Unlock your potential in performance and quality

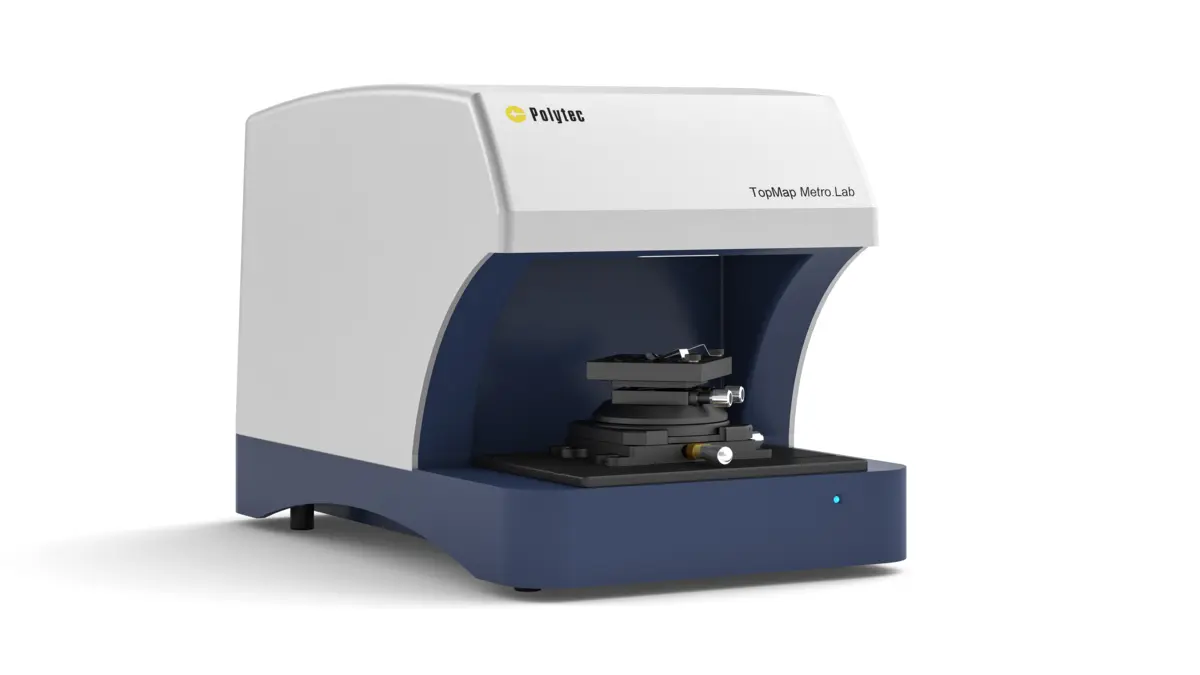

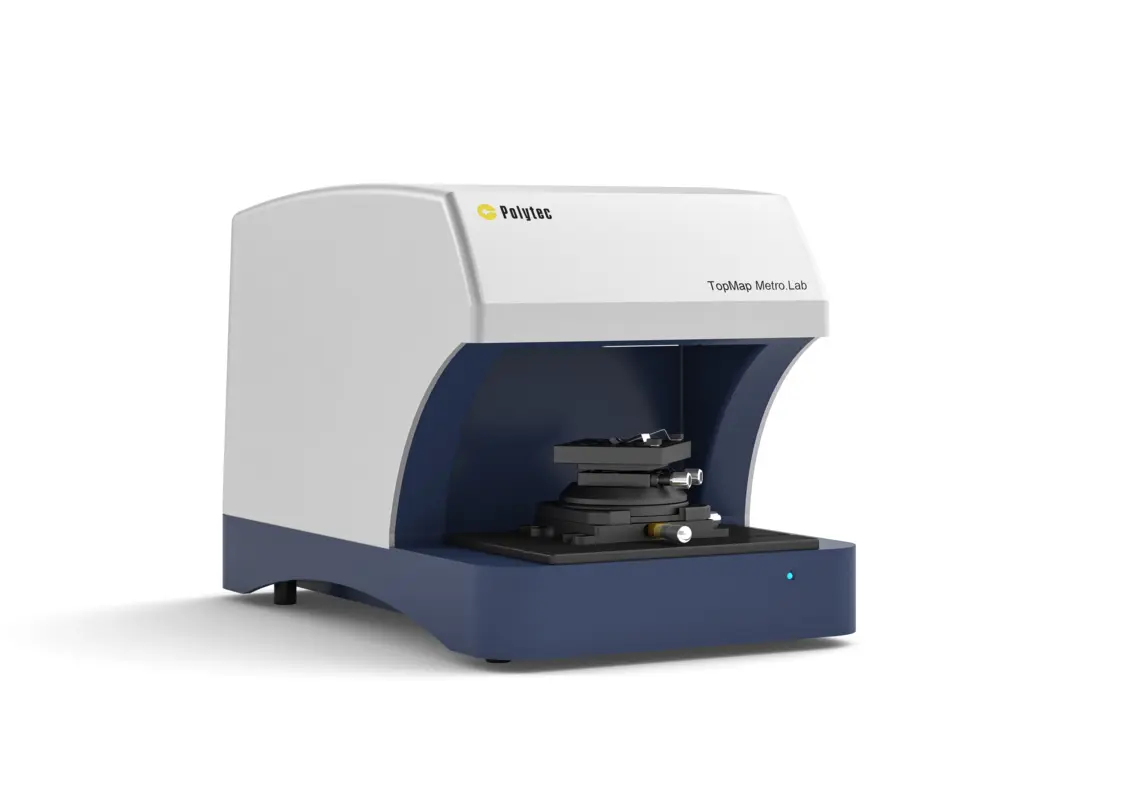

The Metro.Lab white-light interferometer is our compact entry-level system for measuring flatness, step height and parallelism on components with an area of up to 87 × 78 mm. Thanks to its non-contact measurement principle, it is also suitable for soft and sensitive surfaces.

The telecentric optics with constant magnification across the entire field of view enable a large working distance and even measurements inside bores.

The recipe-driven software supports repeatable quality assurance routines as well as automated report generation – making the system an ideal partner for part inspection in production.

Optical bench profiler for efficient quality inspection

Fast pass fail decision with large FoV

Seize a large single field of view 37 × 28 mm (~1.24 Mpts) for mid- to large sized sampels in a single shot. With extended lateral coverage up to 87 × 78 mm it even allows for multi-sample measurements and quick pass/fail checks. In vertical (Z Axis), the specimen height can range from 0 to 70 mm.

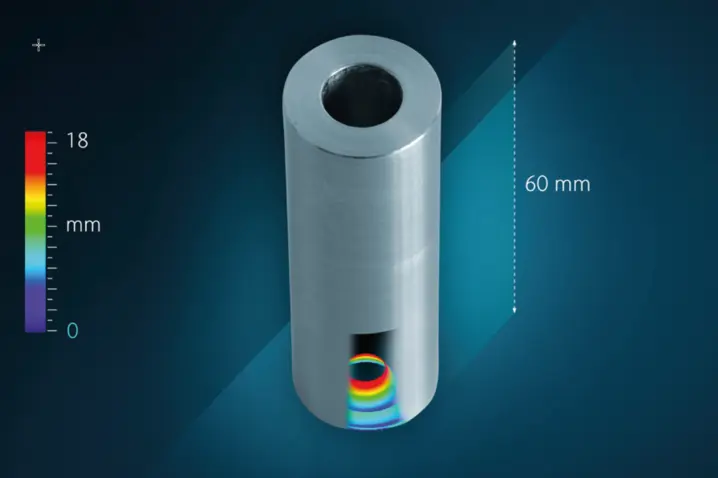

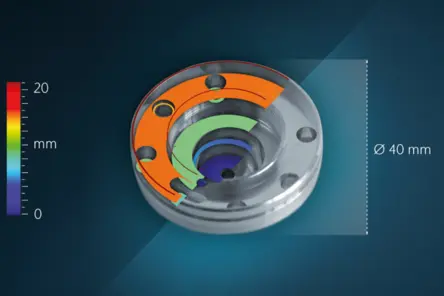

Measuring deep and hard-to-reach surfaces

With the telecentric optics and a large z scan range, Metro.Lab reaches deep holes, bores or recessed areas while keeping a safe gap to the part and thus avoiding collision.

This is particularly helpful on macroscopic components with bores or recesses where conventional optics face shadowing effects.

Accuracy you need with a reproducibility you can trust

A 70 mm vertical measuring range handles large steps and form deviations, while nanometer-scale performance supports tight tolerances: <2.85 nm vertical resolution (phase evaluation).

The rugged design without moving parts demonstrates a low measurement noise and high repeatability. In addition a vibration damping system is integrated to rougher environments.

ISO compliant recipes and documentation

TopMap profilers support recipe-based measurements for recurring inspections and testing routines. Barcode scanners load predefined settings and evluations. The software automatically recognizes lay and form of your sample type avoiding any need for mechanical fixture. Operators start ISO compliant and reproducible measurements with just one click without further training.

Evaluations follow DIN/ISO standards (e.g. ISO 25178). Results are visualized with clear pass/fail, and reports can be archived or exported to QS-STAT™ for SPC—supporting efficiency, repeatability, and traceability in lab or production.

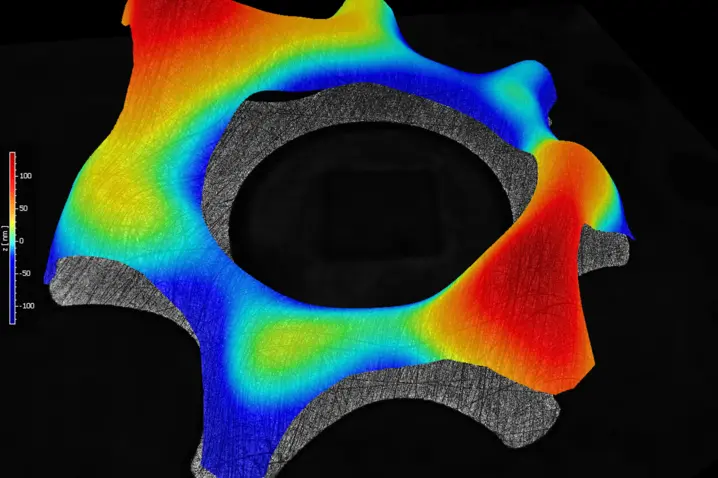

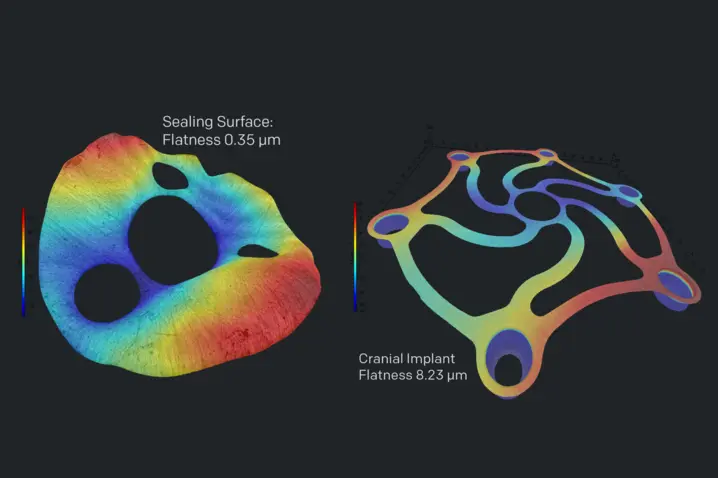

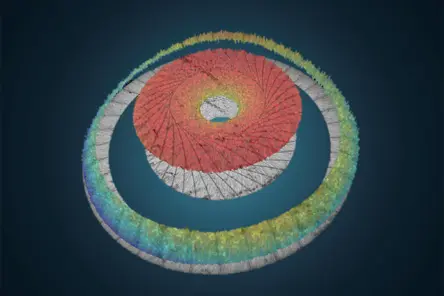

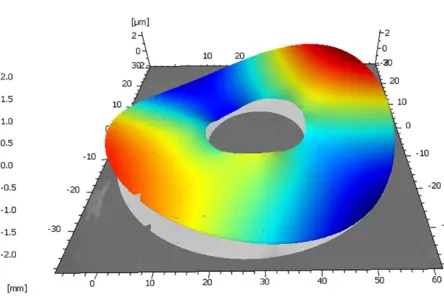

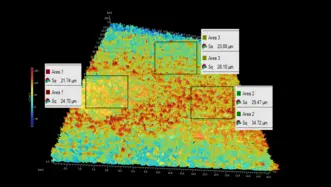

Metrology tasks and visualizations

Below or some real-life results from standard tasks across common engineering materials. Those examples are gathered by our application centers which does feasibility studies and offers contractual measurement services.

Choose the right surface profiler with confidence—get a demonstration of our capabilities.

Compact 3D profilometer with wide Field-of-View (FoV)

The Metro.Lab platform combines large-area optics, long Z-range and ISO-aligned software for precise, repeatable measurements — even on recessed or delicate features.

- Broad Field of View (37 × 28 mm with True Stitching 87 × 78 mm) enable batch or large sample analysis

- Telecentric lens enables measurement of bores, holes and recessed areas

- 70 mm large Z range with nm resolution

- Predefined recipes and barcode scanner for routine inspections at production level

Telecentric optics

Captures even recessed areas for measureming in holes without shadowing effects.

Smart Scanning Technology

SST supports measurement of reflective or matte surfaces

Integrated vibration damping

for rugged measurements in rougher surroundings.

Large Field-of-View (FoV)

Single measuring field of 37x28 mm. With True Stitching up to 87 x 78 mm.

Sample positioning

Automated pattern recogniction allow multi-sample measurements, stitching expands FoV to 87 x 78 mm.

Flexible vertical range

For specimen heights from 0 to 70 mm

Compact system

with small footprint for table or bench placement

The Metro.Lab capabilities in numbers

| Vertical range | 70mm |

| Vertical resolution | 2.83 nm |

| Field of view (FoV) | 37 x 28 mm |

| FoV with True Stitching | 87 x 78 mm |

| XY pixels | 1,284 x 966 |

| Digital XY sampling | 29.3 µm |

Downloads

Need more speed and FoV? Pro.Surf is your option.

Both Metro.Lab and Pro.Surf are macroscopic, telecentric WLI/CSI profilers with a 70 mm Z measuring range. The Pro.Surf line may be a better choice in case of:

- Bigger samples

- Faster inspections of batches or higher throughput

- Higher resolution and highest repeatability

- Production integration or inline measurements

Related information and downloads

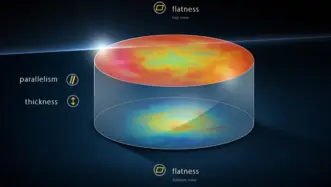

Flatness, thickness and parallelism

Flatness, thickness and parallelism (FTP) measurement combines top & bottom topography measurement in a single shot.

Surface roughness measurement

Surface texture analysis in 3D. From Sa/Sq to Str/Sal for validating specifications and surface features.

"Try before buy" offer

Measure, rent, decide - on your terms. Make a confident decision about which surface profiler fits into your metrology strategy and safeguard your capital investment.

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.