Form and position tolerances in precision components

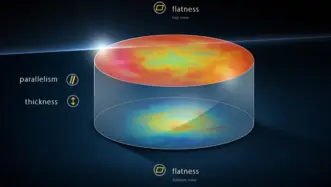

When manufacturing components, increasingly tight production tolerances must be met — particularly on technical and functional precision surfaces. Manufacturers therefore need to verify form tolerances such as waviness or flatness, as well as position tolerances such as parallelism and tilt, with high accuracy. This ensures compliance with specifications and reliable delivery within defined timeframes.

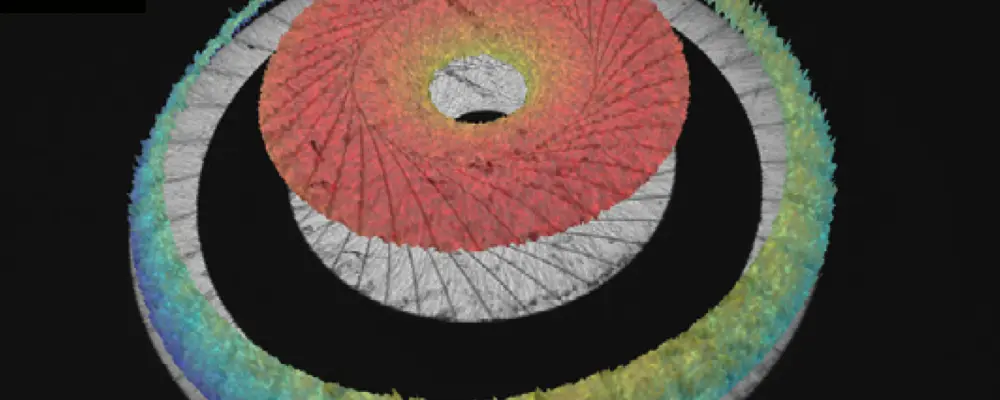

In many cases, manufacturers inspect the complete surface topography of a component to verify compliance with form and position tolerances — for example in shock absorber components, other precision parts in the automotive and aerospace industries, or in fine mechanics.

Verifying form and position tolerances

White-light interferometry measure form parameters such as flatness, parallelism and step-height faster and more efficient even with large samples. Working great on materials of different reflectivity, such as shiny polished metals, or dull ceramics makes them the flexible choice for lab and production. Requirements for component warpage (e.g., printed circuit boards) also continue to increase as geometries shrink.

In addition, many applications involve challenging geometries: areas of interest may be located inside deep bores or show significant height differences between functional areas. Here, Polytec systems based on proven white-light interferometry deliver reliable results — where other optical measurement methods face limitations.

Polytec white-light interferometers perform repeatable, non-destructive measurements with resolutions of only a few nanometers — and even sub-nanometer capability. Optical profilers are ideally suited for the precise determination of form parameters such as flatness and parallelism — supporting efficient verification and easy integration into inline inspection workflows for form and position tolerances.

Optical profilers for tolerance verification

Polytec provides optical systems for measuring the topography of large surfaces with nanometer-level vertical resolution. This high vertical resolution is independent of the field of view, enabling stable measurement results across different sample sizes and inspection setups. Typical measurement tasks include determining flatness, step height, roughness, parallelism, and other surface parameters required to comply with form and position tolerances.

微型分析儀

Micro.View systems are optimized for ultra-high-resolution measurements in the sub-nanometer range. With focused optics and high vertical resolution they enable detailed analysis of microstructures, surface finish and material distribution where even the smallest deviations matter.

巨觀分析器

Pro.Surf凭借其区域地形扫描技术,能更快地确定形状与平整度。其大Z轴范围的同轴光学系统可探测孔洞与凹陷表面,最大视场与真实拼接功能轻松应对大型样品及多样品测量。升级至Pro.Surf+,更可实现粗糙度分析一体化操作。

Metro.Lab

Metro.Lab是一款紧凑型广域表面轮廓仪。它将卓越的测量性能与小巧的占地面积完美结合,特别适用于空间或预算受限但仍需可靠3D表面数据的应用场景。

選擇合適的表面處理方案,請放心選用轮廓仪 ——透過我們的「先試用後購買」方案,讓您輕鬆獲益。