Inspecting form and surface quality in ultra-precision machining

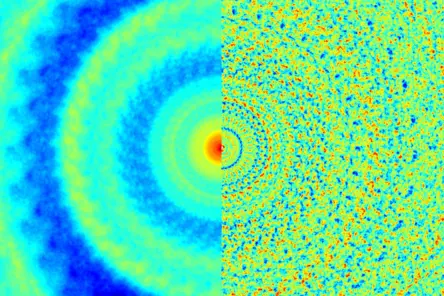

Ultra-precision machining places extreme demands on surface quality and form accuracy. Sub-micron deviations and nanometer-scale roughness have a direct impact on functionality, reliability and lifetime.

Polytec optical 3D surface metrology enables non-contact, areal inspection of form, roughness and microstructure — from diamond turning to grinding, lapping and polishing. Reproducible measurement data provide clear process feedback and support stable, high-quality manufacturing.

- Macro-Systems with telecentric optics for faster form measurements with large FOV,

- Microscopic profilers with focused optics for more structural details with sub-nm resolution!

Areal surface analysis is key to UPM quality

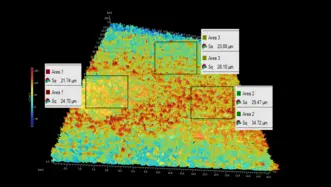

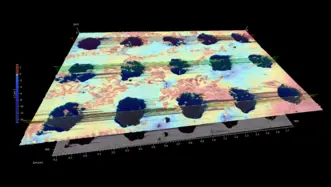

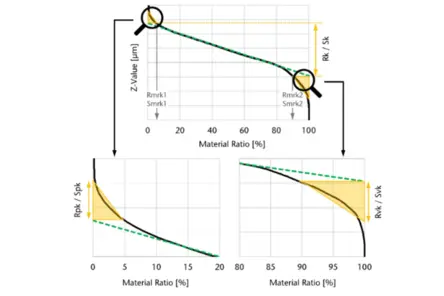

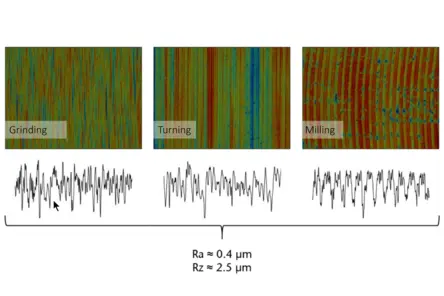

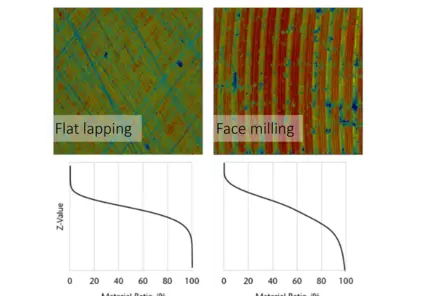

The functional performance of ultra-precision machined surfaces cannot be fully described by conventional roughness parameters alone. Only an areal analysis of the material distribution provides reliable insight into load-bearing behavior, contact mechanics and tribological performance.

TopMap optical 3D surface profilers capture surface topography areally and with high resolution – both in the lab and close to production. From this data, material ratio curves (Abbott–Firestone curves) are derived, enabling a differentiated evaluation of surface structure beyond Ra or Rz values.

In many UPM applications – such as diamond turning, ultra-precision grinding or polishing – friction and contact behavior can be deliberately influenced by controlling particle distribution, size and shape. A defined material distribution helps reduce unwanted relative motion, minimize wear and increase functional reliability.

TopMap 3D profilers provide the metrological basis for this approach: reproducible, standards-oriented and suitable for closed-loop process feedback in ultra-precision manufacturing.

Optical profilers for form, roughness and functional surface inspection

Micro Profiler

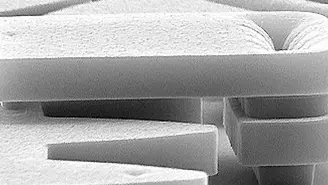

Micro.View profiler systems are optimized for measurements with sub-nanometer resolution. With focused optics and high vertical resolution they enable detailed analysis of microstructures, surface finish and material distribution where even the smallest deviations matter.

Macro Profiler

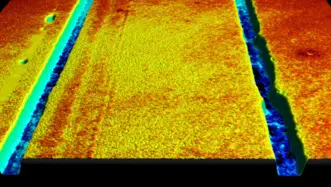

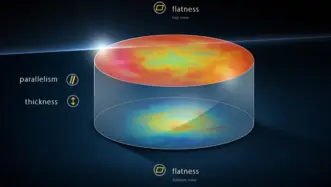

Pro.Surf with its areal topography scanning determines form and flatness faster. Its telecentric optics with large Z range reaches holes and recessed surfaces. The largest FoV and True Stitching handles big samples and multi-sample measurements with ease. Upgrade to Pro.Surf+ and also analyze roughness all-in-one.

Metro.Lab

Metro.Lab is a compact, wide-area surface profiler. It combines high measurement performance with a small footprint—ideal for space or budget conscious applications that still require reliable 3D surface data.

Choose the right surface profiler with confidence—benefit from our "try before buy" approach.

High precision manufacturing examples

Watchmaking

Fast, high-res 3D surface measurements for micro parts in watchmaking & precision mechanics – e.g. minute wheels, data disks. Contact Polytec.

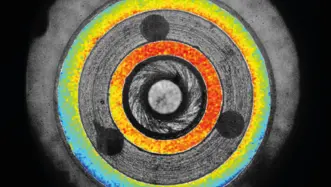

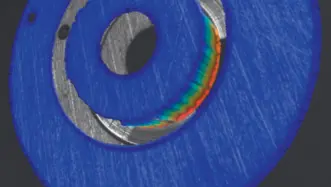

Sealing surfaces

The quality of sealing surfaces has a decisive influence on connections not being ‘leaky’. Prevent this risk with surface measurement systems from Polytec.

Fuel injection systems

Tight tolerances are a must for the energy efficiency of injection systems. The use of precise surface measurement ensures reliable and high quality.

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.