Characterizing microsystems' and MEMS' topography and dynamics

Using the versatile surface measurement systems from Polytec, you can complete your micro and nano technology tasks reliably, quickly and with a high level of precision. You can eject channel depths on your lab-on-a-chip, determine the step height on MEMS packaging, establish how flat pressure sensors are and analyze MEMS using surface parameters. Even performing dynamic out-of-plane and in-plane measurements on RF filters to determine MHz resonance frequencies will be a simple task for you now – thanks to Polytec’s MSA Micro System Analyzer series.

Optical profilers and vibrometers for micro- and nanotechnology

Macro Profiler

Pro.Surf with its areal topography scanning determines form and flatness faster. Its telecentric optics with large Z range reaches holes and recessed surfaces. The largest FoV and True Stitching handles big samples and multi-sample measurements with ease. Upgrade to Pro.Surf+ and also analyze roughness all-in-one.

Micro Profiler

Micro.View profiler systems are optimized for measurements with sub-nanometer resolution. With focused optics and high vertical resolution they enable detailed analysis of microstructures, surface finish and material distribution where even the smallest deviations matter.

Microscope-based vibrometers

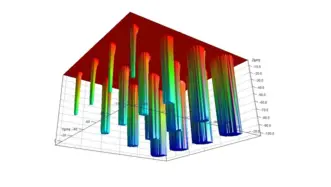

Inspired by the rapid further development of microelectromechanical systems and MEMS, Polytec presents this highly innovative product line of microscope-based measurement systems. MSA Micr System Analyzers from Polytec validate dynamics and topography of microsystems reliably with utmost precision.

Related measurement tasks

Coatings and layer thickness

Coating quality control in 3D. Assessing pre-coat texture, post-coat defects, and film thickness.

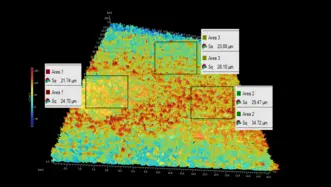

Surface roughness measurement

Surface texture analysis in 3D. From Sa/Sq to Str/Sal for validating specifications and surface features.

Surface metrology on microstructures

Topography & dynamics of microstructures and for nanotech. 3D geometry, roughness, and time-resolved motion.

Related applications

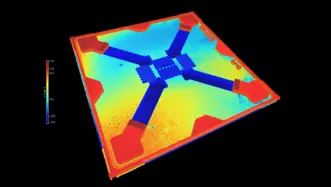

MEMS pressure sensor

Surface characterization of MEMS pressure sensors for optimal quality & production control. Explore more about measuring MEMS pressure sensors.

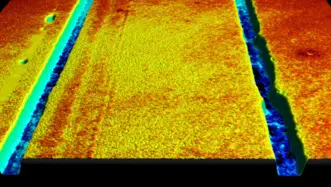

Vertical interconnect access (VIA)

Reliable quality inspections: check etching depths in automated processes, measure distances and surface parameters on Vertical interconnect accesses.

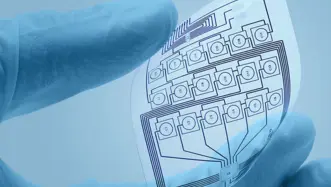

Flexible electronics

Polytec optical systems ensure process control and tolerance checks in printed and in-foil hybrid electronics with integrated chips

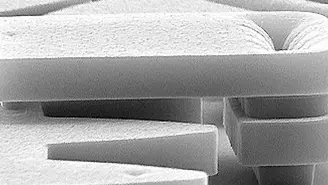

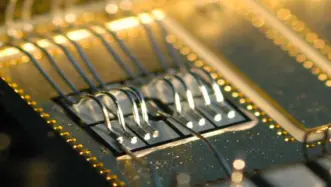

Die bonding

In epoxy die bonding, the accurate placement & attachment of the die is crucial for quality. Ask for TopMap surface metrology for die bonding process control.

Lab-on-a-chip

Test your lab-on-a-chip devices (LoC) using 3D measurement data evaluating form parameters for quality control: channel depth, step height and flatness.

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.