Optimize lightweight construction with laser precision

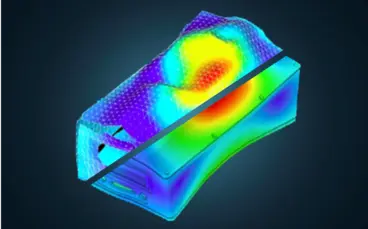

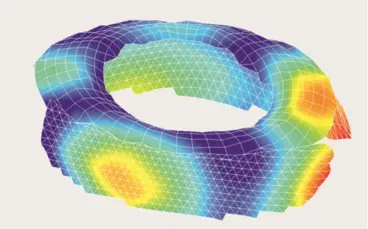

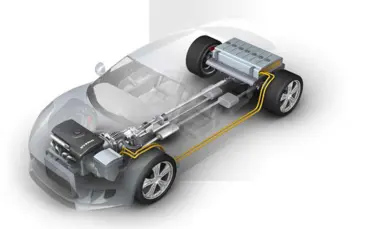

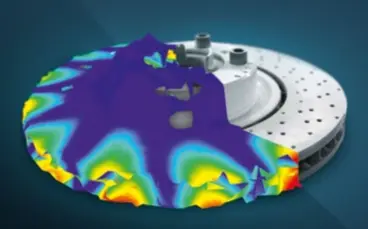

Lightweight construction forms the basis for better construction. The body shell offers the best potential in this regard. High tensile steels, aluminum and composite materials made from carbon fiber-reinforced plastic are being used instead of conventiopmal car body steel. Joining methods such as bonding and riveting are entering production processes, making simulation calculations susceptible to faults since joint attenuation cannot be determined with any real degree of certainty. Consequently, proof from an experimental modal analysis is more important than ever before during FE model validation.

Since fewer prototypes are used nowadays, each optimization step needs to be faster and more reliable. Even lightweight bodies tend to drone, which is precisely why high-frequency mode validation is a topic for the future too as regards the acoustic calculation. A well-validated inventory model is normally used as a basis for the next generation. The better the model, the earlier a new vehicle’s properties can be calculated.

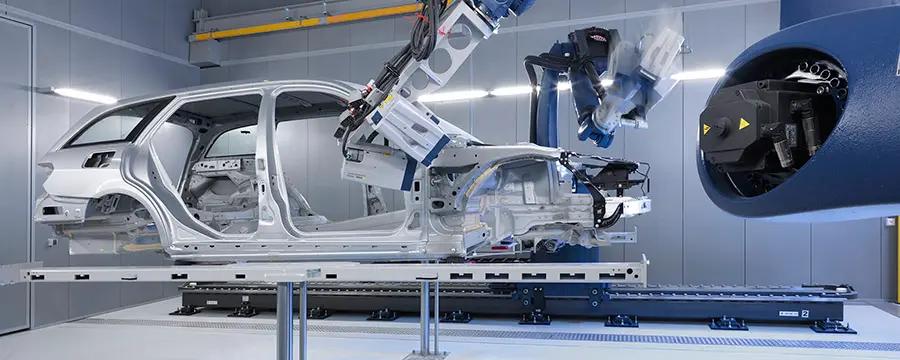

Lightweight bodies long for lightweight measuring technology, the non-contacting method per laser light is the ideal sensor technology. In offering you the 3D Scanning Vibrometers and the automated RoboVib® solution, Polytec is providing you with a highly productive tool that is extremely beneficial to you:

- Avoid impact on the sample thanks to zero mass loading

- Directly transfer the geometries data from FE models

- Automated measurement even overnight saves time

- High spatial resolution allows validating acoustic simulations

Related products

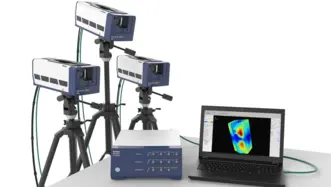

VibroScan QTec Xtra 3D

VibroScan QTec Xtra 3D measures vibrations triaxially in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra 3D ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

VibroScan QTec Xtra

VibroScan QTec Xtra measures vibrations in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

RoboVib®

By combining a 3D scanning vibrometer and an industrial robot, RoboVib® forms an automated test station for measuring everything from complex components to complete vehicle bodies. Reduce testing time and expenses as well as time to market significantly in experimental modal analysis. Conduct comprehensive 360° testing of a vehicle body, for example, within only one-two days and overnight instead of weeks of preparation with conventional test setups.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters—get in touch with us today.