表面測量任務

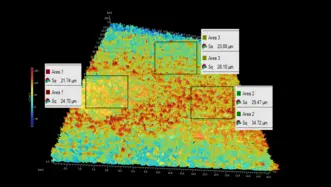

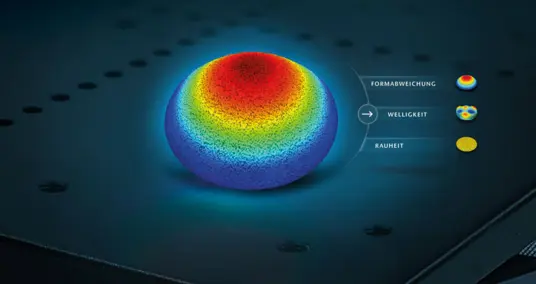

功能性與流程要求透過標準化表面參數來表達,這些參數能量化地形與紋理特性。以下彙編詳述各項參數、評估建議方法及相容的測量系統。

表面粗糙度測量

三維表面紋理分析參數。從Sa/Sq到Str/Sal,用於驗證規格與表面特徵。

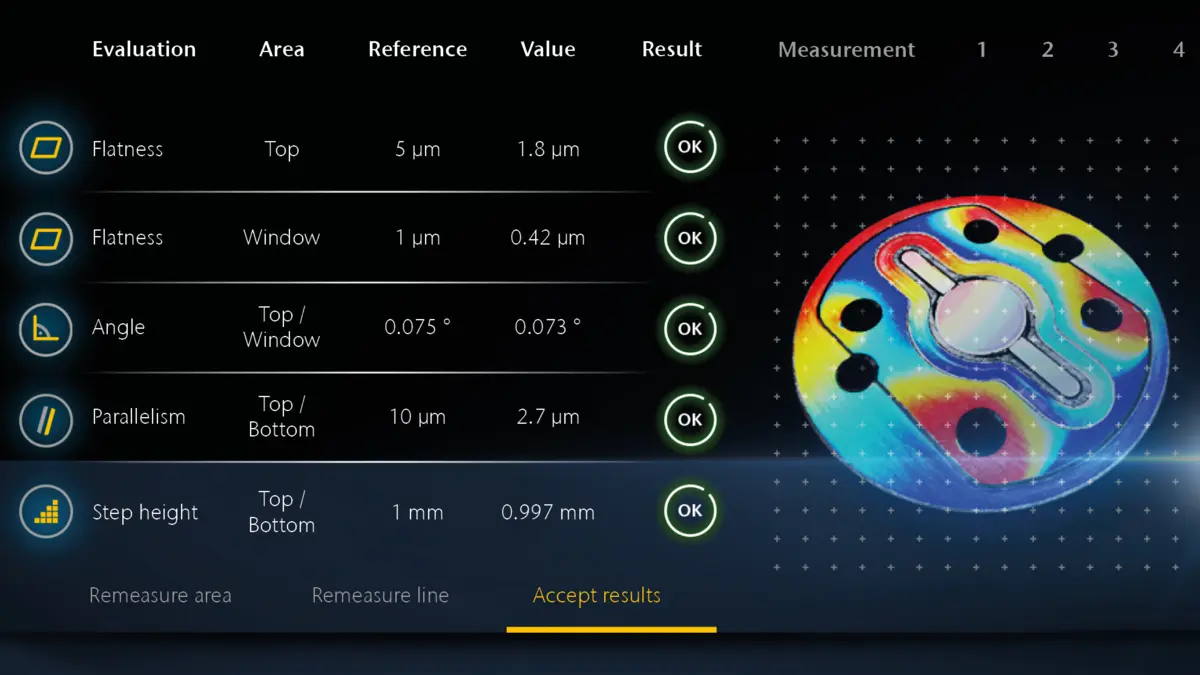

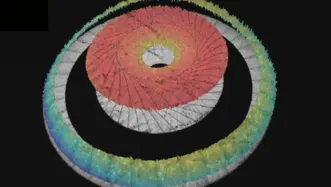

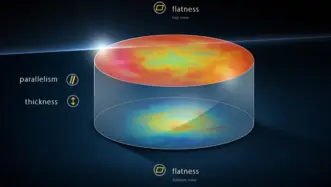

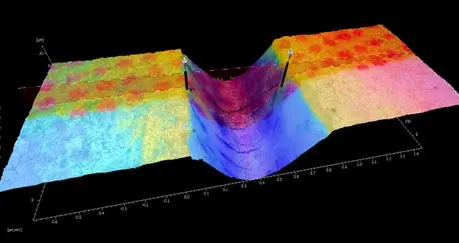

Maintain form and position tolerances

Verify form and position tolerances such as waviness, flatness, parallelism and tilt. Optical 3D surface metrology delivers reliable results—even in bores.

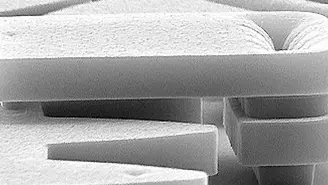

微結構表面測量技術

微結構與納米技術的地形學與動力學。三維幾何結構、粗糙度與時間解析運動。

平整度、厚度與平行度

平面度、厚度與平行度(FTP)測量技術,可於單次操作中同步完成頂部與底部的表面形貌測量。

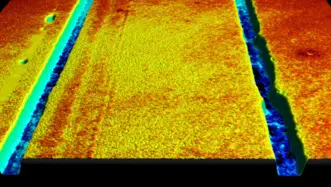

塗層與層厚

三維塗層品質控制。評估預塗層紋理、後塗層缺陷及薄膜厚度

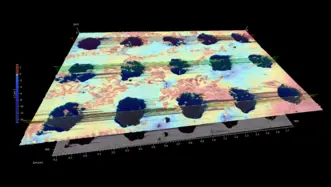

摩擦學分析

採用三維表面輪廓儀進行摩擦學分析。評估摩擦、磨損及潤滑性能。

合格/不合格分析

WLIs 提供快速、客觀且易於使用的區域性 3D 資料合格/不合格反饋。亞奈米級 Z 軸與配方驅動的工作流程支援線上 SPC。

各行業中的表面測量技術

不同產業基於功能、可靠性與合規性需求,對表面特性提出各異的規範要求。以下頁面統整常見應用領域與零件類型、典型參數目標值,以及相應的量測方法與系統方案。

各類工作區域的表面解決方案

量測系統的需求因環境與工作職能而異。製造業著重於產能與操作便利性;大學、研發機構及品質實驗室則要求靈活性與精確度。

作品集——從宏觀到微觀的地形學

微型分析儀

Micro.View systems are optimized for ultra-high-resolution measurements in the sub-nanometer range. With focused optics and high vertical resolution they enable detailed analysis of microstructures, surface finish and material distribution where even the smallest deviations matter.

巨觀分析器

Pro.Surf凭借其区域地形扫描技术,能更快地确定形状与平整度。其大Z轴范围的同轴光学系统可探测孔洞与凹陷表面,最大视场与真实拼接功能轻松应对大型样品及多样品测量。升级至Pro.Surf+,更可实现粗糙度分析一体化操作。

Metro.Lab

Metro.Lab是一款紧凑型广域表面轮廓仪。它将卓越的测量性能与小巧的占地面积完美结合,特别适用于空间或预算受限但仍需可靠3D表面数据的应用场景。

選擇合適的表面處理方案,請放心選用轮廓仪 ——透過我們的「先試用後購買」方案,讓您輕鬆獲益。

相關文章與故事

相干扫描干涉测量技术(CSI)

了解相干掃描干涉儀(CSI)的光學技術如何分析地形、形狀與粗糙度,並與相關光學表面檢測方法相比,其優勢所在、最佳應用點及實際應用範疇。

Characterizing surface texture, roughness, imperfections and scratches

Optical polishing is a fabrication technique developed specifically to achieve minimal defects and smooth micro-roughness values. Polishing is a process that involves the use of free grains, usually suspen…

Interview with Prof. Dr. Albert Weckenmann about optical and tactile surface measurement technology

We talked with Prof. Dr. Albert Weckenmann of the University of Erlangen-Nuremberg, Germany, about the limitations of tactile surface measurement technology and the opportunities of non-contact methods.

Confirm flatness, roughness and step height – TopMap quality control on the factory floor

Consistently producing high-quality precision parts is better achieved when the supporting metrology is tightly integrated with the manufacturing process. By combining Polytec’s TopMap optical metrology wi…

Overview of optical methods for surface metrology

For applications where tactile surface measurement techniques have shortcomings, non-contact optical instruments have been developed to overcome these shortcomings. Especially with the development of compu…

How surface metrology reveals the finest forensic details

Forensic science plays a vital role in the criminal justice system by providing scientifically based information through the analysis of physical evidence. During an investigation, evidence is collected at…