Production testing and quality control of white goods

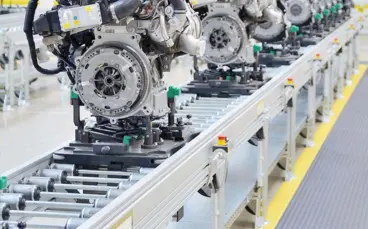

In the consumer and capital goods industries, both product optimization and process optimization play a vital role when it comes to economic success. Experience has shown that spot checks performed on systems selected at random do not result in a reliable outcome. Only carrying out a complete check on the finished products guarantees a high quality standard. You should therefore opt to perform vibration tests with laser vibrometers from Polytec. Vibration analysis is ideal for distinguishing good products from faulty ones, which is why it is advisable to use vibrometers for quality control purposes. Laser vibrometry has established itself as the method of choice for non-contact testing. With the help of the laser vibrometer, the system reliably detects potential defects such as faulty or loose components or machine imbalance and provides information on the specific cause of the fault.

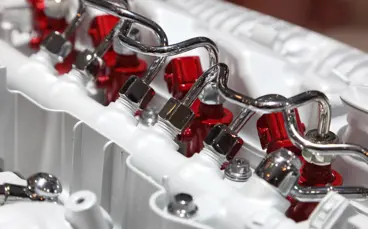

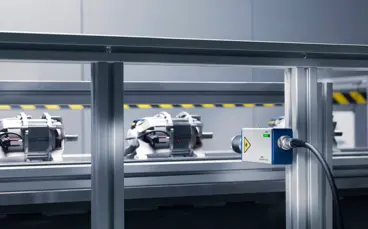

Noise and vibration inspection on motors for household appliances

Electrically driven household appliances or their components which generate unwanted vibrations and noise are reliably detected in production by laser vibrometers and removed from the process. Examples include washing machines, vacuum cleaners and electric toothbrushes.

Acoustic quality control with laser precision

Related products

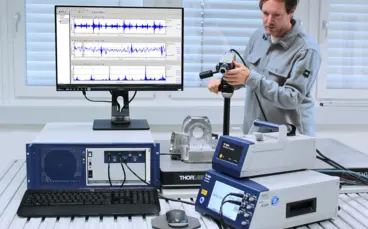

VibroOne

The laser Doppler vibrometer VibroOne® is the one-box solution for non-contact vibration measurement up to 3 MHz. It is specifically designed for tightly packed setups, whether in research laboratories, challenging production environments or for non-contact analysis of tiny details on microstructures or biomedical probes. The optional inline HD+ camera helps positioning the laser precisely and provides proper test documentation.

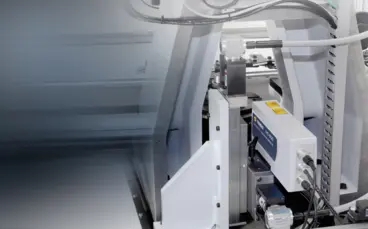

IVS-500 Industrial Vibration Sensor

The IVS-500 Industrial Vibration Sensor is key to fast and non-contact vibro-acoustic quality inspection, structure-borne noise analysis and reliable pass-fail decisions. Its robust and compact design enables a smooth integration into process control systems for in-line and production testing up to 100 kHz, whenever requiring short cycle times like for end-of-line tests. The sensor is wear-free and avoids expensive servo-mechanisms or noise protection cabins.

SonicTC QuickCheck

Multi-channel, PC-based testing software for fully or partially automatic process monitoring and quality control based on the vibration behaviour of manufactured products. SonicTC QuickCheck is a flexible tool for acoustics and vibration measurement in industrial quality control. The versatile fields of application reach from series production to in-process development.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters—get in touch with us today.