Watchmakers rely on CSI Coherence Scanning Interferometry

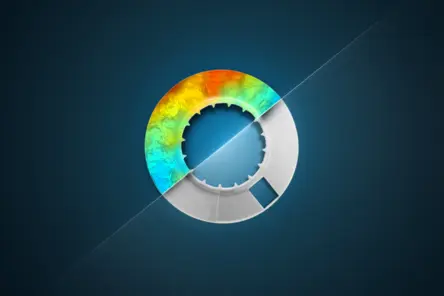

The surface quality of watch and clock parts depends on measurement precision and repeatability of CSI Coherence Scanning Interferometers (also known as white.light interferometers). Check geometrical tolerances on watch components, measuring form parameters like flatness, parallelism or step-height in watchmaking.

TopMap areal scanning white-light-interferometers deliver fast, complete and high resolution measurement data on micro parts. In contrast to other optical measurement technologies (fringe projection or focus variation), TopMap optical profilers measure reliably on both rough and optically smooth surfaces!

Flatness, thickness and parallelism of watch components

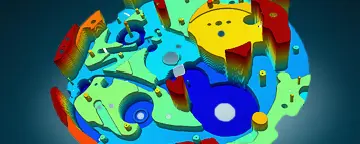

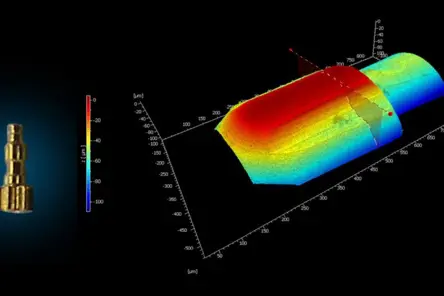

Let's take a closer look over a watchmaker’s shoulder to see, how white-light interferometers supports their precision engineered surfaces. Evaluate steps, flatness and parallelism on adjacent surfaces on watch parts and other precision engineered parts. A minute wheel drive from a watch shown as 3D topography profile. To verify the manufactured quality, the surface roughness on the inclined area, which is about 100 x 300 μm2 must be measured. Tactile measurement methods would cause problems due to the geometry of the measurement area. On the other hand, optical techniques such as white-light interferometry allow the topography to be captured within a matter of seconds.

For the innovative combined measurement approach of flatness, thickness and parallelism all together, read more about this dedicated precision mechanics inspection solution or contact us.

Fitting surface profiler

Micro Profiler

Micro.View profiler systems are optimized for measurements with sub-nanometer resolution. With focused optics and high vertical resolution they enable detailed analysis of microstructures, surface finish and material distribution where even the smallest deviations matter.

Macro Profiler

Pro.Surf with its areal topography scanning determines form and flatness faster. Its telecentric optics with large Z range reaches holes and recessed surfaces. The largest FoV and True Stitching handles big samples and multi-sample measurements with ease. Upgrade to Pro.Surf+ and also analyze roughness all-in-one.

Metro.Lab

Metro.Lab is a compact, wide-area surface profiler. It combines high measurement performance with a small footprint—ideal for space or budget conscious applications that still require reliable 3D surface data.

Choose the right surface profiler with confidence—benefit from our "try before buy" approach.

Related applications and measurement tasks

Ultra precision machining

Surface metrology for precision and ultraprecision mechanics, form precision measurement in µm, areal roughness accuracy in (sub)nanometer range.

Form deviation & roughness

Characterize entire workpiece surfaces, calculate volume and exactly determine peaks and valleys on behalf of the examined distance parameters.

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.