Surface topography of optics, glass & transparent materials

Quality and manufacturing productivity of components like lenses, mirrors and optical elements is ensured by measuring form and roughness parameters down to the (sub)nanometer. All this with a high efficiency to safeguard the manufacturing throughput.

Find efficient measurement and testing solutions for quality inspection of optics, glass or other transparent materials within the range of TopMap optical surface metrology. Optical profilers by Polytec are flexible and easy-to-use inspection systems for measuring thickness, determining form parameters like flatness, step-height or parallelism - fast and with nanometer precision.

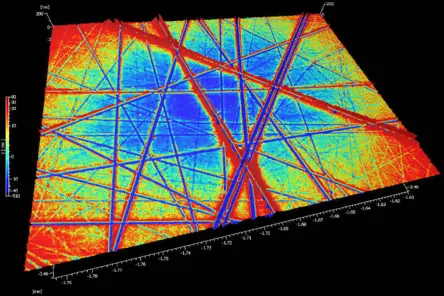

Polytec also offers custom solutions depending on your roughness, distance or thickness requirements. Benefit from high precision with (sub)nanometer resolution data or large area scanning for covering larger samples or even multiple in one shot. Fast measurements meet high repeatability: In-line, on production level and in the lab.

- Measure lenses & mirrors

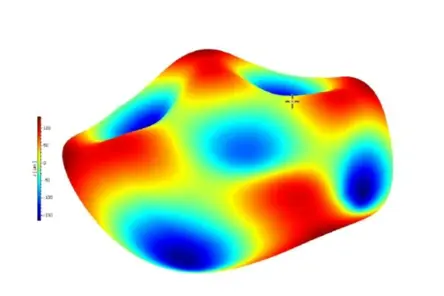

- Design Freeform optics

- Check Diffractive Optical Elements (DOE)

- Inspect laser & optical equipment etc.

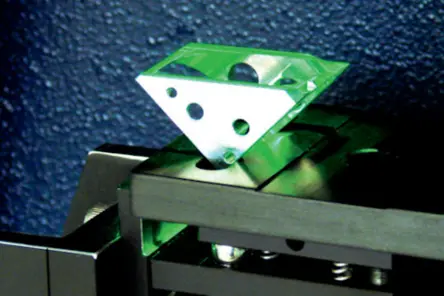

Surface profilers for optical components

Macro Profiler

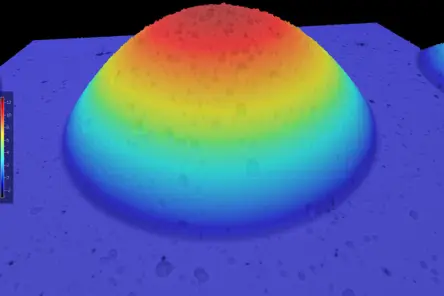

Pro.Surf with its areal topography scanning determines form and flatness faster. Its telecentric optics with large Z range reaches holes and recessed surfaces. The largest FoV and True Stitching handles big samples and multi-sample measurements with ease. Upgrade to Pro.Surf+ and also analyze roughness all-in-one.

Micro Profiler

Micro.View profiler systems are optimized for measurements with sub-nanometer resolution. With focused optics and high vertical resolution they enable detailed analysis of microstructures, surface finish and material distribution where even the smallest deviations matter.

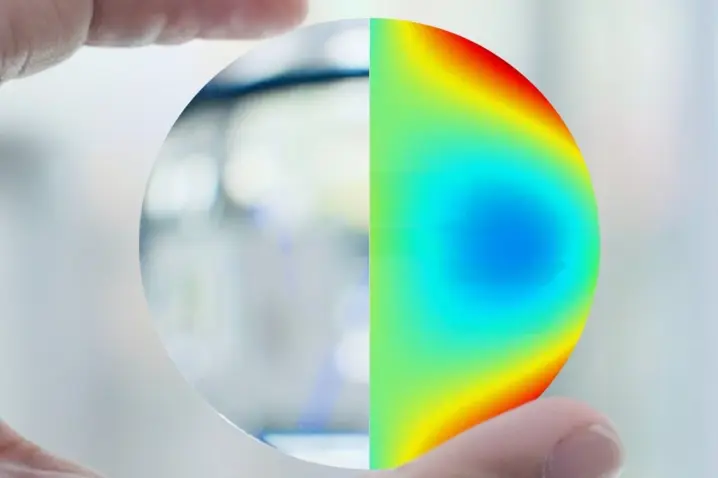

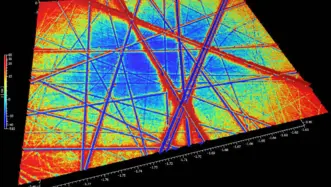

Measure form, flatness & roughness on lenses, optics, mirrors

Measure surface form parameters, evaluate flatness or step-height on optical components, glass and transparent media. TopMap surface profilers allow for complete and fast inspections of lenses, optics, freeform optics or mirrors for design optimization and quality control in manufacturing. Transparent materials such as optics, mirrors, or lenses are challenging materials to measure due to its sensitivity to scratches or defects (tactile measurement) and reflectivity (optical measurement). Prevent from scratches or influences of tactile measurement tips by using non-contact optical measurement technology. The large area topography scanning of Polytec enables capturing entire workpieces or larger areas in one shot. The elaborated SST Smart Scanning Technology also copes with measuring different and challenging surface reflecitivies, providing reliable measurement performance on dull, matt, coated and shiny surfaces.

Typical optics inspection and measurement tasks

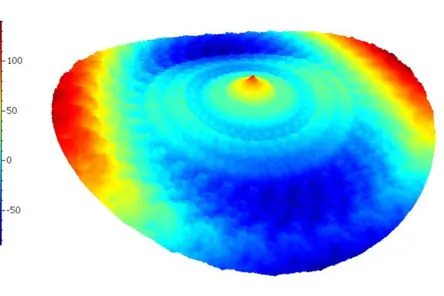

- Flatness measurement of mirrors

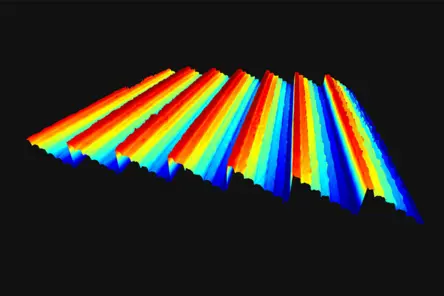

- Complete 3D characterization of lenses and freeform optics

- Warpage measurement on thin films or layers

- Layer thickness measurement

- Separated inspection of form, waviness and texture

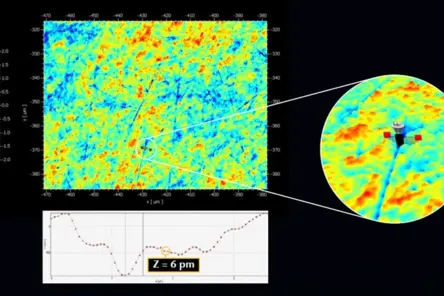

- Roughness and microstructure analysis in sub-nm range

- Defect detection and evaluation related to scratch testing

- Step-height measurement on precision mechanics such as mirror or lens holders

- Form tolerance check of optical precision equipment (lasers, interferometers etc.)

- Combined measurement of Flatness-Thickness-Parallelism of top and bottom surface in one shot

Measurement tasks in the optical industry

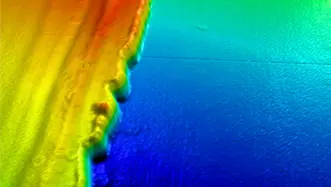

Optical polishing

Superfinished surfaces and optical polishing demand non-contact, areal and high-precision white-light interferometers. Polytec profiler delivers remarkable results even with very reflective or transparent materials.

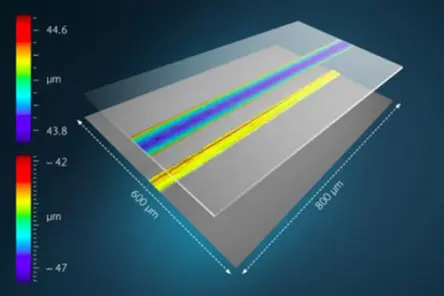

Surface step height

Profilometric step-height measurement delivers objective layer/etch depth and uniformity from areal data, supporting ISO-aligned reporting and production SPC.

Layer thickness

Measure areal surfaces parameters to control layer thickness and optimize coating processes for minimizing quality costs.

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.