Conducting extensive and precise micromechanics analyses

The possibility to directly integrate microscopic, mechanical functional units with semiconductor electronics at silicon level gave rise to a multitude of different micromechanical sensors and actuators and to the huge success of MEMS and microstructures. The sheer range of product types and areas of use is huge.

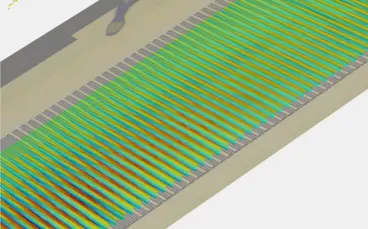

The variety of device type encompasses pressure and inertial sensor systems for automotive and aerospace applications, MEMS microphones, MEMS acceleration and gyroscope sensors for portable electronic devices, a wide range of micro mirror elements for light manipulation, energy harvesters for autonomous systems and microbalances for extremely small material quantities. And, lastly, there are pMUTs and cMUTs for generating ultrasonics in medical technology and micro-acoustic elements such as SAWs, which are increasingly being put to use as electronic filter elements, but are also deployed in lab-on-a-chip applications too.

Capturing both in-plane and out-of plane motions

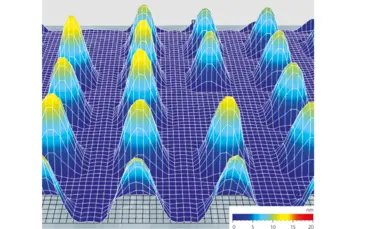

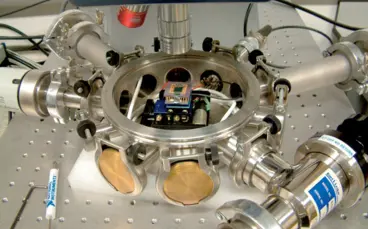

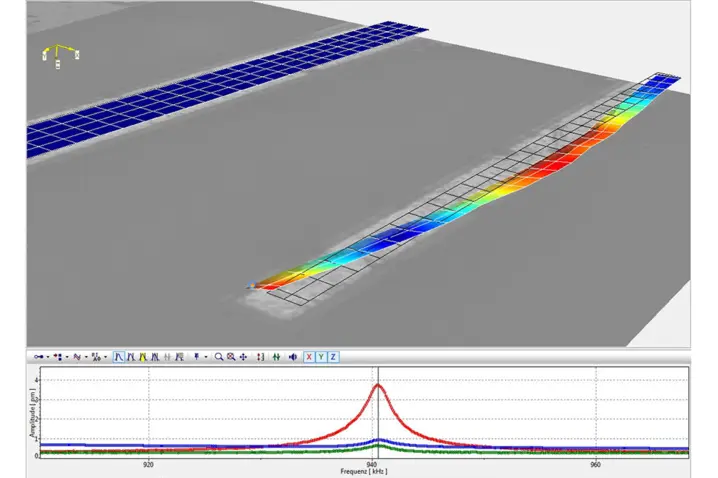

Reliable and precise measurement of not only the electrical measuring technology, but also the direct mechanical function – in other words, the movement of the smallest silicon components – is absolutely essential to developing MEMS components such as this. Using the microscope based single-point or scanning vibrometers from Polytec, you can measure displacements in the pm range, and acquire transfer functions and operational deflection shapes in either 1D or 3D, with a high frequency bandwidth and lateral resolution in the µm or sub-µm range. You also have the option of capturing your microsystem’s topography with the MSA Micro System Analyzer. The MSA-100-3D Micro System Analyzer allows for a real 3D vibration measurement with pm path resolution for both out-of-plane (OOP) and in-plane (IP) components. Here, this is taking place on an MEMS cantilever.

Microstructure characterization

Related products and service

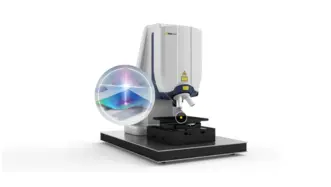

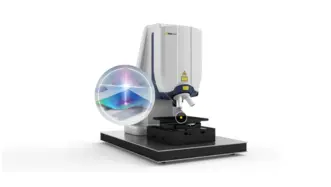

MSA-600 Micro System Analyzer

The all-in-one optical measurement solution for static and dynamic 3D characterization of MEMS and microstructures- now for up to 8 GHz! The MSA-600 enhances microsystem development and quality inspections - also allowing testing on wafer-level when integrated into commercially available probe stations.

MSA-100-3D Micro System Analyzer

The 3D Micro System Analyzer records vibration components in all three spatial directions at once. The optical measurement system enables high-resolution 3D vibration analysis from DC up to 25 MHz with amplitude resolutions in the sub-picometer range, for both in-plane and out-of-plane vibration components.

MSA-060 Micro System Analyzer

Use the MSA-060 for entering the world of microsystem analysis. Record and visualize vibrations and dynamics of small components and microsystems with laser precision over an entire surface from DC to 24 MHz. Micro System Analyzers use measurement lasers, revealing the true dynamics of small components in a completely non-contact and non-invasive way.

MSA-650 IRIS Micro System Analyzer

The innovative and patented MSA-650 IRIS Micro System Analyzer with IR capability allows for measuring true MEMS dynamics up to 25 MHz by characterizing both in-plane and out-of-plane motions through silicon encapsulation without contact, without need for preparing nor decapping the device.

MSA IRIS measurement service

This brand new, patented measurement technology allows for comprehensive and representative analysis of Si encapsulated MEMS, measuring dynamics right through silicon caps. Our PolyXperts are looking forward to receiving your capped MEMS samples for modal testing, feasibility studies and consulting throughout all phases from development over prototyping to manufacturing of your encapsulated microstructures.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters—get in touch with us today.