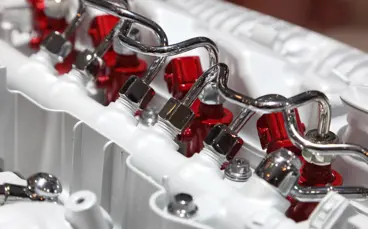

End-of-line or in-line quality control

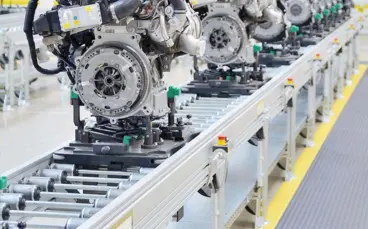

End-of-line (EoL) testing is the process of checking the quality of the manufactured product at the end of the production line and assessing it as OK or not OK. In contrast to EoL testing, in-line testing involves testing and evaluating product quality directly during the manufacturing process. Depending on the product to be tested and the quality criteria, different sensors are used to ensure the quality of the delivered product.

Learn how laser-optical sensors and non-contact testing of the acoustic signature helps in end-of-line testing!

Vibro-acoustic end-of-line quality control

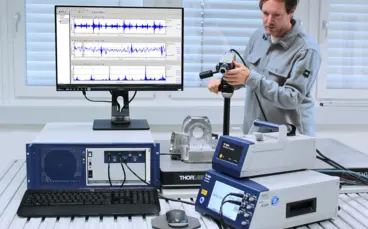

Accelerometers, microphones or Laser Doppler Vibrometers (LDV) are generally used when quality control is required for vibration, acoustics and/or structure-borne noise. Laser Doppler vibrometers have the advantage of being non-contact and therefore do not require a sensor feed as is the case with accelerometers. Also, unlike a microphone, LDVs cannot be influenced by ambient noise.

Advantages of EoL vibration testing

- Non-contact: Non-reactive, even in hard-to-reach areas

- Auto focus: Reliable measurement results at short and long distances

- Reliable: Unaffected by ambient noise

- High precision: Valid data detecting even small differences

- Easy integration: Interfaces for PLC and test systems

No budget? Just measure.

Whether you need contract measurements, equipment rental, or leasing, our scalable services deliver precise data—without the overhead of major investments. Ideal for short-term projects, occasional use, or limited budgets. Get in touch with us—together we will find the right solution for your specific needs!

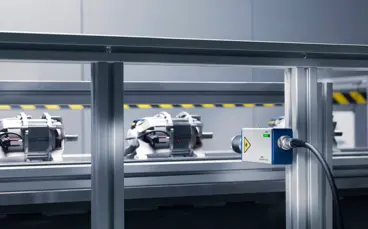

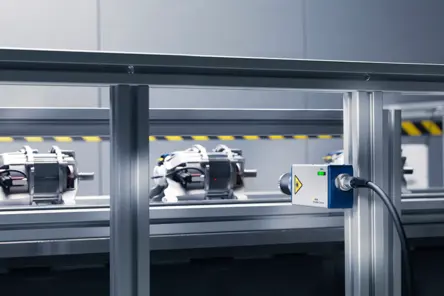

End-of-line vibration testing with laser vibrometers

In addition to the reliability of the test equipment, end-of-line testing also depends on easy integration into the test station and automation capability to achieve the highest possible test throughput. Laser Doppler vibrometers (LDV) offer advantages in all these areas.

Because vibrometer EoL testing works in a non-contact way with a flexible, adjustable working distance, LDVs can reliably measure at some distance from the test specimen. In addition, a signal can be recorded and analyzed at measurement points that are inaccessible to accelerometers. The high accuracy means that extremely precise data can be recorded and even the smallest changes in test results can be detected. Integration into the production system and communication with the PLC process control system is also possible.

Stand-off distance, frequency and min/max acceleration values?

Become an EoL testing expert: tips, tricks & video tutorials

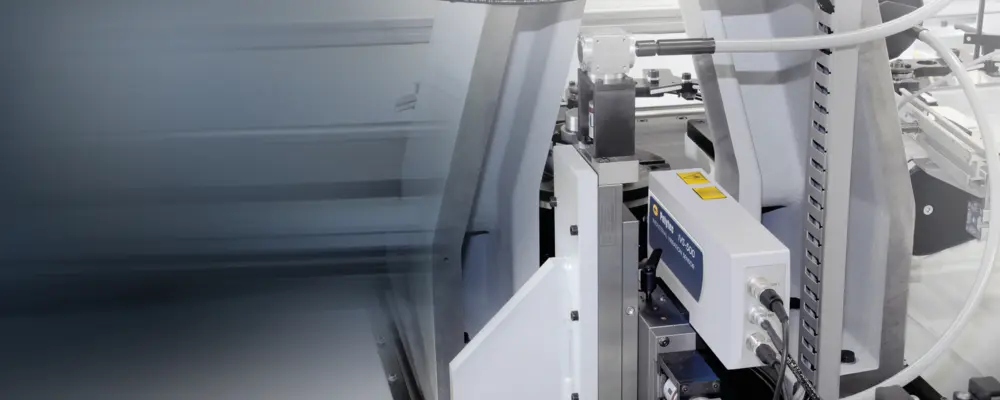

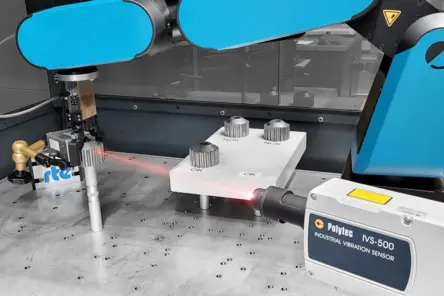

The IVS-500 Industrial Vibration Sensor from Polytec is a dedicated and flexible measuring device for end-of-line testing on behalf of the vibro-acoustic signature or a produced part or assembly.

This exclusive section (login) provides an overview, the basics of acoustic testing using laser vibrometers and a practical benchmark and comparison to alternative EoL testing methods, as well as valuable tips & tricks in video tutorials for the use and handling of the IVS-500 Industrial Vibration Sensor - for starters, users, integrators and experts.

Related products

VibroScan QTec Xtra

VibroScan QTec Xtra measures vibrations in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

SonicTC QuickCheck

Multi-channel, PC-based testing software for fully or partially automatic process monitoring and quality control based on the vibration behaviour of manufactured products. SonicTC QuickCheck is a flexible tool for acoustics and vibration measurement in industrial quality control. The versatile fields of application reach from series production to in-process development.

IVS-500 Industrial Vibration Sensor

The IVS-500 Industrial Vibration Sensor is key to fast and non-contact vibro-acoustic quality inspection, structure-borne noise analysis and reliable pass-fail decisions. Its robust and compact design enables a smooth integration into process control systems for in-line and production testing up to 100 kHz, whenever requiring short cycle times like for end-of-line tests. The sensor is wear-free and avoids expensive servo-mechanisms or noise protection cabins.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters—get in touch with us today.