Experimental modal analysis simplified

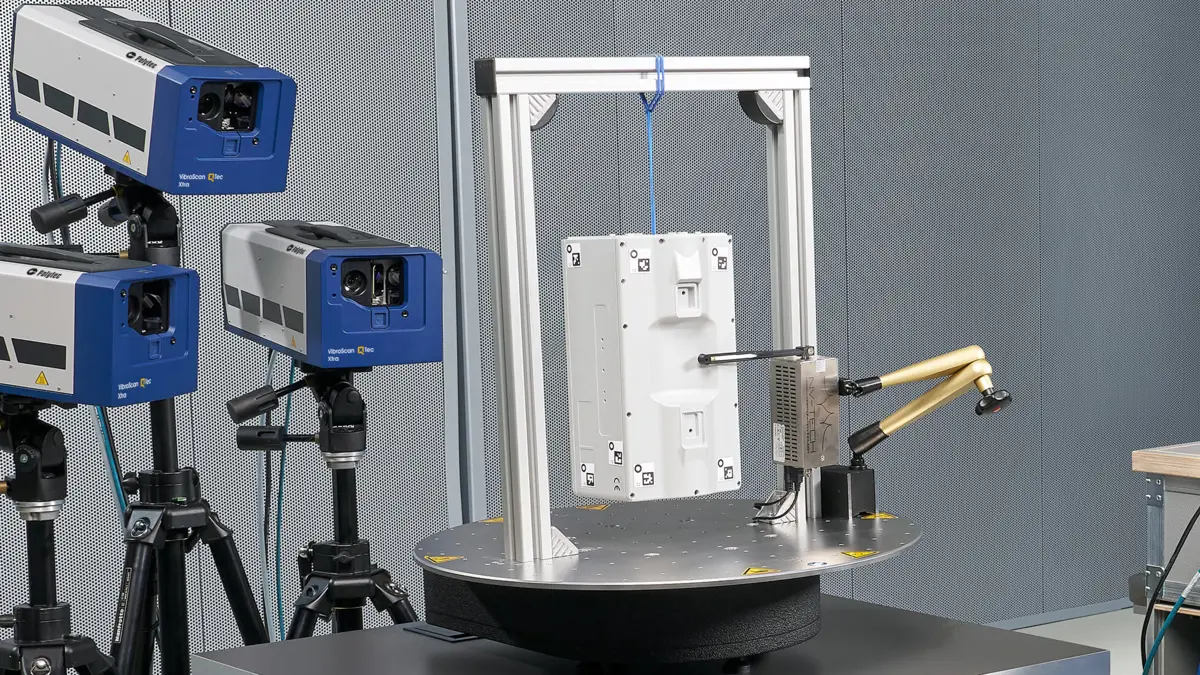

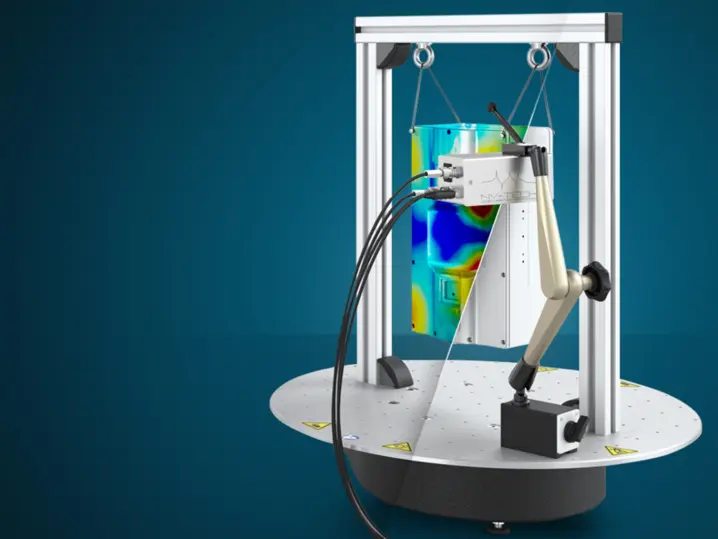

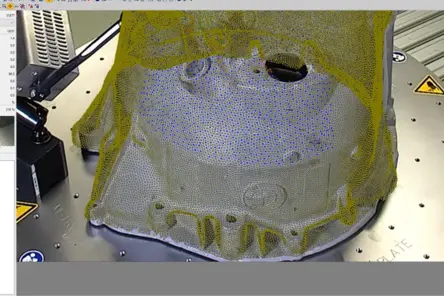

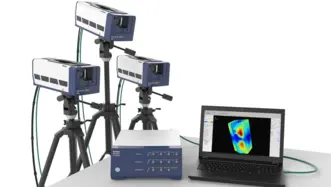

RoboVib® Bench enables automated and full-body experimental modal analysis using Polytec’s optical 3D scanning laser vibrometers. Its easy to set-up hardware and software integrates seamlessly into the Polytec scanning vibration measurement workflow and saves time by automatically repositioning the devices-under-test (DUT) instead of a manual and tedious relocation of the sensor setup. 360° measurements of the DUT are as easy as a measurement from just one side.

Get in touch with our experts

Get in touch with our experts

Let’s talk! We will find the right solution for your needs.

Highlights

//- RoboVib® Bench automated modal test station

- Integrates into the CAE workflow

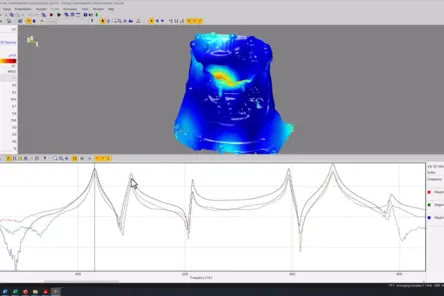

- Creates full-body 3D vibration data set

- Small footprint for lab use

- Accepts part up to 50 kg (110 lb)

- Interfaces with PSV software

- Ready to use – no installation

Automating your modal test

A small footprint and individual positioning of all components enables operation in the lab for small and medium-sized DUTs up to 50 kg (110 lb). RoboVib® Bench converts a scanning vibrometer measurement into a software defined test using test geometries from CAE and returning a completed modal data-set and – on demand – an updated geometry of the DUT. A breadboard-style magnetic steel baseplate allows for safe mounting of the DUT and individual instrumentation with automatic modal hammers or inertial shakers.

RoboVib® Bench enables test engineers and technicians to carry out automated modal tests with the highest spatial resolution without having to meet special safety requirements, as is the case with conventional robotic systems. The product is particularly suitable for smaller test objects, such as control units or gearbox housings, and offers an efficient solution for acoustic optimization.

RoboVib® Bench – Optical test station for automating experimental modal analysis

Downloads

Related products

VibroScan QTec Xtra 3D

VibroScan QTec Xtra 3D measures vibrations triaxially in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra 3D ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

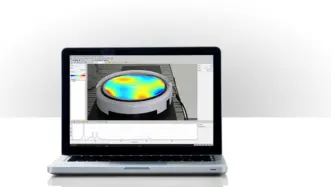

PSV Software

The PSV Software is the heart of every Polytec full-field vibration measurement system. This comprehensive software package allows the fast and simple acquisition, display and editing of vibration measurement data gathered with all VibroScan QTec Scanning Vibrometers, the MSA Micro System Analyzer series for microscopic observations or the automated structural test station RoboVib®.

RoboVib®

By combining a 3D scanning vibrometer and an industrial robot, RoboVib® forms an automated test station for measuring everything from complex components to complete vehicle bodies. Reduce testing time and expenses as well as time to market significantly in experimental modal analysis. Conduct comprehensive 360° testing of a vehicle body, for example, within only one-two days and overnight instead of weeks of preparation with conventional test setups.

No budget? Just measure.

Whether you need contract measurements, equipment rental, or leasing, our scalable services deliver precise data—without the overhead of major investments. Ideal for short-term projects, occasional use, or limited budgets.

With PolyFlex you get results without compromising timelines or budgets.