MEMS characterization for Biology and Medicine

MEMS and microstructures are key basic and cross-sectional technologies for an extremely wide range of medical and biological applications. The scope of use ranges from lab-on-a-chip applications with high-frequency surface waves for rapid medical diagnostics, to MEMS microphones for use in hearing aids, and ultrasonic transducers for medical imaging based on microsystems technology.

You can rely on the non-contact, microscope-based optical measuring technology from Polytec to determine the surface topography and dynamic properties of medical MEMS sensors and actuators. Microscope-based vibration measurement is also used in bionically inspired “technology transfer” from natural to technical systems to measure the biomechanics of insects’ hearing, for example.

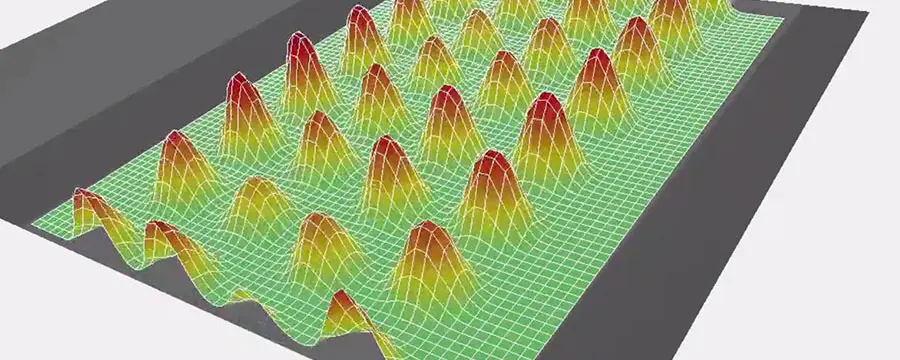

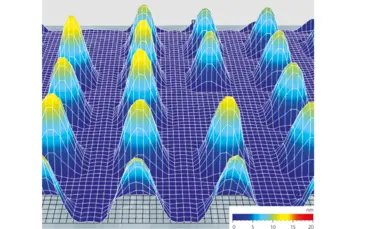

Medical imaging, sonography and intravascular ultrasound applications

Micromachined ultrasonic transducers (pMUTs & cMUTs) are pushing the boundaries of real-time 3D medical imaging (sonography) in applications such as IVUS (intravascular ultrasound) and echocardiography. To characterize the micromechanics of these transducer elements, measurements must be performed at high frequencies (~10 MHz) and with a high spatial resolution (<1 μm). The various possibilities offered by Polytec’s Micro System Analyzer provide this information for pMUT and cMUT development with maximum precision and zero contact.

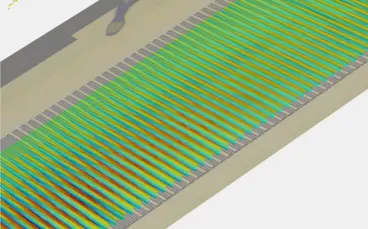

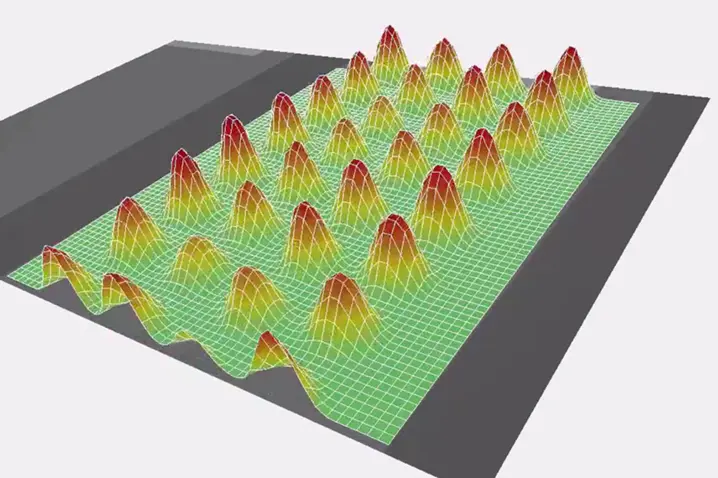

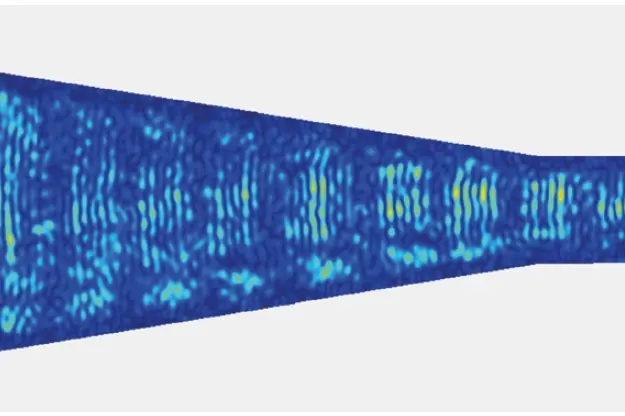

Development of phononic surface acoustic wave devices

Phononic surface acoustic wave devices have shown great potential for enabling integrated point-of-care diagnostics, using the mechanical energy carried by sound to manipulate liquid samples from patients on low-cost microchips. Reserachers have demonstrated the detection of malaria [Reboud J. et al., PNAS, 2012, 15162-7] from the volume of a fingerprick of blood using an acoustic filter. Laser vibrometry is an essential tool of the development process that permits the visualization of true vibrations on the surface across the entire microchips, thus validating our designs. In the future, more complex assays will be integrated on the platform to detect diseases such as tuberculosis.

Microstructure characterization

Related products and service

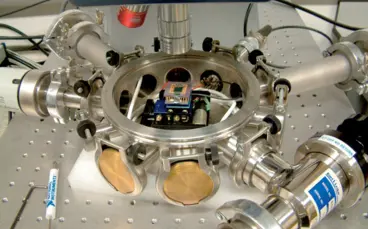

MSA-600 Micro System Analyzer

The all-in-one optical measurement solution for static and dynamic 3D characterization of MEMS and microstructures- now for up to 8 GHz! The MSA-600 enhances microsystem development and quality inspections - also allowing testing on wafer-level when integrated into commercially available probe stations.

MSA-100-3D Micro System Analyzer

The 3D Micro System Analyzer records vibration components in all three spatial directions at once. The optical measurement system enables high-resolution 3D vibration analysis from DC up to 25 MHz with amplitude resolutions in the sub-picometer range, for both in-plane and out-of-plane vibration components.

MSA-060 Micro System Analyzer

Use the MSA-060 for entering the world of microsystem analysis. Record and visualize vibrations and dynamics of small components and microsystems with laser precision over an entire surface from DC to 24 MHz. Micro System Analyzers use measurement lasers, revealing the true dynamics of small components in a completely non-contact and non-invasive way.

MSA-650 IRIS Micro System Analyzer

The innovative and patented MSA-650 IRIS Micro System Analyzer with IR capability allows for measuring true MEMS dynamics up to 25 MHz by characterizing both in-plane and out-of-plane motions through silicon encapsulation without contact, without need for preparing nor decapping the device.

MSA IRIS measurement service

This brand new, patented measurement technology allows for comprehensive and representative analysis of Si encapsulated MEMS, measuring dynamics right through silicon caps. Our PolyXperts are looking forward to receiving your capped MEMS samples for modal testing, feasibility studies and consulting throughout all phases from development over prototyping to manufacturing of your encapsulated microstructures.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters—get in touch with us today.