NVH and how to design quiet vehicles

NVH (noise, vibration, harshness) describes the analysis of the influences and sources of noise and vibration behavior in vehicle design and engineering. The objective of NVH analysis or NVH test methods is to optimize noise and acoustics in conjunction with reduced vibration behavior of vehicles and vehicle components. NVH is used for vehicle design, car body design, interior design and more. NVH testing is the crucial basis for reducing unwanted squeaking or rattling noises and thus a quality feature and acoustic signature of any component or complete vehicle.

NVH analsyis and non-contact NVH testing as a service?

NVH testing without contact and mass-loading

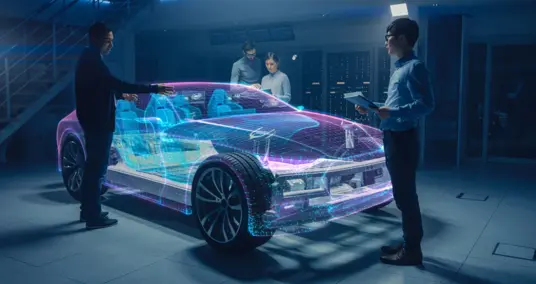

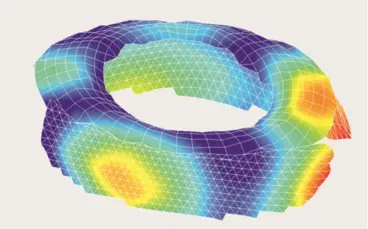

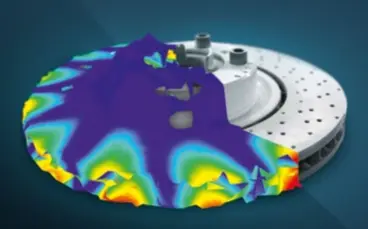

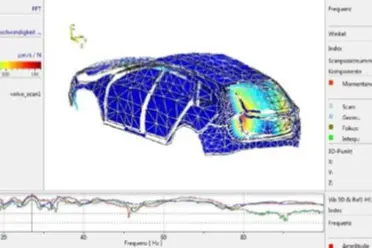

Droning, humming, squeaking and rattling are typical acoustic problems found in vehicles – and particularly in lightweight construction. They are a source of irritation to end customers and consequently need to be eliminated. The term NVH (noise, vibration and harshness) is an umbrella term used to refer to all those measures that enhance acoustic comfort for drivers and passengers alike. Developing quiet, low-vibration products is a joint simulation and testing task. Polytec’s Scanning Vibrometers allow you to unveil sources of sound radiation quantitatively and with high spatial resolution. Inverse panel contribution measurements and qualification of damping materials (sound package) are made a great deal easier with the automatic scanning process.

For precise and reliable examination of the source of sound and vibration, use PSV Scanning Vibrometers from Polytec and identify the structure-borne sound transmission paths and the causative deflection shape. The 3D visualization of the operational deflection shapes helps the NVH engineer to quickly come up with ideas to solve the problem – even just before production starts.

Describe your NVH analysis and task

NVH acoustics testing using the e-line method

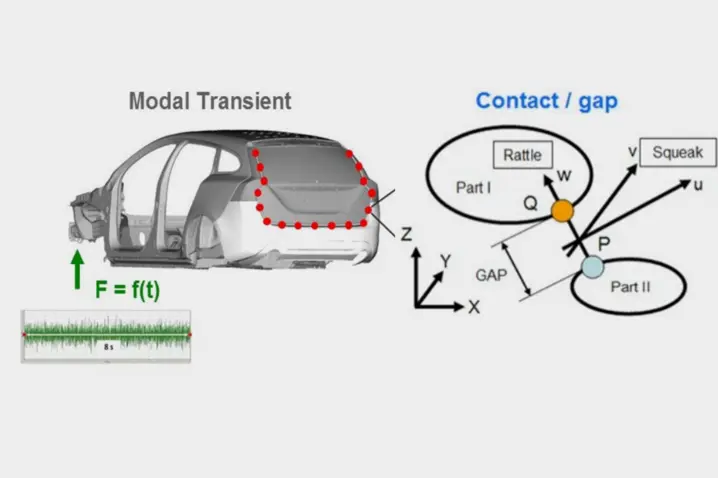

Squeak and rattle (S&R) refers to a sub group of NVH acoustics, testing for undesirable squeaking and rattling noises as one important factor for customer satisfaction. S&R is a non-linear phenomenon that is heavily dependent on the relative displacements of neighboring components.

In NVH acoustics testing, the E-line method focuses on calculating and evaluating the relative displacement between two automotive parts, which is the main cause for S&R, chafing and abrasive wear. NVH sensor solutions from Polytec help perform NVH measurements in the time domain and in a local coordinate system along the E-line, thus capturing the true displacement in the rattle direction and in the squeak plane.

NVH for defined acoustics in door slam testing

When asking people about their first impression of a new car when entering the passenger cabin, it's either the smell or its sound when closing the door. Thus, the door slam test has become an integral part of NHV analysis for optimizing comfort as well as the perception of quality. In order to measure structural borne noise, using full-field vibration measurement for determining the vibrational velocity in the time domain are of significant value. The Multipoint Vibrometer allows measuring with up to 48 locations synchronously, providing vibration measurement data without any contact or mass-loading influences especially on thin sheet metal panels.

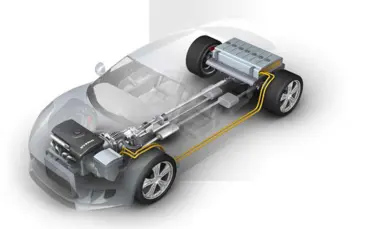

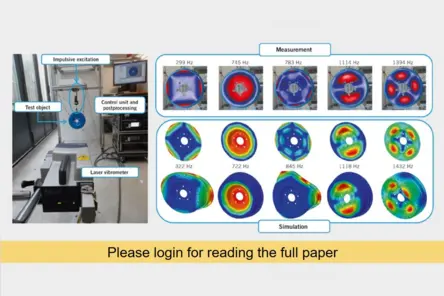

NVH in electric mobility (EV) – vibration measurement & analysis

Wheel hub motors show benefits in packaging, but also bring in new challenges in terms of NVH due to their installation position. A dedicated group of the Otto von Guericke University in Magdeburg used optical vibration measurement technology for analyzing the vibrations behavior of external rotor electric motors in order to optimize the acoustics of wheel hub motors. Read more about the research on close-to-wheel electric drives in this article. Please sign in for downloading the full paper.

Related products

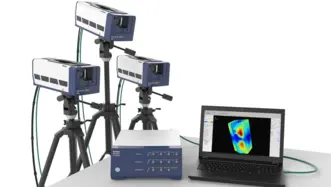

VibroScan QTec Xtra 3D

VibroScan QTec Xtra 3D measures vibrations triaxially in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra 3D ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

VibroScan QTec Xtra

VibroScan QTec Xtra measures vibrations in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

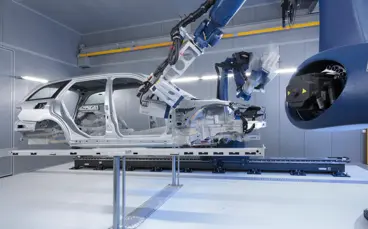

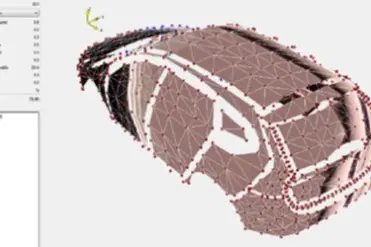

RoboVib®

By combining a 3D scanning vibrometer and an industrial robot, RoboVib® forms an automated test station for measuring everything from complex components to complete vehicle bodies. Reduce testing time and expenses as well as time to market significantly in experimental modal analysis. Conduct comprehensive 360° testing of a vehicle body, for example, within only one-two days and overnight instead of weeks of preparation with conventional test setups.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters—get in touch with us today.