控制您的切割长度、剪切或修剪工艺

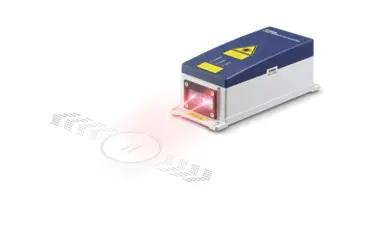

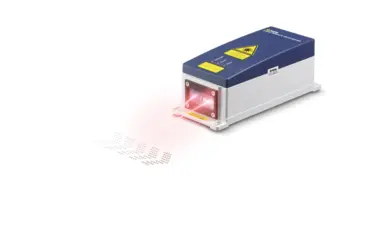

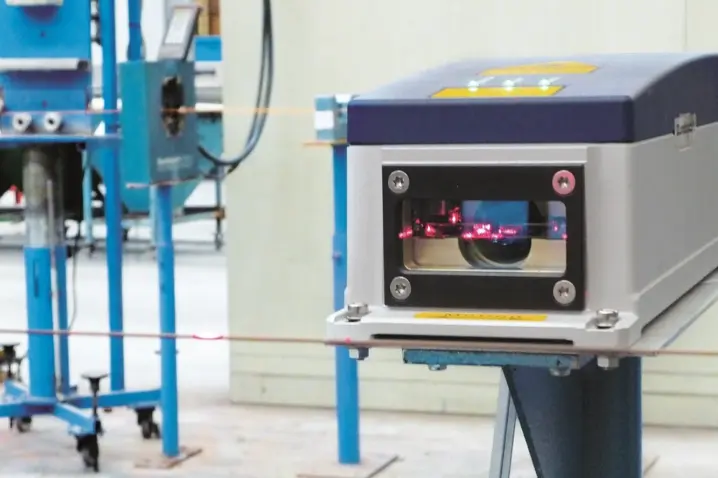

Polytec 的 ProSpeed® 激光表面测速仪是享誉全球的非接触式传感器或光学编码器,可实现精确的长度切割和切割控制,广泛应用于金属、木材和建筑材料(如矿棉或石膏板)、纸张和包装、塑料和加工工艺,以及电缆和电线等行业。该激光传感器取代了接触式轮和编码器,消除了打滑和磨损,通过提高长度公差并减小安全裕度来节省材料。此外,Polytec 传感器还能逐刀逐班地提高精度和产量。

- 可监控连续和零散产品(如卷材、板材、棒材、管材、板坯或面板)的长度和进给过程。

- 可控制木材加工中固定式或飞锯、加工中剪切机、塑料和纺织品切割刀、分切机或旋转式管材锯的切割长度。

- 可验证切割产品的长度并跟踪材料,用于下游工序或质量分配。

与实际加工速度同步控制切割、剪切和裁剪

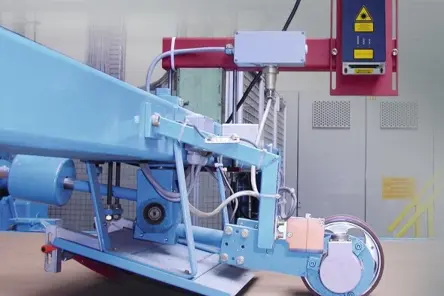

在实际应用中,同一传感器通常可同时处理多项任务:测量实际生产线速度、触发预警或切割信号,以及使飞锯等运动部件与产品同步。例如,对于钢材、塑料或纸张等材料,LSV 传感器有助于使切割工具与材料速度同步。

LSV 激光传感器可测量几乎所有材料的加工进给速度和生产速度,即使在粉尘、污垢较多的生产环境中以及高温钢材上也能正常工作。其非接触式速度测量避免了传统编码器或驱动器常见的打滑和磨损问题。LSV 光学传感器不会对产品表面造成任何影响,并且可以通过所有常用接口(例如 LAN、ProfiBus 或 ProfiNET 等)轻松集成到您的 PLC 和生产系统中。

Cut-to-length in steel & metals

- Hot and cold, flat, long and round products

- Synchronization of vertical shears, slitting lines, flying saws and rotary tube saws

- Torch cutting on billets, slabs or blooms

- Cutting of heavy steel plates, thin or trapezoidal sheets and profiles

- Crop optimization with flying guillotine shears

Polytec公司的LSV激光表面测速仪为我们提供了过程可靠且高度精确的速度和长度信息——即使在最恶劣的环境条件下亦是如此。这使得LSV激光传感器成为管材轧制机中完美匹配的传感器技术。

优势

//- Avoid slippage and wear

- with non-contact, optical cut to length control

- Higher accuracy, increased yield

- Laser-based cutting allows reduced safety margins, producing less scrap and reliable output

- Compensate "jumping" material and varying distances

- with outstading measurement depth-of-field up to 200 mm and large stand-off-distances

- Easy sensor integration

- into PLC with enhanced interface concept like Ethernet, fieldbuses, multi user etc.

- Measure on any surface

- laser principle masters challenging shiny, dusty, oily or red-hot materials

- Application-optimized accessories

- like thermo-protective housing, air wipe and air amplifier, cooling plate, mounting and adjustment platform, beam deflection etc.

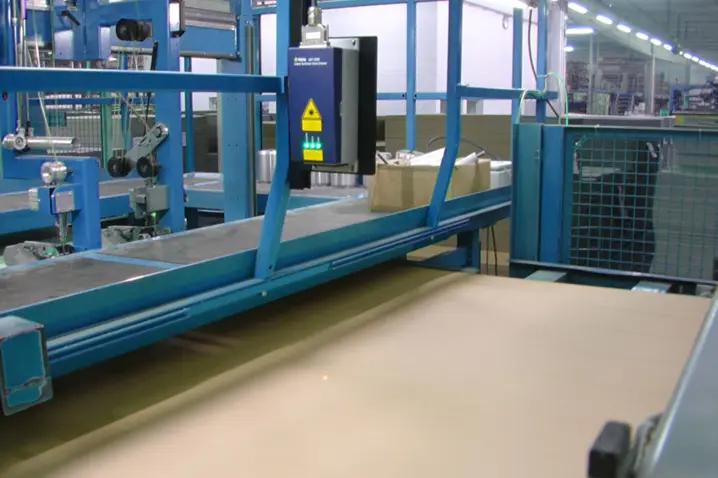

按建筑和隔热材料及木材的长度切割

- Cut length of products sold by length like mineral wool, glass wool, insulation

- Drywalls or gypsum boards, plasterboards

If a product line does not stop during the cutting process, the cutting or shearing device as to be moved as a flying cutting device in sync with the line speed for a straight cut. LSV optical sensors help synchronize the shearing device with the product by simultaneously measuring and providing length and speed parameters to the production system.

纸张、纸板及瓦楞纸板的剪切与定长切割

- Cut‑to‑length control for paper and cardboard webs, including corrugated board lines

- Controlling the cut length and speed of cardboards and packaging material

切割电缆、电线或光纤的长度

- Polytec LSVs are used in the cable and wire industry to control cutting lengths on cables and wires

- Cut length of sheathing and insulation materials.

由于测量精度与线速度无关,即使是最微小的运动也能被精确捕捉。这对我们的线缆应用至关重要。该测量系统可轻松集成至生产流程,而可见激光在宽广测量范围内显著简化了对准操作。

挤出、加工与塑料制品的切割长度

- 塑料薄膜、挤出型材、板材及其他加工产品的长度/速度监测与切割控制。

- 涂覆或层压工艺中用于停留时间控制的非接触式编码器功能。

相较于接触式编码器,用户可在高速运行时获得更稳定的长度控制,在重量、涂层或表面纹理变化时实现更优的重复性,且不会在敏感表面留下轮痕。

光学长度与速度测量,实现终极精密工艺控制