Acoustic testing of actuators and drives despite environmental noise

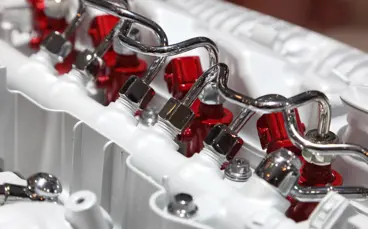

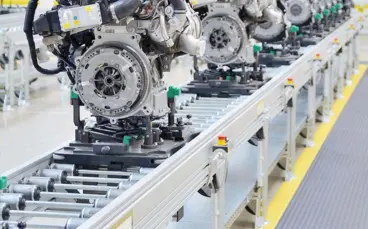

Sounds like rattling, whining, clicking or chirping are acoustic indicators that can be clearly identified as the proprietary acoustic signature of manufactured parts, which can be deteced by acousitc testing without contact using laser Doppler vibrometers. Drive systems which contain damaged or warped components – such as cogs – often generate unwanted operating noises and need to be detected and rejected during production. A product defect, especially in highly stressed components, can lead to the complete failure of the system and the end consumer complaining. Laser vibrometry has proven to be the perfect measurement technique for this process, as it allows for non-contact, high-precision, automatic and reliable quality control using frequency and order analyses.

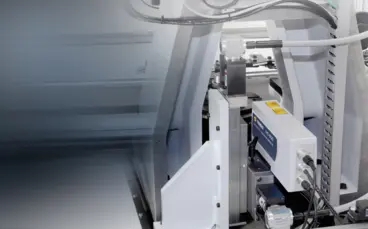

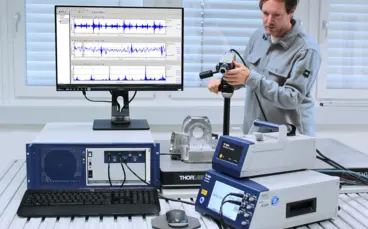

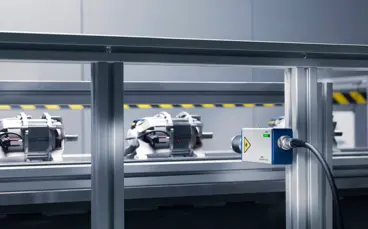

In automated noise test stations, you can use laser vibrometers from Polytec to affordably, reliably and efficiently check your products with very short cycle times. Unlike microphones, the laser vibrometer only measures structure-borne sound and is not influenced by environmental noise. This saves you from using noise protection cabins. So, for example, you can ensure that micro drives have not been supplied with defects or disturbing noise. So customer complaints about “rattling”, “whining”, “clicking” or “chirping” are a thing of the past. You can define the perfect spot for acoustic quality control in advance by analyzing the component in detail with a PSV Scanning Vibrometer.

Acoustic signature reveals defects

When manufacturing motor pump units for electro-hydraulic steering gears, during the complete check it is standard practice to examine even several operating conditions from standby to full load. Carrying out an order analysis with laser vibrometers from Polytec allows detailed conclusions to be drawn as to the cause of the fault, such as the pump shaft’s true running accuracy being inadequate. By measuring the outside surface with a laser spot in a non-invasive way, the true acoustic signature of parts allow quick and effective pass-fail decisions.

Acoustic quality control with laser precision

Related products

IVS-500 Industrial Vibration Sensor

The IVS-500 Industrial Vibration Sensor is key to fast and non-contact vibro-acoustic quality inspection, structure-borne noise analysis and reliable pass-fail decisions. Its robust and compact design enables a smooth integration into process control systems for in-line and production testing up to 100 kHz, whenever requiring short cycle times like for end-of-line tests. The sensor is wear-free and avoids expensive servo-mechanisms or noise protection cabins.

SonicTC QuickCheck

Multi-channel, PC-based testing software for fully or partially automatic process monitoring and quality control based on the vibration behaviour of manufactured products. SonicTC QuickCheck is a flexible tool for acoustics and vibration measurement in industrial quality control. The versatile fields of application reach from series production to in-process development.

VibroOne

The laser Doppler vibrometer VibroOne® is the one-box solution for non-contact vibration measurement up to 3 MHz. It is specifically designed for tightly packed setups, whether in research laboratories, challenging production environments or for non-contact analysis of tiny details on microstructures or biomedical probes. The optional inline HD+ camera helps positioning the laser precisely and provides proper test documentation.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters—get in touch with us today.