Keeping tolerances tight in injection systems

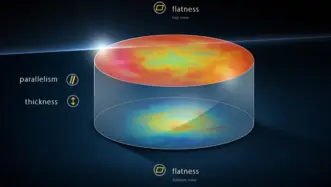

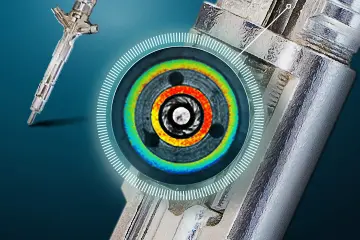

Maximum precision and compliance with the tightest tolerances are essential for ensuring the energy efficiency of subcomponents and the injection system as a whole. To achieve this, it is necessary to determine not only surfaces' roughness, but also form deviation, using high-precision instruments with a view to controlling a reliable and high-quality manufacturing process. And what should you use to complete these measuring tasks?

The surface measurement systems from Polytec are based on the principle of white-light interferometry and achieve extremely high nanometer resolution. They make “in-line” surface characterization - in other words, performing measurements during production - quick and easy for you. The results you achieve in doing so are traceable and comply with both national and international standards.

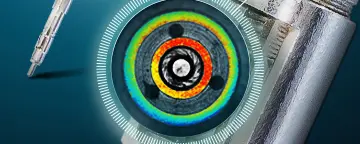

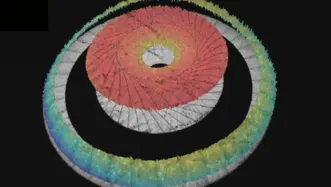

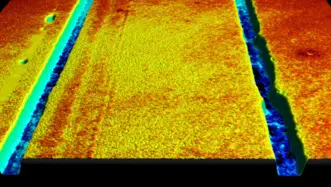

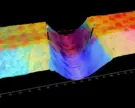

Inspecting roughness and flatness on sealing surfaces

The demands placed on modern fuel injection systems in the automotive industry are very high to ensure that fuel can combust in an ever cleaner and more efficient way. To meet these increased expectations made of the injection process, the individual components’ surfaces must be manufactured with very tight tolerances. This is a task where Polytec surface measurement systems really do play to their strengths.

Fitting optical profilers for fuel injection systems

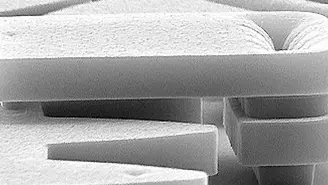

Micro Profiler

Micro.View profiler systems are optimized for measurements with sub-nanometer resolution. With focused optics and high vertical resolution they enable detailed analysis of microstructures, surface finish and material distribution where even the smallest deviations matter.

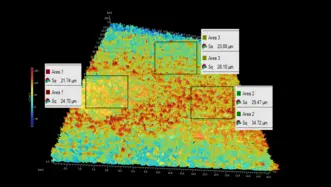

Macro Profiler

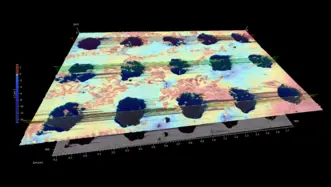

Pro.Surf with its areal topography scanning determines form and flatness faster. Its telecentric optics with large Z range reaches holes and recessed surfaces. The largest FoV and True Stitching handles big samples and multi-sample measurements with ease. Upgrade to Pro.Surf+ and also analyze roughness all-in-one.

Metro.Lab

Metro.Lab is a compact, wide-area surface profiler. It combines high measurement performance with a small footprint—ideal for space or budget conscious applications that still require reliable 3D surface data.

Choose the right surface profiler with confidence—benefit from our "try before buy" approach.

Further metrology applications

Stories & Downloads

Downloads

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.