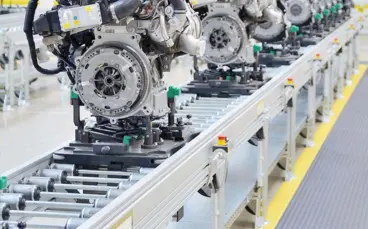

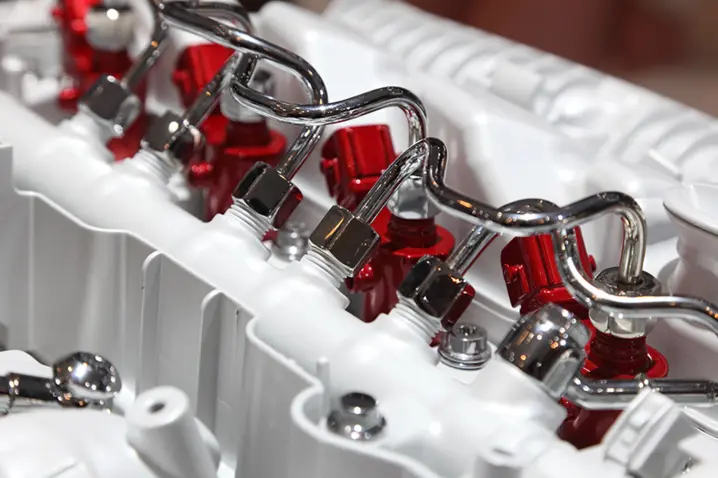

Zero-fault production of injection valves

Greater energy efficiency and lower environmental impact are two fundamental requirements for combustion engines. In this regard, it is essential that the components’ planned parameters are always exactly adhered to, so as to ensure faultless production without any rejections or rework. Use Polytec vibrometers for zero-fault production testing.

Quality inspection of injection valves and more

To name just one critical example, Polytec’s laser vibrometers are used to carry out a complete check on injection valves for vehicles’ combustion engines. The valves’ opening and closing behavior is checked during this process so the fuel throughput can be optimally controlled.

Acoustic quality control with laser precision

Related products

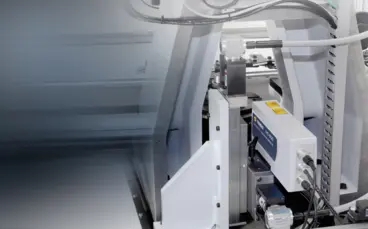

IVS-500 Industrial Vibration Sensor

The IVS-500 Industrial Vibration Sensor is key to fast and non-contact vibro-acoustic quality inspection, structure-borne noise analysis and reliable pass-fail decisions. Its robust and compact design enables a smooth integration into process control systems for in-line and production testing up to 100 kHz, whenever requiring short cycle times like for end-of-line tests. The sensor is wear-free and avoids expensive servo-mechanisms or noise protection cabins.

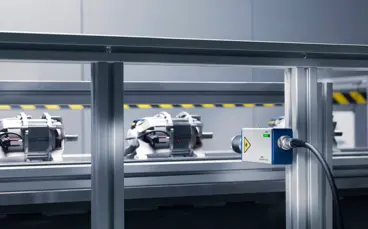

SonicTC QuickCheck

Multi-channel, PC-based testing software for fully or partially automatic process monitoring and quality control based on the vibration behaviour of manufactured products. SonicTC QuickCheck is a flexible tool for acoustics and vibration measurement in industrial quality control. The versatile fields of application reach from series production to in-process development.

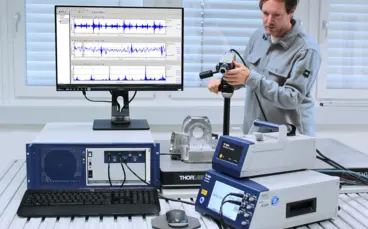

VibroOne

The laser Doppler vibrometer VibroOne® is the one-box solution for non-contact vibration measurement up to 3 MHz. It is specifically designed for tightly packed setups, whether in research laboratories, challenging production environments or for non-contact analysis of tiny details on microstructures or biomedical probes. The optional inline HD+ camera helps positioning the laser precisely and provides proper test documentation.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters—get in touch with us today.