-destructive and suitable for all sorts of surfaces including fragile or delicate ones. They are also faster for measuring larger surface areas. However, optical profilers may have limitations on shiny and bent surfaces. In summary, the choice between optical and tactile surface profiling methods depends on the specific application, the type of surface being measured, the required accuracy, and other factors. Both methods have their advantages and limitations.

Your WLI options for measuring surface roughness

Micro.View

TopMap Micro.View® is an easy to use optical profiler in a compact table-top setup. Choose Micro.View® as the cost-effective inspection tool for examining precision-engineered surfaces down to the sub-nm range, for inspecting roughness, microstructures and more surface details.

Micro.View+

Advanced microscope-based surface profiler with automation and color imaging. Micro.View+ enables repeatable, operator-independent roughness and texture analysis—ready for lab and production use.

Pro.Surf+

Multi-sensor optical profiler combining large-area form measurement with integrated roughness analysis. Pro.Surf+ delivers fast, traceable form and roughness results in one production-ready system.

Choose the right surface profiler with confidence—benefit from our "try before buy" approach.

Further surface parameters

Surface texture

Surface texture defines a material's topography regarding roughness, waviness & lay.

Surface flatness measurement

Measure surface flatness and characterize workpiece topography regarding surface flatness tolerances according to ISO 1101, ISO 12781

Surface step height

Profilometric step-height measurement delivers objective layer/etch depth and uniformity from areal data, supporting ISO-aligned reporting and production SPC.

Layer thickness

Measure areal surfaces parameters to control layer thickness and optimize coating processes for minimizing quality costs.

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.