Quality inspection for thick-wire bonding

Thick-wire aluminum bonds, which are widely used in the automotive industry to bond power semiconductors, need to be extremely reliable. Laser vibrometers allow you to examine the bond process in situ and are therefore critical in helping you to clarify any quality defects.

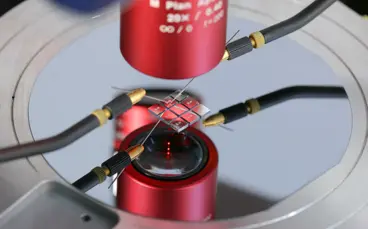

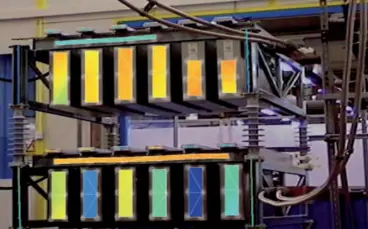

Microelectronic assemblies – where the transmission of high output levels and currents is paramount (for example power modules in the automotive industry,) – are widely processed for electric bonding purposes using so-called thick-wire bonds. The electrical contacts are made using the ultrasonic friction welding process with aluminum wires with diameters ranging from 100 to 600 μm. Resonation of the bond pads, which could well lead to a lower-quality bond connection with questionable long-term reliability, is undesirable in this regard.

Fiber-optic vibrometry is a great way of both analyzing the pads’ vibrations with maximum precision and assessing the bond quality during the bond process. Laser vibrometry combines the advantages offered by a non-contact measurement solution that doesn’t influence the sample’s vibration behavior with the benefits of a sufficiently high level of temporal and spatial resolution.

Laser vibrometry focusing on the small details

Characterize small and delicate structures in a non-contact way. Analyze vibration, acoustics and dynamics. Measure biomedical samples, electronics components and microstructures like MEMS by light, without mass-loading, and from DC up to the GHz range on a large bandwidth. Laser vibrometers focus on the small details, measuring deflection shapes for model validation. They assess the frequency response and determine resonance frequency, impulse response and Q factor. No matter how big or small – Polytec vibrometers measure it!

Related products

VibroFlex

With the modular laser vibrometer VibroFlex, Polytec presents the superior flexibility in optical vibration measurement with a modular sensor solution up to 24 MHz that adapts to your needs: Add microscope objectives for observing tiny structures or measure large samples like machinery or motors from a safe distance. Discover acoustics and vibration phenomena in research and product development for a faster time-to-market or use it for reliable in-line inspections. Learn about how the patented multi-path interferometry QTec® provides an always stable signal level, 20 dB better SNR for faster and clearer results without post-processing.

VibroOne

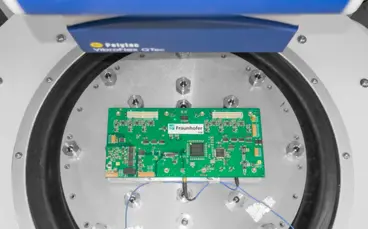

The laser Doppler vibrometer VibroOne® is the one-box solution for non-contact vibration measurement up to 3 MHz. It is specifically designed for tightly packed setups, whether in research laboratories, challenging production environments or for non-contact analysis of tiny details on microstructures or biomedical probes. The optional inline HD+ camera helps positioning the laser precisely and provides proper test documentation.

IVS-500 Industrial Vibration Sensor

The IVS-500 Industrial Vibration Sensor is key to fast and non-contact vibro-acoustic quality inspection, structure-borne noise analysis and reliable pass-fail decisions. Its robust and compact design enables a smooth integration into process control systems for in-line and production testing up to 100 kHz, whenever requiring short cycle times like for end-of-line tests. The sensor is wear-free and avoids expensive servo-mechanisms or noise protection cabins.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters—get in touch with us today.