表面測定タスク

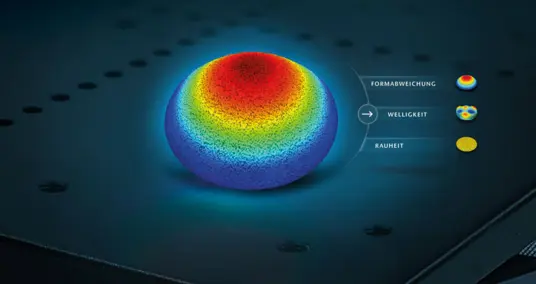

機能要件とプロセス要件は、地形と質感を定量化する標準化された表面パラメータを通じて表現される。以下のコレクションでは、各パラメータの詳細、評価のための推奨手法、および互換性のある測定システムについて説明する。

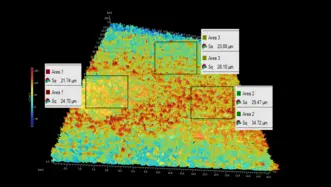

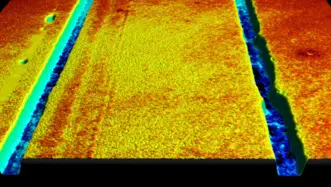

表面粗さ測定

Surface texture analysis in 3D. From Sa/Sq to Str/Sal for validating specifications and surface features.

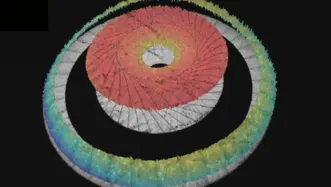

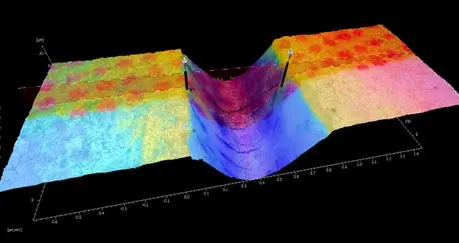

Maintain form and position tolerances

Verify form and position tolerances such as waviness, flatness, parallelism and tilt. Optical 3D surface metrology delivers reliable results—even in bores.

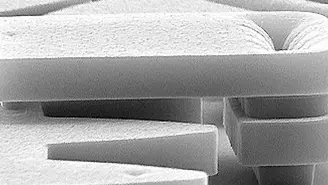

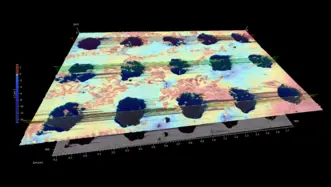

微細構造の表面計測

Topography & dynamics of microstructures and for nanotech. 3D geometry, roughness, and time-resolved motion.

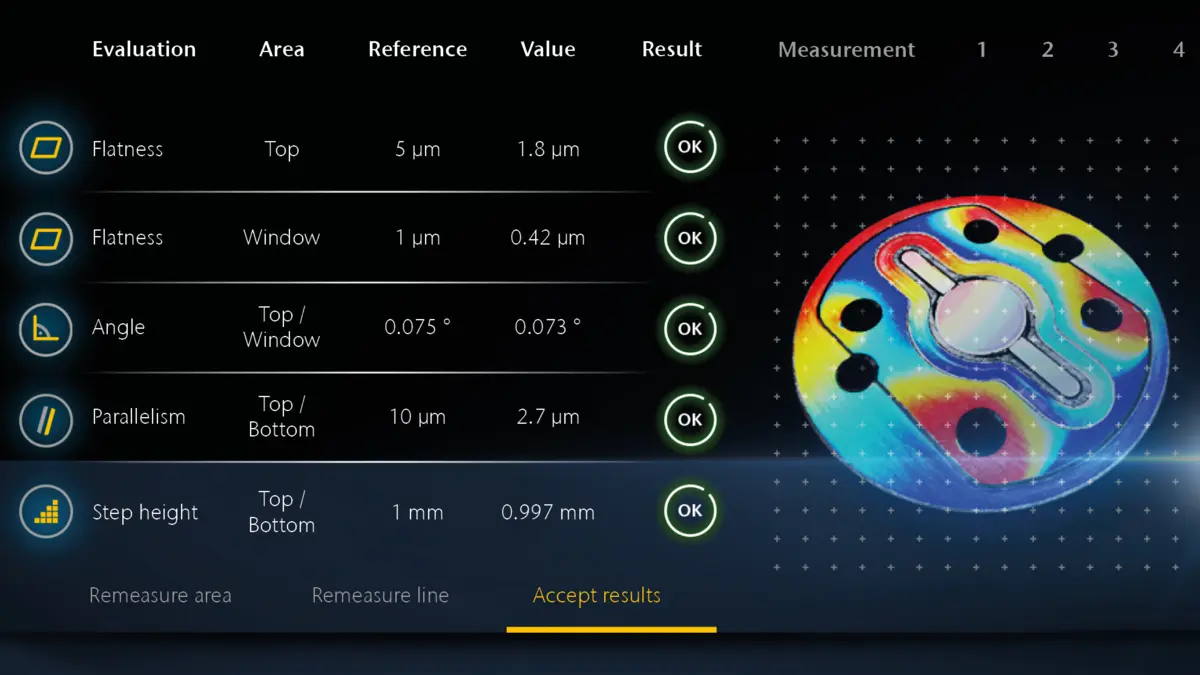

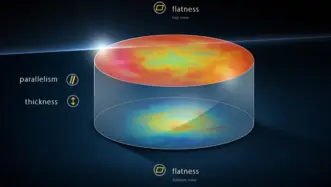

平坦度、厚さ、平行度

Flatness, thickness and parallelism (FTP) measurement combines top & bottom topography measurement in a single shot.

コーティングと層厚

Coating quality control in 3D. Assessing pre-coat texture, post-coat defects, and film thickness.

トライボロジー解析

Tribology analysis with 3D surface profiler. Inspecting friction, wear and lubrication performance.

合格/不合格分析

WLIs deliver fast, objective and easy to use pass/fail feedback from areal 3D data. Sub-nanometer Z and recipe-driven workflows support inline SPC.

様々な産業における表面計測技術

異なる産業分野では、機能性、信頼性、および規格適合性に応じて、それぞれ固有の表面仕様が要求されます。以下のページでは、一般的な用途と部品、代表的なパラメータ目標値、および適切な計測手法とシステムについて概説します。

様々な作業領域における表面処理ソリューション

計測システムの要件は、環境や業務機能によって異なります。製造業ではスループットと使いやすさが重視され、大学・研究開発機関・品質管理ラボでは柔軟性と精度が求められます。

ポートフォリオ ― マクロからミクロの地形学まで

マイクロプロファイラー

Micro.View systems are optimized for ultra-high-resolution measurements in the sub-nanometer range. With focused optics and high vertical resolution they enable detailed analysis of microstructures, surface finish and material distribution where even the smallest deviations matter.

マクロプロファイラ

Pro.Surf は広範囲をスキャンし、形状と平坦性をより迅速に測定します。Z 範囲の広いテレセントリック光学系は、高い段差や穴などの深い部分も測定可能です。最大の視野と True Stitching 機能により、大きな試験片、トレイ、または複数の部品を 1 回で測定します。Pro.Surf+ は、粗さ評価機能を追加して可能性をさらに広げます。

Metro.Lab

Metro.Lab is a compact, wide-area bench-top surface profiler. It combines high measurement performance with a small footprint — ideal for space- or budget-conscious applications that still require reliable 3D surface data.

自信を持って最適な表面プロファイラーをお選びください——「購入前に試用」という当社のアプローチのメリットを享受いただけます。

関連記事とストーリー

How CSI technology retrieves superior topography, form & roughness measurement data

Read how the optical technology of Coherence Scanning Interferometry (CSI) analyzes topography, form & roughness, where are sweet-spots, benefits and applications compared to related optical surface inspec…

Characterizing surface texture, roughness, imperfections and scratches

Optical polishing is a fabrication technique developed specifically to achieve minimal defects and smooth micro-roughness values. Polishing is a process that involves the use of free grains, usually suspen…

Interview with Prof. Dr. Albert Weckenmann about optical and tactile surface measurement technology

We talked with Prof. Dr. Albert Weckenmann of the University of Erlangen-Nuremberg, Germany, about the limitations of tactile surface measurement technology and the opportunities of non-contact methods.

Confirm flatness, roughness and step height – TopMap quality control on the factory floor

Consistently producing high-quality precision parts is better achieved when the supporting metrology is tightly integrated with the manufacturing process. By combining Polytec’s TopMap optical metrology wi…

Overview of optical methods for surface metrology

For applications where tactile surface measurement techniques have shortcomings, non-contact optical instruments have been developed to overcome these shortcomings. Especially with the development of compu…

How surface metrology reveals the finest forensic details

Forensic science plays a vital role in the criminal justice system by providing scientifically based information through the analysis of physical evidence. During an investigation, evidence is collected at…