Quality inspection on precision mechanics

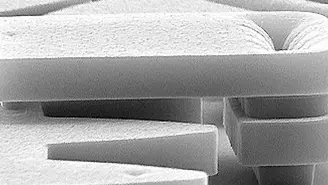

Both the surface quality of compensating discs and the pistons are crucial in shock absorber development if a quality product is to be created. That’s because pistons and compensating discs are key components for correct shock absorber function. They control how a shock is absorbed, since they act like a valve for the liquid or gas inside. Form deviations outside of defined tolerances at moving parts’ contact points may lead to leakage.

Precise control and monitoring in the manufacturing process is essential if the targeted absorption effect is to be guaranteed. Both of these tasks are simply inconceivable without production measuring technology. Tactile surface metrology methods used to detect these shortcomings are very time-consuming and only provide an illustration for part of the surface.

Areal surface characterization in a single shot

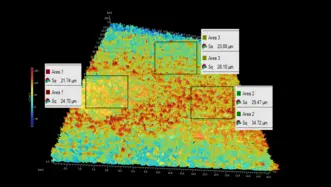

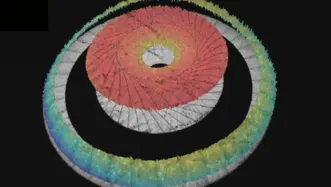

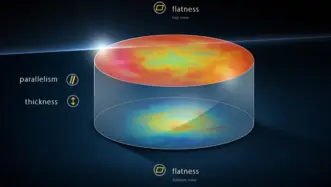

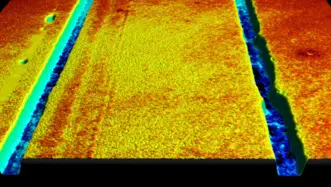

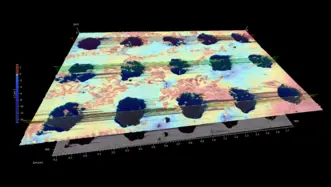

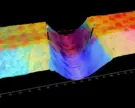

TopMap optical surface metrology from Polytec not only saves time, but also provides detailed 3D measurement data of entire surfaces, and particularly of such high-performance components’ critical parameters – such as flatness, parallelism and step height.

Capturing all surface details in a single measurement, evaluating parameters like flatness, step height and parallelism on a shock absorber piston

Surface profiler with widest field of view (FoV)

For measuring components, the Pro.Surf series offers the most efficient surface profilometer with an unmatched flexibility in regard to material, size and complexity of samples.

Convince yourself what Pro.Surf can do for you, by having an online demo or directly rent a system

Further metrology applications

Stories & Downloads

Downloads

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.