测量卷筒材料的速度,监测传送带和单件货物的速度

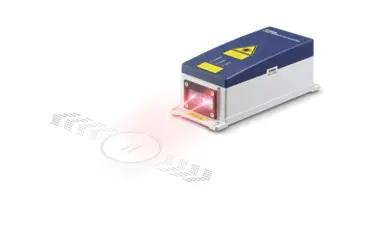

在线测量工艺速度对于许多工业过程的可靠控制和优化至关重要。它为无数其他应用奠定了基础,例如切割长度控制、长度测量、速度差检测。在这些过程中,速度测量采用激光多普勒技术实现。

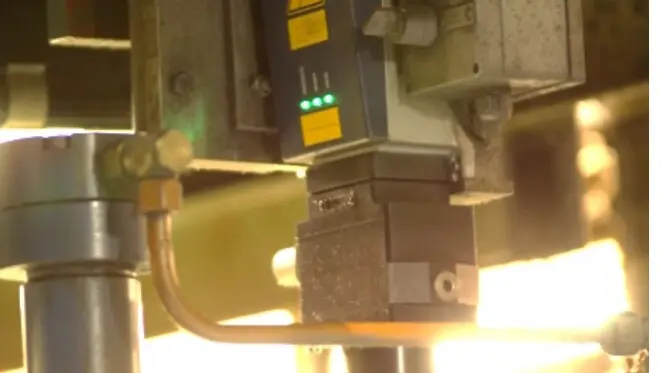

Polytec LSV激光表面测速仪作为理想的工艺速度传感器,几乎可在任何表面进行测量——包括受污染的油性表面、远距离或炽热材料,以及肮脏多尘的生产环境。其非接触式测量技术消除了编码器常见的负面影响,如因打滑和磨损导致的测量精度问题,同时避免对材料表面造成任何影响。

测量带材、片材、卷材的加工速度、差速及速度同步性

Polytec的光学传感器广泛应用于各行业,用于生产过程中精确的在线速度监测。当制造商对尺寸精度有严格要求时,无论是控制板材或带材厚度、监测进给速度,还是同步工艺速度与后续工序,全球制造商都信赖Polytec激光精密传感器。

- 连续铸造生产线中的坯料长度与速度测量

- 冷轧C型规中的速度监测,用于厚度测量与辊缝控制(AGC质量流量控制)

- 金属板材、纺织品或片状物料的切割速度同步控制

- 管材焊接等工序的速度同步

- 轧机架驱动张力同步或带材张力控制

- 电缆、电线及光纤绕线过程中的卷材同步

- 纸张/纸板涂布、退火线、热处理及加工后整理工序的停留时间测定

- ...(详见下文)

优势

//- Non-contact speed monitoring

- optical sensor prevents from slippage and wear

- Easy sensor integration

- into PLC with enhanced interface concept like Ethernet, fieldbuses, multi user etc.

- Compensate wavy material and altering distances

- with outstading measurement depth-of-field up to 200 mm and large stand-off-distances

- Reliable & efficient

- measurement technology enhancing process control, IP 66, 67

- Measure speed on any surface

- laser technology handles challenging materials like shiny, dusty, oily or red-hot

- Application-specific accessories

- like thermo-protective housing, air wipe and air amplifier, cooling plate, beam deflection etc.

速度同步 - 同步进给速度

在生产线上同步多个子流程、路径段或触发事件,实现匹配速度的优化流程:例如在切割工艺、卷绕工艺或焊接任务中。多个LSV传感器在不同位置测量速度或进给率。控制系统或PLC基于实时测量数据调节驱动装置或集成工艺,实现协调一致的流程控制。

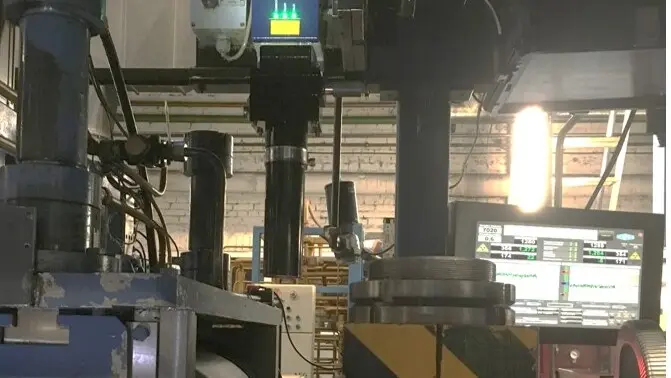

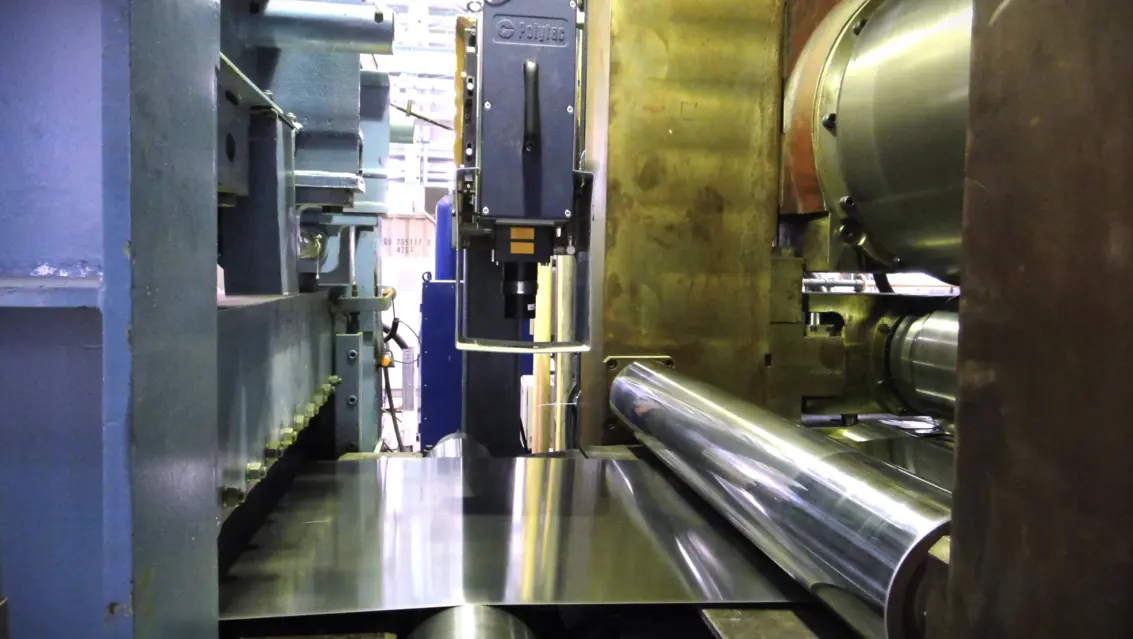

轧钢厂 Rolling mills

E.g. in large aluminum and steel rolling plants, the length and speed of aluminum and steel strips are measured to synchronize various sections.

切割工艺 / 定长切割 Cutting processes / cut to length

In the metal industry, LSV optical sensors are commonly used for synchronizing cutting devices in steel and aluminum cut-to-length processes.

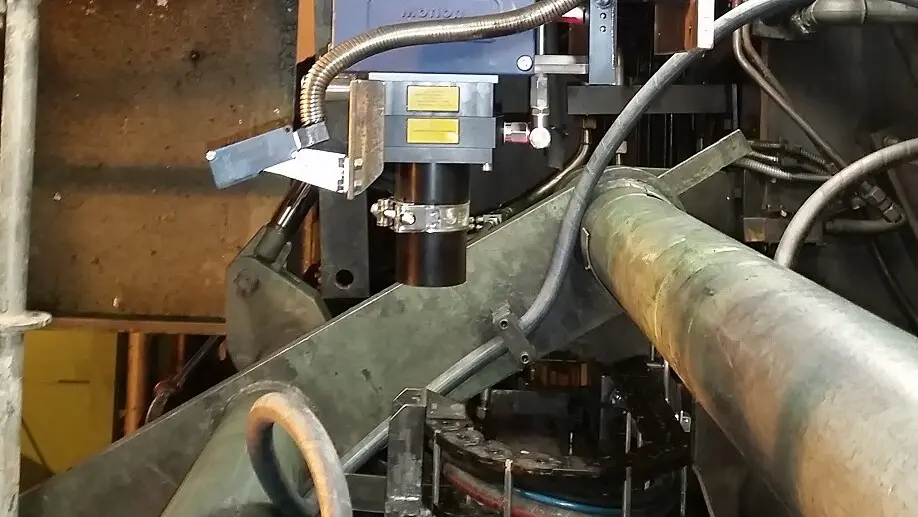

旋转管锯 Rotary tube saws

In rolling mills for tube production, LSV sensors help synchronize the saw blades with the manufacturing line speed with laser precision, thus ensuring they rotate at the exact same speed for cut-to-length at velocities of up to 10 m/s.

纸张及加工中的卷筒或卷材 Coils or rolls in paper & converting

In paper production or converting processes (e.g., rolled material and sheets), optical LSVs sensors are used to guide webs synchronously, e.g., during longitudinal cutting, when winding/ unwinding web goods or transferring them from one roll to another.

"...激光传感器物有所值:当生产多种不同品质的产品时,当测量轮需要频繁更换时。在特殊产品和某些无法控制滑移的表面上,或在公差要求严格的情况下——因为当整批产品超出公差范围时,那才是真正昂贵的时候!"

速度差测量 - 测量差速

为同步协调生产线的速度,需在两个或多个点位(例如轧机机架前后)或输送系统不同位置测量前馈速率或线速度。Polytec传感器可实现差速测量,用于基于相对速度控制工艺流程,如延伸率控制、质量流量控制或拉伸工艺。每台LSV传感器持续将实时速度值从测量位置传输至PLC,用于精确计算速度差v2 – v1。此基础可实现动态控制工艺触发点,例如:自动辊间距控制(AGC,调节辊间隙)、调节两辊间张力,或协调生产线速度。

Mass flow control in rolling mills

In single stand reversing or tandem cold rolling mills, the strip thicknesses and strip speeds are used to control the mass flow. Here, Polytec sensors provide individual speed measurements - highly accurate, without slippage and permanently calibrated. The differential speed measurement also perfectly helps regulating the material feed forward rate.

缩径轧机 Stretch reducing mills

In skin pass or stretching mills, the elongation ("degree of stretching") is calculated by measuring the differential length between inlet and outlet tracks - practically monitored via differential speed. Skin pass degree formula (%)= ((voutlet - vinlet) / vinlet) x 100%. This allows very precise control of material elongation, e.g. for tensile strength and yield strength.

轧制 Rolling e.g. tailored blanks

In rolling mills, where strip segments with variable thicknesses are rolled, like for tailored rolled blanks, the differential speed is measured with high temporal resolution in order to precisely control the roll gap.

纸张、纸板及包装材料 Paper, cardboard & packaging

LSVs measure speed differences between rolls and webs during winding and unwinding to monitor and balance tension. They are also used to synchronize individual sheets in cutting processes.

焊接过程中的同步化 Synchronization in welding processes

In welding lines (e.g., in the metal and pipe industry), the pipe or feed speed at weld head is used for monitoring and controlling the power to weld head and for optimizing the weld power for a consistent weld quality.

塑料与纺织工艺 Converting & textile processes

Velocity difference can become key for harmonizing individual rolls in longitudinal cutting, for matching roll and web speed in winding and unwinding processes, for tension control or in extrusion processes.

生产线中的激光精准速度监测——工作原理

咨询我们的专家

全新测量仪免费享三年保修,卓越服务与可靠支持:我们的PolyXpert服务涵盖现场支持、传感器集成与调试,提供定制解决方案、校准或维修服务,以及毫不妥协的传感器更换计划。选择Polytec,您投资的是可靠的合作伙伴关系、专业技术与信任!