Control of shakers in vibration and fatigue testing

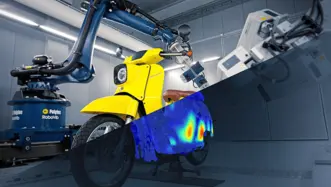

The precise control of shakers plays a decisive role in modern vibration testing and fatigue testing. Polytec's VibroFlex QTec laser vibrometer revolutionises this process with its patented QTec® multi-channel interferometry technology.

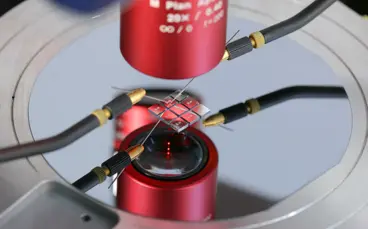

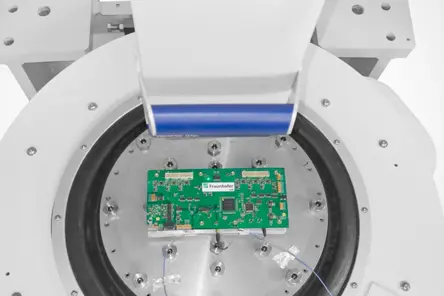

The VibroFlex QTec laser vibrometer enables direct measurement at any point on the component and precisely captures the vibration response for accurate amplitude, frequency and phase measurement on the test specimen. The limitations of other measurement solutions such as accelerometers in terms of positioning and mass loading can thus be overcome. QTec laser vibrometry is particularly advantageous for electronic components with sensitive components such as integrated sensor modules.

Advantages of the VibroFlex QTec:

- Non-contact: always optimum position for control signal

- Simple: no surface treatment of the sample required

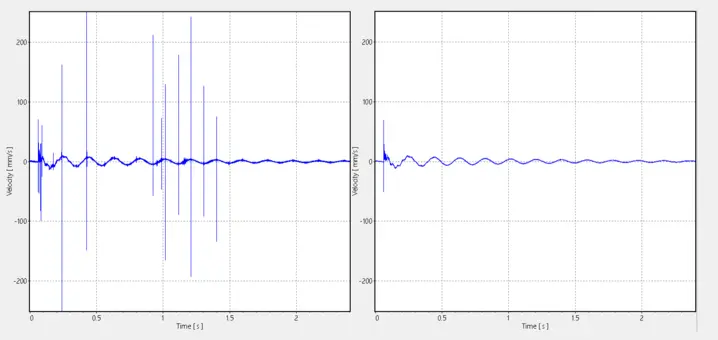

- QTec®: no drop-outs or signal loss

- Precise: high amplitude resolution

- Flexible: high frequency and dynamic range

Versatile application possibilities

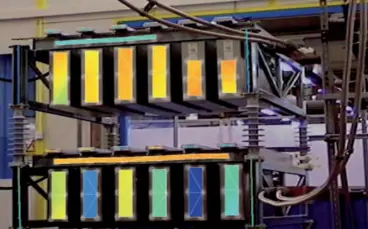

The VibroFlex QTec is ideally suited for various areas of application such as the automotive industry (vibration tests for sensors and electronics), electronics and semiconductors (testing of printed circuit boards and sensitive components) and the solar industry (vibration analyses for robust solar modules).

Thanks to its flexibility, precision and reliability, the VibroFlex QTec sets new standards in shaker control and vibration testing. It offers an optimal solution for demanding test scenarios where conventional methods reach their limits.

Advantages of the laser vibrometer compared to accelerometers

- Measurement at any point

- Unlike accelerometers, which are often attached to the shaker fixture, the laser vibrometer can measure at any point on the fixture or even directly on sensitive components.

- No falsification of the results

- Accelerometers can falsify the vibration response, especially on small structures. The laser vibrometer provides non-contact real-time data.

- More precise control

- As the laser vibrometer records the vibration directly where the corresponding amplitude, phase and frequency are present, ideal shaker control is achieved.

QTec® technology

Drop-out safe, high-resolution, fast and where necessary

The innovative QTec multi-channel technology guarantees stable signals without drop-outs. Parallel scanning from different perspectives eliminates disruptive drop-outs, which protects the control system and the shaker from damage.

Related products

VibroFlex QTec

With the modular laser vibrometer VibroFlex, Polytec introduces the new flexibility in optical vibration measurement up to 24 MHz: Measure noise, vibration, harshness (NVH) with highest signal quality and resolution or from large and>500 m distant samples like machinery, motors etc. Choose from different sensor heads, accessories and change configurations tailored to your individual measurement task.

Measurement service & rentals

Our engineering services cover a wide range of applications, either onsite or in our laboratories. Ask for our PolyXperts, rent cutting edge laser measurement equipment and benefit from individual support for your projects. Our experienced application engineers are pleased to help, measure and test for you. For comprehensive studies, rent the RoboVib® Structural Test Station

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters—get in touch with us today.