Haptics, haptic feedback and display development & testing

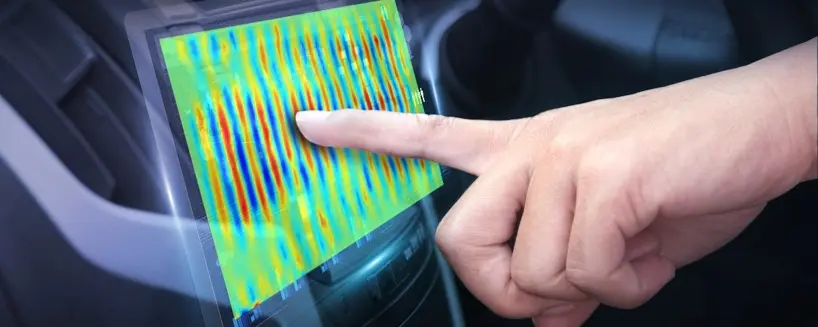

With the success of smartphones, touchscreen technology using haptic feedback has become mainstream. Innovative user interface concepts go a step further and use haptic or vibrotactile feedback in order to give touchscreens a unique feel and user experience. Haptic feedback can make operation significantly easier and more intuitive, for instance, by letting the user know through haptic feedback which virtual button is under their finger or whether it was successfully activated. Laser vibrometers provide non-contact haptics testing solutions for the continuing research, development and quality control of haptic feedback, haptic displays and other haptic devices based on vibration, ultrasound or surface waves.

Polytec Magazine

Laser vibrometry visualizing haptic feedback

The smartphone has shown that buttons can be replaced without sacrificing comfort. The freely configurable display with gesture control has made it even easier to switch between applications. Hap2U drives …

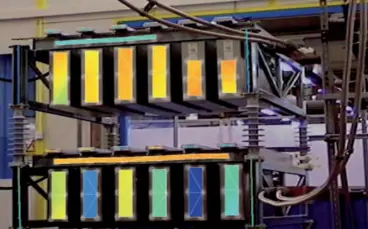

How shear shock waves influence perception

Haptic holography or mid-air haptics promises to bring virtual reality to life, but a new study reveals a surprising physical obstacle that will need to be overcome. A research team at UC Santa Barbara has…

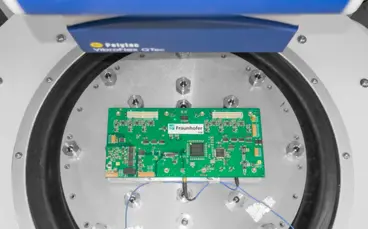

Laser vibrometer based acoustic performance evaluation from -40° to 85°C

The increase of touchscreen interfaces in automotive applications leads to a visual overload of information that has serious safety implications. Haptic feedback technology is seen as an opportunity to imp…

Typical haptic applications and technologies

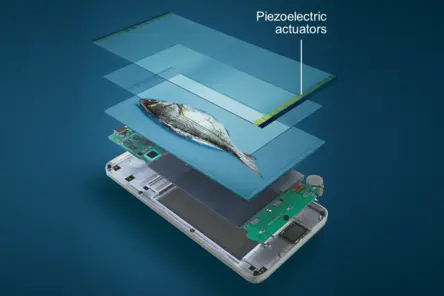

The adoption of haptic interfaces in consumer electronics as well as in automotive applications has seen rapid growth, also giving a boost to developing haptic technologies which feature novel capabilities like localized haptic feedback for surface haptic devices and mid-air haptics. With surface-haptics, which is most commonly employed, haptic feedback is transmitted by a surface, e.g. a virtual button on a touchscreen which upon pressing creates a haptic cue in form of a vibration signal. The second, but less known field of mid-air haptics generates haptic sensations in free space which has the potential to revolutionize immersive experience in virtual reality applications. Most technologies – surface-based and mid-air haptics alike – use either low frequency mechanical vibrations (vibrotactile motion) or ultrasonic vibrations for direct generation of the haptic feedback or energy transmission from the actuator to the target location.

Visualizing haptics

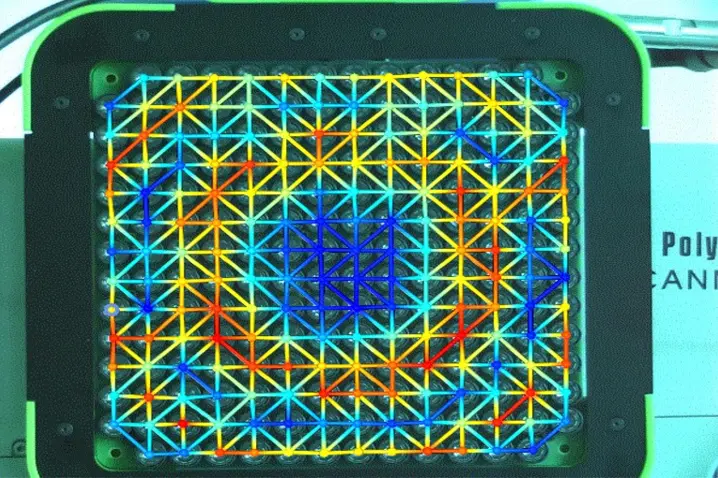

The haptic feedback needs to be quantified and localized for haptics performance verification and FE model validation of haptics devices. For haptics transducer array characterization and for mid-air sound-field characterization, also known as refractro vibrometry, use non-contact vibration measurement solutions. Visualize relevant haptic feedback technologies for comprehensive characterization of your haptic devices.

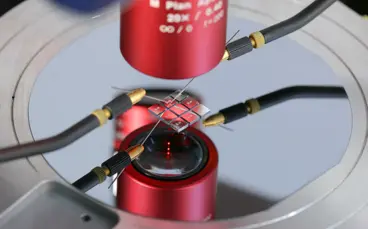

Laser vibrometers are instruments for non-contact haptics testing based on laser interferometry commonly used in R&D and quality control throughout all kinds of industries. Laser vibrometers are perfect for haptic testing precisely characterizing the dynamics of haptic devices. By measuring non-contact they avoid any mass-loading onto a sample end hence capture the true and undisturbed sample motion and haptic feedback. For haptic technologies based on ultrasound, laser vibrometers easily cover the typically operating frequencies of tens of kHz. The µm-sized laser spot size leads to a high spatial resolution, which allows resolving short wavelengths of ultrasonic wavefields.

Mid-air-sound-field visualization or measurement service needed?

Laser vibrometers as haptics testing solution

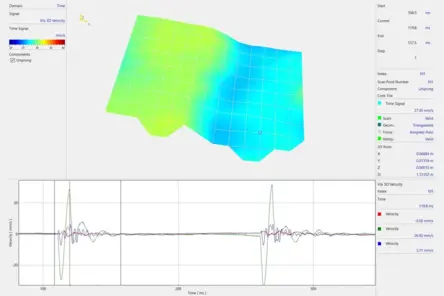

Both 1D and 3D motion data gathered in a non-intrusive way using laser vibrometers precisely describe the in-plane and out-of-plane vector components enabling a full characterization and visualization of the haptic signature at R&D stage. In production testing, laser vibrometers from Polytec help assure the desired haptic feel reliably and with laser precision. See the measurement setup of a haptic panel mounted vertically in front of a 3D laser Scanning Vibrometer and a second vibrometer mounted above the haptic panel capturing the actuator’s motion through a small opening in the housing as phase reference. The resulting measurement data shows the time traces for the selected measurement point on the haptics panel. Three time traces are displayed for x, y and z directions independently.

Why use haptic feedback in your HMI?

Haptic feedback makes users comprehend functions and commands by giving a haptic cue removing the need to look on a display or control panel. This haptic feedback is generated by actuators or transducers and acts as an information carrier. Advanced haptic technologies can also reproduce the feel of physical texture on screens in real-time, creating deep, immersive experiences. One of the innovators in the field of haptic display development and using haptics for enhanced user experiences and control panels is Hap2U.

Related products

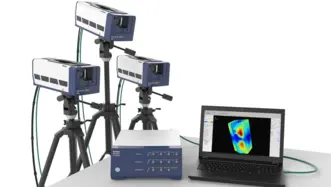

VibroScan QTec Xtra 3D

VibroScan QTec Xtra 3D measures vibrations triaxially in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra 3D ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

VibroFlex

With the modular laser vibrometer VibroFlex, Polytec presents the superior flexibility in optical vibration measurement with a modular sensor solution up to 24 MHz that adapts to your needs: Add microscope objectives for observing tiny structures or measure large samples like machinery or motors from a safe distance. Discover acoustics and vibration phenomena in research and product development for a faster time-to-market or use it for reliable in-line inspections. Learn about how the patented multi-path interferometry QTec® provides an always stable signal level, 20 dB better SNR for faster and clearer results without post-processing.

Measurement service & rentals

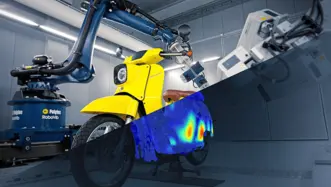

Our engineering services cover a wide range of applications, either onsite or in our laboratories. Ask for our PolyXperts, rent cutting edge laser measurement equipment and benefit from individual support for your projects. Our experienced application engineers are pleased to help, measure and test for you. For comprehensive studies, rent the RoboVib® Structural Test Station

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters—get in touch with us today.