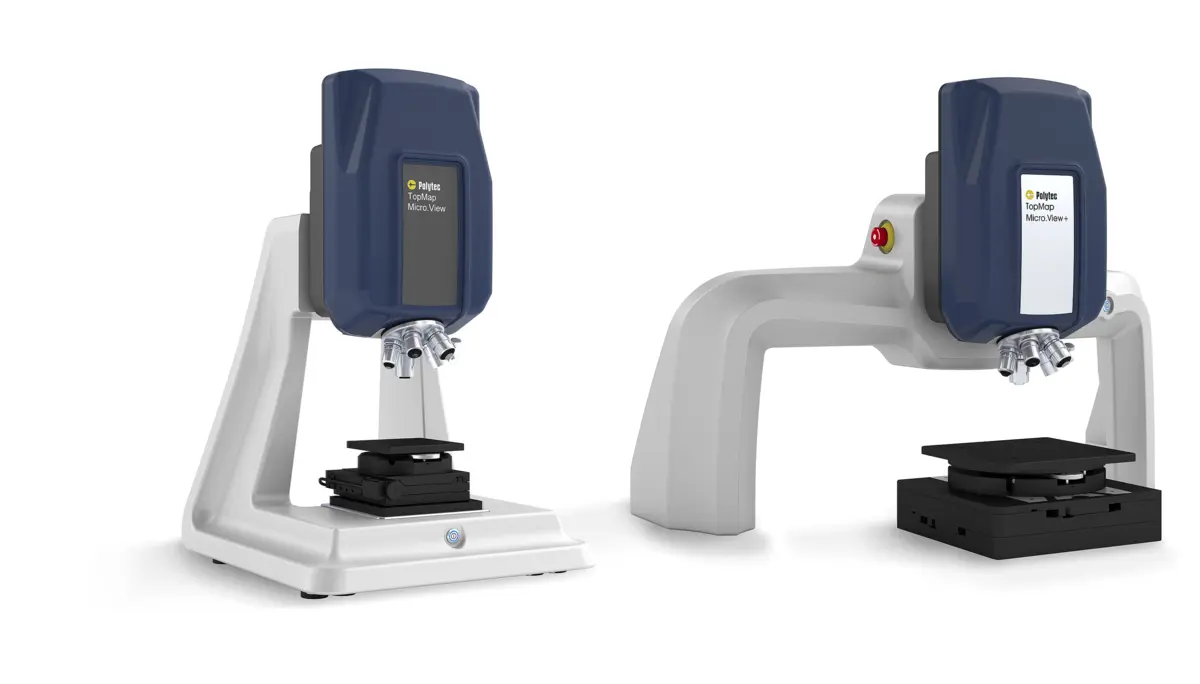

Microscope-based 3D surface profilers.

4 years warranty!

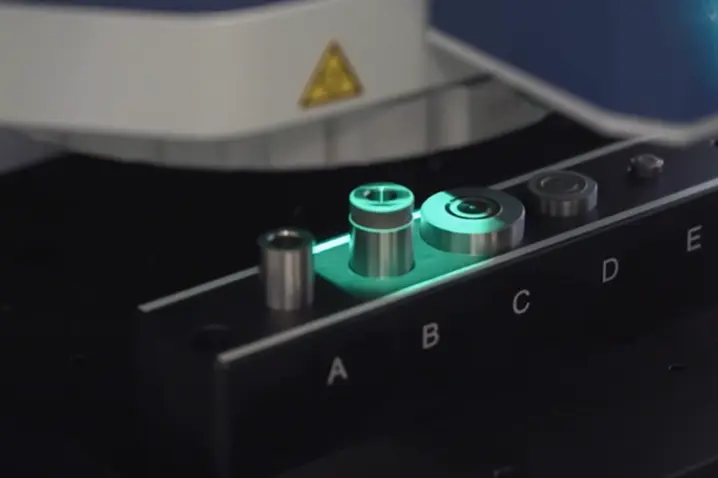

Microscope-based surface profilers are used for high-resolution, non-contact 3D surface metrology when fine details matter. Within this category, the Micro.View family stands out by combining robustness, flexibility and precision—even on challenging materials such as reflective, dark, transparent or mixed surfaces.

The Micro.View family combines optical interferometry with microscope optics to address a wide range of surface metrology tasks:

- High-resolution surface roughness and texture analysis with utmost precision based on CSI Coherence Scanning Interferometry, plus True Stitching

- Repeatable and reliable quality control, with Focus Finder, Focus Tracker and recipe management

- Flexible adaptation to different sample sizes, materials with CST Continuous Scanning Technology, True Stitching and wide range of objectives (0.6X .. 111X)

- In lab and production with patented ECT Environmental Compensation Technology for stable measurements despite influences

The resulting precision, robustness, and flexibility makes Micro.View a great choice for applications include precision engineering, optics and optical components, semiconductor and microelectronics, MEMS and microsystems, materials research, and tribology—in both laboratory and production-oriented environments.

Some key facts

What is the most fitting Micro.View surface profiler?

Micro.View

Compact microscope-based 3D surface profiler for highest precision.

- Cost-effective system

- Wide range of objectives for specific tasks

- Small table-top footprint

- Optional ECT for stable results on shop floor

Best fit for precision manufacturing, R&D labs, development tasks and high-accuracy surface inspection in engineering.

Micro.View+

Adds Color View to the Micro.View profiler. For more insights and the ability to run automated, operator-independent workflows.

- Fully motorized stages with Focus Tracker

- QC recipe management for unattended operation

- Supports large/tall samples (up to 370 mm)

- Color View for enhanced visualization and defect detection

- In- and at-line measurement ability

Best choice if Color View is needed and automation capabilities are important.

Surface profiler - benchmark in technical data

| Feature | Micro.View | Micro.View+ |

|---|---|---|

| Resolution | Sub-nm | Sub-nm |

| True Stitching | Yes | Yes |

| Sample height | Up to 100 mm | Up to 370 mm (with spacer) |

| Stages | Manual & motorized stages (20, 75, 100 mm) Manual & motorized tip/ tilt | Motorized 100 x 100 or 200 x 200 mm stage Automatic tip/ tilt |

| Visualization | 3D height data (inverse rainbow) | 3D height data (inverse rainbow) Color View as hardware option |

| Objectives | 0.6x ..111x (long working distance options) | 0.6x ..111x (long working distance options) |

| Automation | Measurement recipes Positioning Advanced Focus Finder | Measurement recipe Positioning Advanced Focus Finder Motorized (or manual) turret Closed Loop /w Focus Tracker Head only line integration |

| Learn more | Details about Micro.View | Details about Micro.View+ |

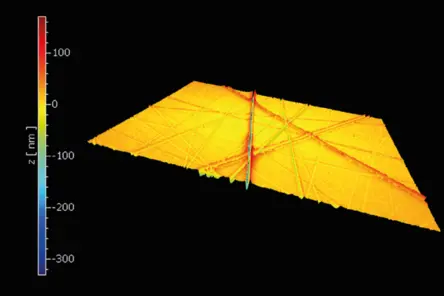

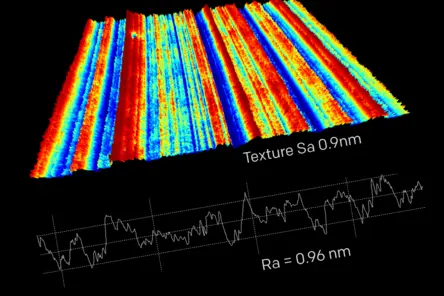

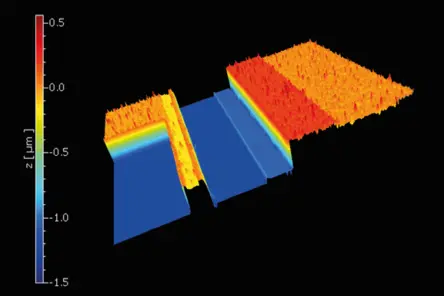

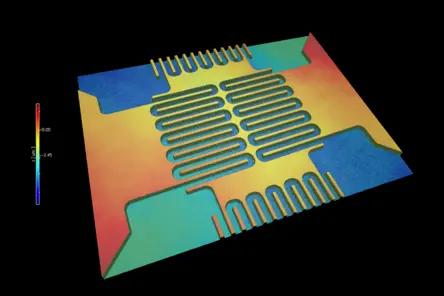

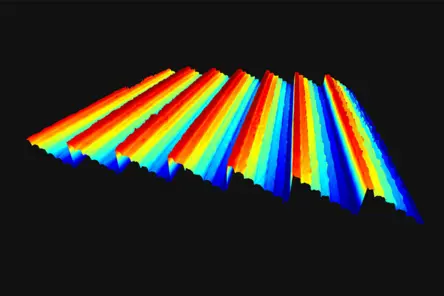

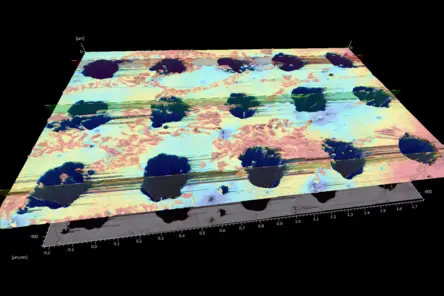

Surface profile analysis of roughness and texture for precision engineering, optics, and microsystems

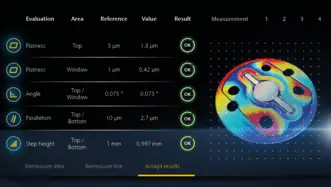

Below are real-life results from standard 3D surface profiling tasks—roughness, flatness, step height, texture and tribology—on typical engineering materials. These examples come from our application centers, which run feasibility studies and contract measurements for customers.

Choose the right surface profiler with confidence—get a demonstration of our capabilities.

Embedded features for high precision and efficient workflows—even in harsh environments

The feature set of our microscope-based 3D optical surface profilers are designed to measure precision components and fine surface details - whether in the lab or production:

- CSI Coherence Scanning Interferometer for utmost precision

- Reliable surface roughness analysis in sub-nm precision on rough and shiny surfaces with SST Smart Scanning Technology

- Widest and most variable FoV for flexible roughness analysis (from 0,07 mm bis zu 15,5 x 11,7 mm)

- True Stitching for unmatched accuracy of wider parts

- Wide Z measurement range of 100mm with full resolution due to Continuous Scanning Technology (CST)

- Recipe-driven measurement with Focus Finder for repetitive operations

- Compliant to newest standards (ISO 21920, ISO 25178 and more)

- Operator-independent workflows with motorized XYZ, tip/tilt, encoded turret and Focus Tracker

- Ready for full-automation by tight integration with modular design and interfaces

The resulting precision, robustness, and flexibility makes Micro.View ideal for teams who need traceable, repeatable 3D surface data without complicated setup or environmental constraints.

Feasibility study?

Send us your sample and we'll run a feasibility study with our profiler and walk with you through the results.

This gives you a precise understanding of the optical profiler’s performance on your actual samples.

Related information

Differences in Micro.View and Pro.Surf+ roughness profiler

While Micro.View also supports form, flatness and step height measurements, its core strength lies in high-resolution 3D surface roughness and texture analysis.

The Pro.Surf+ has the reverse approach. Strength is flatness, parallelism and form inspection but also can run surface roughness analysis with a lateral resolution of 2.6 µm.

Measurement tasks

With a WLI optical profiler you can handle all the surface measurement tasks - from surface form parameters, roughness and specific tasks as thickness of layers and coatings.

White light interferometer

Introduction of the white light interferometry technology and the benefits for non-contact areal surface measurement.

"Try before buy" offer

Measure, rent, decide - on your terms. Make a confident decision about which surface profiler fits into your metrology strategy and safeguard your capital investment.

Discuss your demands with our experts

Let’s start with a short discussion about your parts, tolerances, and workflow — and, if useful, we can add a feasibility study, PolyMeasure (contract measurements), or a PolyRent trial as optional next steps.