Characterizing ultrasonic transducers in real time

Ultrasonic transducers produced using microsystems technology are promising for medical ultrasonic applications. Here, you essentially make a distinction between so-called pMUTs and cMUTs (piezoelectric Micromachined Ultrasonic Transducers and capacitive Micromachined Ultrasonic Transducers respectively).

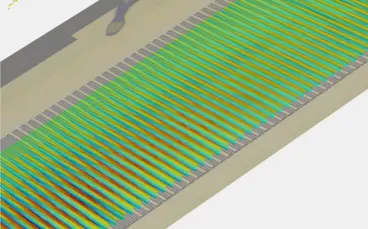

cMUTs have unique properties compared with conventional elements. Thanks to the membrane’s bending mode deflection shape, the transducer’s mechanical impedance reduces, while energy transfer to the ambient medium improves at the same time. Microfabrication also enables affordable series production of cMUTs using semiconductor technology. The semiconductor switching circuit can be directly integrated on the same chip, so as to simply create even large-sized 1D or more complicated 2D array configurations.

Polytec Magazine

FEM simulation and measurement validation of an ultrasound transducer

One of the workhorses of medical imaging is ultrasound imaging, often called (diagnostic) medical sonography. The advancement of transducer technology for creating the ultrasound waves is a very dynamic su…

Non-destructive measurements for determining the performance of a CMUT ultrasound transducer

Fuel consumption of aircrafts is a hot topic in the current discussion about global climate change. An important factor is the design of the aircraft engine itself. In order to reduce weight and build more…

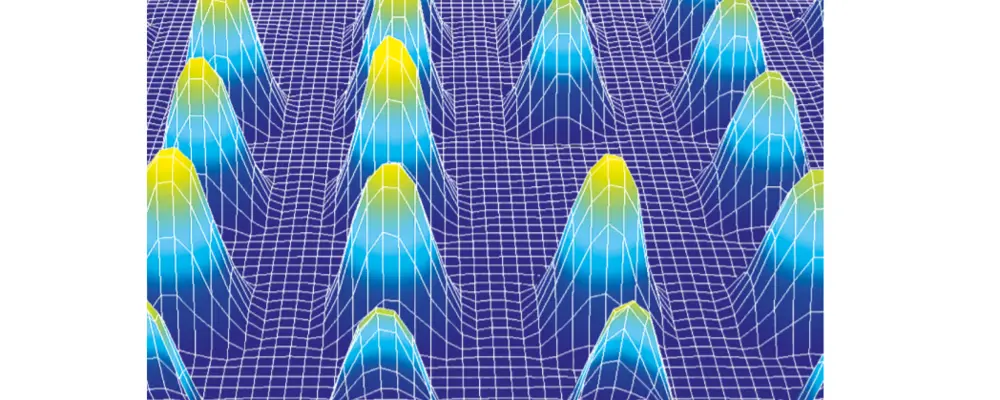

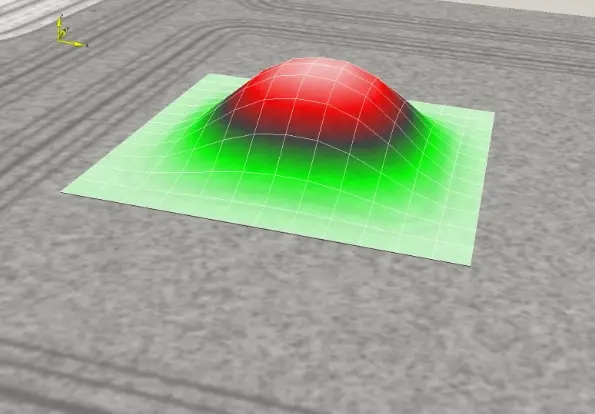

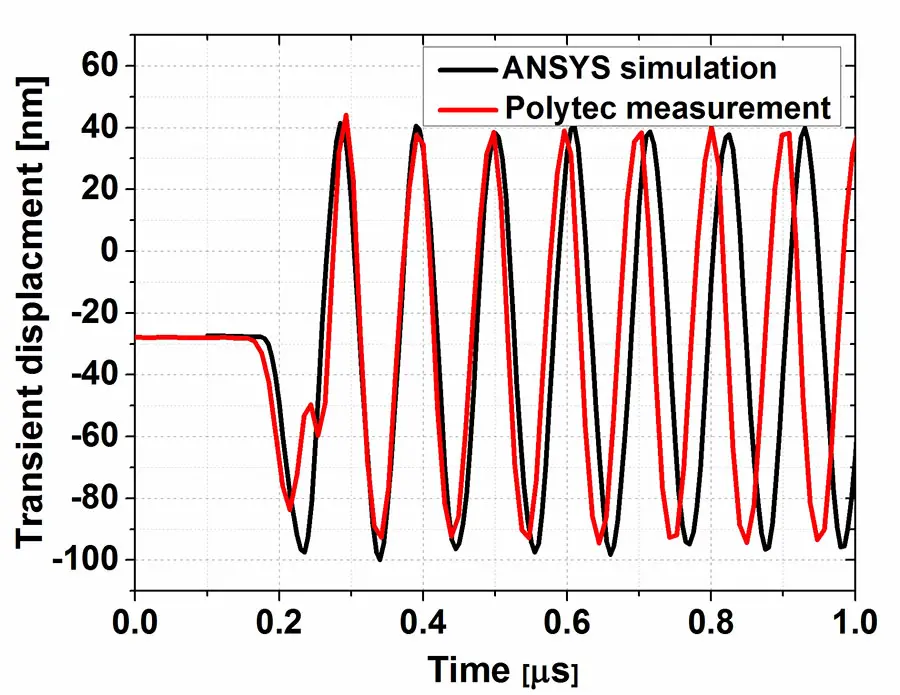

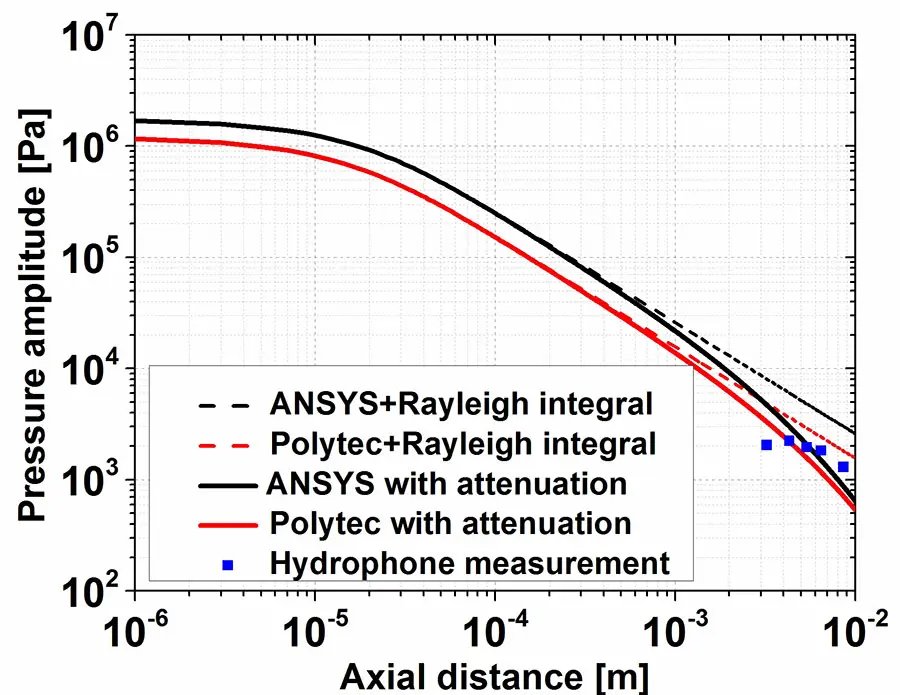

Determining the spatial pressure field on cMUT

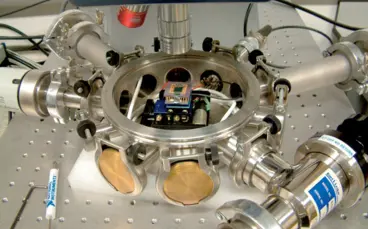

A combination of different methods is often used to characterize new ultrasonic transducers. Finite element simulations predict the transducer’s behaviour, taking the surrounding medium into consideration too. You can then measure new transducer prototypes with microscope-based laser vibrometers such as the Polytec MSA Micro System Analyzer, to directly determine the mechanical frequency response of the sound transducer surface. In doing so, you will come to appreciate the large frequency bandwidth and real time capability that you use to reliably and accurately measure transient processes in particular.

IMEC in Belgium characterized a unique cMUT with the Polytec MSA and, based on the results, determined the spatial pressure field in the transfer medium using the Rayleigh integral method. The results were subsequently confirmed with independent hydrophone measurements.

Microstructure characterization

Related products and service

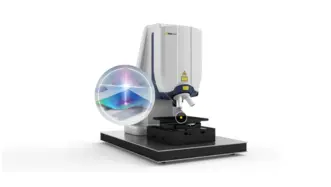

MSA-600 Micro System Analyzer

The all-in-one optical measurement solution for static and dynamic 3D characterization of MEMS and microstructures- now for up to 8 GHz! The MSA-600 enhances microsystem development and quality inspections - also allowing testing on wafer-level when integrated into commercially available probe stations.

MSA-100-3D Micro System Analyzer

The 3D Micro System Analyzer records vibration components in all three spatial directions at once. The optical measurement system enables high-resolution 3D vibration analysis from DC up to 25 MHz with amplitude resolutions in the sub-picometer range, for both in-plane and out-of-plane vibration components.

MSA-060 Micro System Analyzer

Use the MSA-060 for entering the world of microsystem analysis. Record and visualize vibrations and dynamics of small components and microsystems with laser precision over an entire surface from DC to 24 MHz. Micro System Analyzers use measurement lasers, revealing the true dynamics of small components in a completely non-contact and non-invasive way.

MSA-650 IRIS Micro System Analyzer

The innovative and patented MSA-650 IRIS Micro System Analyzer with IR capability allows for measuring true MEMS dynamics up to 25 MHz by characterizing both in-plane and out-of-plane motions through silicon encapsulation without contact, without need for preparing nor decapping the device.

MSA IRIS measurement service

This brand new, patented measurement technology allows for comprehensive and representative analysis of Si encapsulated MEMS, measuring dynamics right through silicon caps. Our PolyXperts are looking forward to receiving your capped MEMS samples for modal testing, feasibility studies and consulting throughout all phases from development over prototyping to manufacturing of your encapsulated microstructures.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters—get in touch with us today.