Non-contact, inline monitoring of length & speed

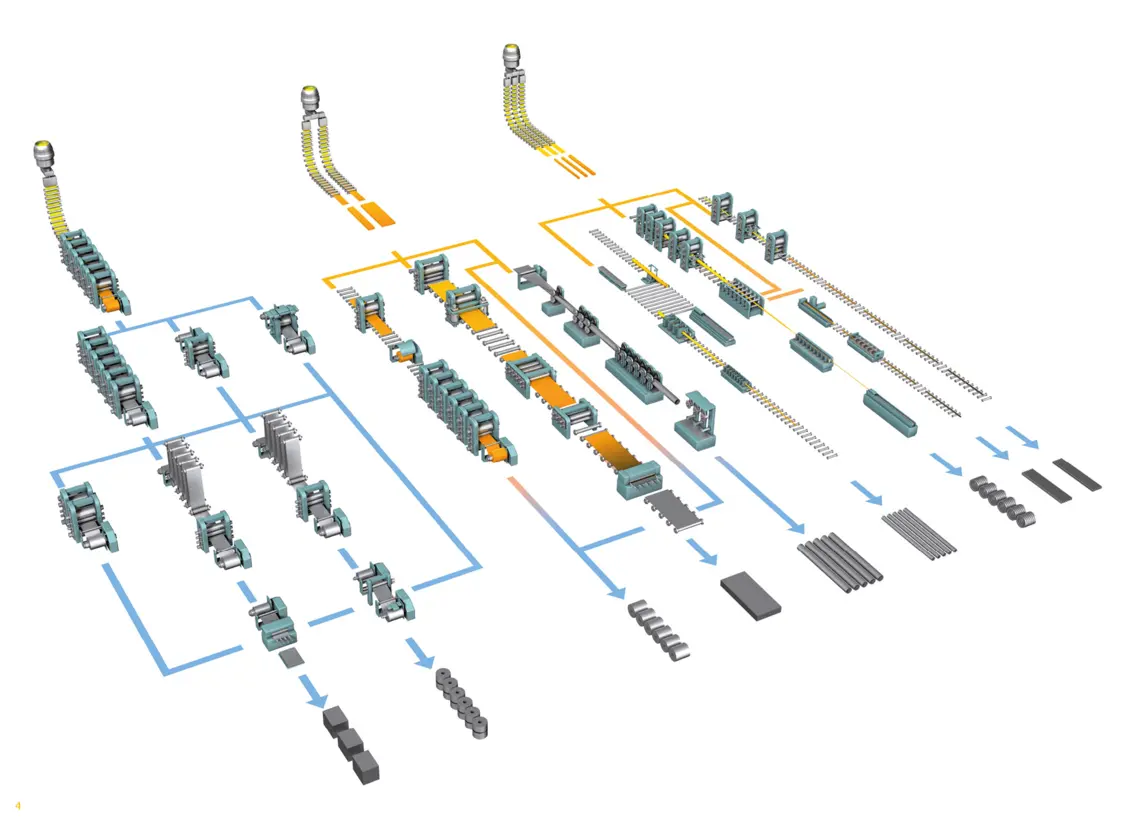

For rolling mills, casting lines, hot and cold applications, coating plants, whether tubes and pipes, long or flat metals, elongation or superior cut-to-length and process control - Contact us today!

Polytec stands as a trusted partner for steel, metal, and aluminum manufacturers, offering exceptional service, including a free 3-year warranty, a 24-hour exchange program, and comprehensive global support.

Downloads

Drivetrain

Sealing surfaces

Electronics

Optics, cameras,

touch display

Fuel injection systems

Shock absorbers

Roping

Efficient process control using ProSpeed® laser speed and length sensors

Climate change is one of the dominating challenges of modern society and industry. Even though steel is one of the worlds most recycled materials, the steel industry remains the largest industrial emitter …

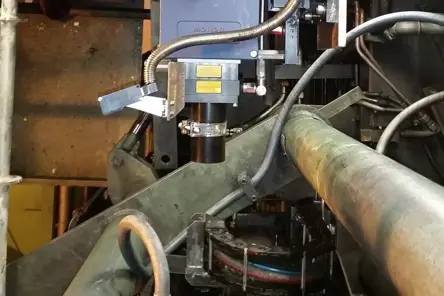

Optical encoders as the reliable measurement system for pipe and tube production

The Polytec LSV laser velocimeter offers process control with utmost precision for the production of flat, round and long products based on laser-precise and repeatable measurement of e.g. tube speed durin…

Controlling the length cutting of the trapezoidal sheet metal profiles

Significantly higher demands are being placed on quality and dimensional stability in the production of premium trapezoidal sheet metal profiles. A wide variety of different profiles and surface properties…

Benefit from ProSpeed® optical sensors

- Non-contact: no slippage, no wear for long-time accuracy

- Large depth-of-field masters varying distances

- Flexibility with up to 3m large stand-off distance

- Laser measures accurately on all materials, also red-hot

Measure length and speed in steel industry without contact

ProSpeed is the reliable sensor technology for the steel, aluminum and metals industry: Whether sheet material or piece good, from length control of cut sheets to speed measurement for the regulation of roll gaps according to the mass flow principle until cut-to-length control in continuous casting.

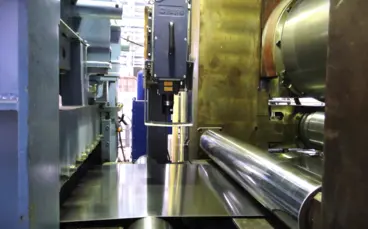

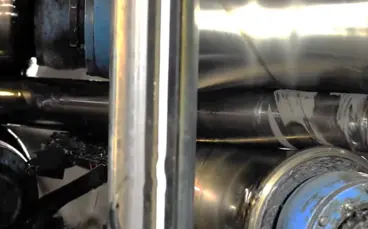

Reliable sensor performance in harsh environments

Non-contact length and speed monitoring with laser precision in steel, aluminum and metals processes is the domain of ProSpeed® LSV laser optical sensors made in Germany. Designed to excel in the toughest environments, whether oily, dusty, or dirty, these sensors provide unmatched performance where traditional methods fail. LSV (short for Laser Surface Velocimeter) provide real-time process data for optimized machining, superior process control, and increased efficiency. No slippage, no wear, no damage to the produced material surface. Just accurate, reliable measurement.

Contact us for custom sensor solutions, featuring adjustable stand-off distance and large depth of field, ensuring maximum flexibility: For hot applications, the umcompromising TPH Thermo-Protective Housing offers additional protection. For challenging environments, Polytec has elaborated a wide range of application-specific accessories, like air wipe, beam deflection, mounting and cooling plates - making any LSV sensor your custom measurement solution.

35 years experience, 3 year warranty have got your back!

With over 35 years of experience in the industry and in laser-optical measurement technology, Polytec has always focused on reliability and accuracy in their length and speed gauges, covering the back of thousands of satisfied industrial customers worldwide.

The included 3-year warranty, the 24-hour sensor exchange program and uncompromising support within the experienced PolyXperts network underline Polytec’s commitment. Read more about Polytec length & speed sensors or the complementing PolyXpert services.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters — get in touch with us today.