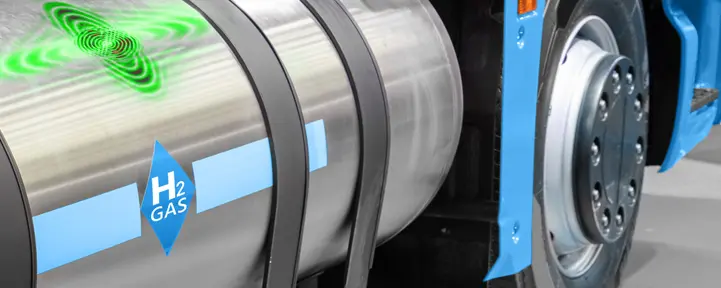

Improved quality in hydrogen tanks, blowers, pumps & compressors

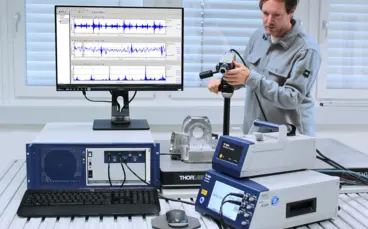

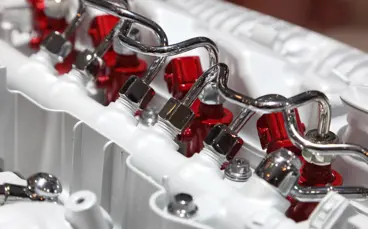

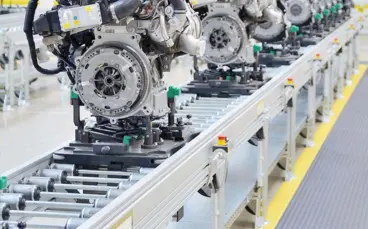

In fuel cell testing, material research of hydrogen tanks or of components such as injection valves, compressors (air system), blowers or pumps on the cooling side, Polytec Laser Doppler vibrometers assist in thourough vibration analysis. Polytec’s range of non-contact vibration measurement sensors help validate the FE model, visualize the operational deflection shape (ODS) of both the single component or assembly, can identify components with highest contribution to fuel cell vibration and thus noise or for NVH testing(noise, vibration and harshness).

Measure and validate your H2 components

Why laser vibrometers for H2 component testing

- Non-contact

- Non-reactive, even in hard-to-reach areas

- Auto focus

- Reliable measurement results at short and long distances

- Reliable

- Unaffected by ambient noise

- High precision

- Valid data detecting even small differences

Hydrogen Fuel Cell Vehicles (HFCV) on the rise

However, one major problem that electric vehicles have to overcome is the limited range one can drive before the need to recharge the BEV batteries. This is not only a problem with passenger BEV’s but also even more with commercial vehicles such as Trucks and Buses where a long travel range is needed.

The automotive industry is looking for solutions how to extend the range of carbon neutral vehicles. In contrast to BEV the hydrogen-based fuel cell (FC) technology overcomes the range problem. This is because larger hydrogen fuel tanks can store more energy and on top, the refueling process is faster compared to a battery recharge. Thus, countries not only in Asia are heavily funding the fuel cell technology and fuel cell infrastructure. FC technology acceptance especially in larger commercial vehicles such as trucks and buses is growing.

Quiet & reliable fuel cells: NVH testing of hydrogen technology

To become fully accepted in vehicles the fuel cell technology has to be reliable, safe and comfortable. Directly related to comfort is the noise level of the vehicle which should be as low as possible. Thus, vehicle manufacturers need to ensure that each system component used in the vehicle is not dominating the overall noise level by tonal noise.

Test H2 components on a broad frequency bandwidth!

Related products

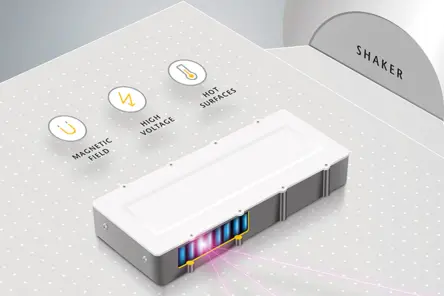

VibroScan QTec Xtra

VibroScan QTec Xtra measures vibrations in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

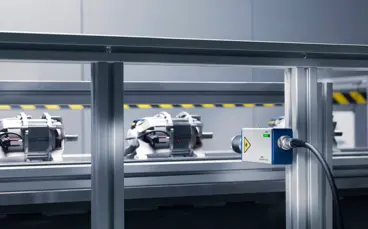

SonicTC QuickCheck

Multi-channel, PC-based testing software for fully or partially automatic process monitoring and quality control based on the vibration behaviour of manufactured products. SonicTC QuickCheck is a flexible tool for acoustics and vibration measurement in industrial quality control. The versatile fields of application reach from series production to in-process development.

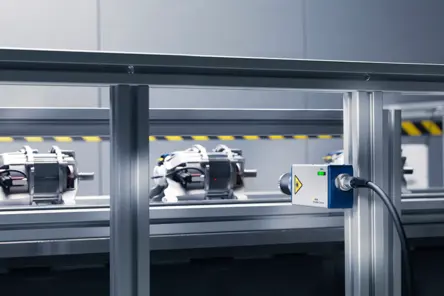

IVS-500 Industrial Vibration Sensor

The IVS-500 Industrial Vibration Sensor is key to fast and non-contact vibro-acoustic quality inspection, structure-borne noise analysis and reliable pass-fail decisions. Its robust and compact design enables a smooth integration into process control systems for in-line and production testing up to 100 kHz, whenever requiring short cycle times like for end-of-line tests. The sensor is wear-free and avoids expensive servo-mechanisms or noise protection cabins.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters—get in touch with us today.