Surface inspection on drive technology with nm precision

Technical surfaces with purposefully created microstructures and nanostructures are key to reducing wear and energy consumption. Manufacturers only stand a chance of improving their products if they use faster, more reliable measuring technology that is repeatable at any time.

Polytec's surface measurement systems allow you to record 3D structures quickly and extensively. You can use special Polytec products within the production line too. Polytec will see you right – even if you need to perform measurements in holes up to 70mm deep.

Surface profiler with widest field of view (FoV)

For measuring components, the Pro.Surf series offers the most efficient optical profilometer with an unmatched flexibility in regard to material, size and complexity of samples.

Convince yourself what Pro.Surf can do for you, by having an online demo or directly rent a system.

Relevant surface measurement tasks

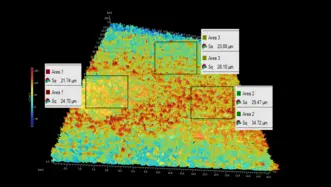

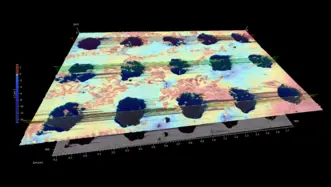

Surface roughness measurement

Surface texture analysis in 3D. From Sa/Sq to Str/Sal for validating specifications and surface features.

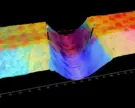

Maintain form and position tolerances

Verify form and position tolerances such as waviness, flatness, parallelism and tilt. Optical 3D surface metrology delivers reliable results—even in bores.

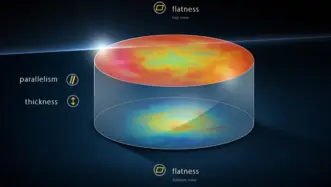

Flatness, thickness and parallelism

Flatness, thickness and parallelism (FTP) measurement combines top & bottom topography measurement in a single shot.

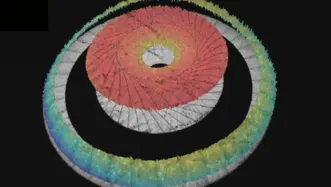

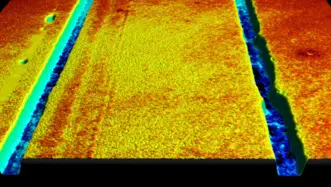

Coatings and layer thickness

Coating quality control in 3D. Assessing pre-coat texture, post-coat defects, and film thickness.

Tribology analysis

Tribology analysis with 3D surface profiler. Inspecting friction, wear and lubrication performance.

Pass/fail analysis

WLIs deliver fast, objective and easy-to-use pass/fail feedback from areal 3D data. Sub-nanometer Z resolution and recipe-driven workflows support inline SPC.

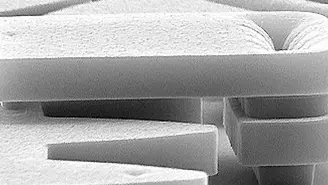

Surface metrology on microstructures

Topography & dynamics of microstructures and for nanotech. 3D geometry, roughness, and time-resolved motion.

Further metrology applications

Stories & Downloads

Downloads

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.