Manufacturing medical devices with maximum precision

People’s health is always the top priority in medicine. Therefore it is particularly important to ensure a consistent level of quality and reliability in medical device production. High-precision measurement and rapid analysis are very much in demand here, since even minor deviations can sometimes lead to unforeseeable and serious consequences.

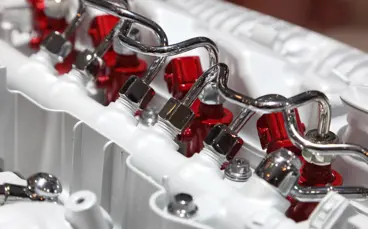

Production testing on membranes for nebulizers and medical instruments

Pari GmbH manufactures nebulizers to treat respiratory diseases that accurately meter the liquid drug. The liquid is pressed through the holes in a membrane, which is stimulated to produce ultrasonic vibrations by piezo elements, and atomized. Using laser vibrometry guarantees a consistent nebulizer quality and thus an excellent reproducible drug effect for the patient.

Polytec’s laser vibrometers also allow the detailed examination of the membrane’s vibration behaviour at product development stage and thereby enable continuous optimization of design and performance.

Acoustic quality control with laser precision

Related products

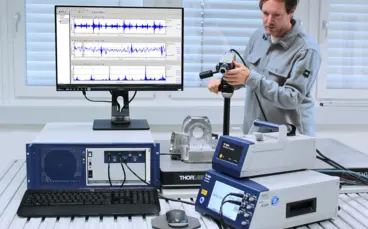

VibroOne

The laser Doppler vibrometer VibroOne® is the one-box solution for non-contact vibration measurement up to 3 MHz. It is specifically designed for tightly packed setups, whether in research laboratories, challenging production environments or for non-contact analysis of tiny details on microstructures or biomedical probes. The optional inline HD+ camera helps positioning the laser precisely and provides proper test documentation.

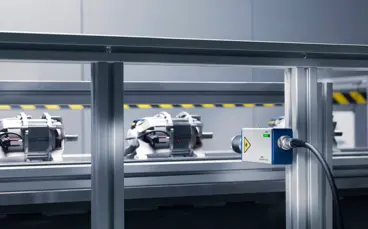

IVS-500 Industrial Vibration Sensor

The IVS-500 Industrial Vibration Sensor is key to fast and non-contact vibro-acoustic quality inspection, structure-borne noise analysis and reliable pass-fail decisions. Its robust and compact design enables a smooth integration into process control systems for in-line and production testing up to 100 kHz, whenever requiring short cycle times like for end-of-line tests. The sensor is wear-free and avoids expensive servo-mechanisms or noise protection cabins.

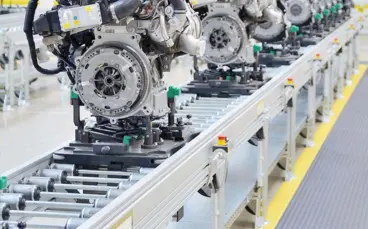

SonicTC QuickCheck

Multi-channel, PC-based testing software for fully or partially automatic process monitoring and quality control based on the vibration behaviour of manufactured products. SonicTC QuickCheck is a flexible tool for acoustics and vibration measurement in industrial quality control. The versatile fields of application reach from series production to in-process development.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters—get in touch with us today.