Determining material parameters in a non-destructive way

Material properties are determined with zero contact using laser vibrometers. Conclusions can be drawn as to a material sample’s strength by determining the resonance frequency during broadband excitation. This method is used to ensure quality when manufacturing different building materials, since it is completely non-destructive. Often expensive test objects can be saved, and it can also be easily automated.

Construction material requiring non-invasive testing

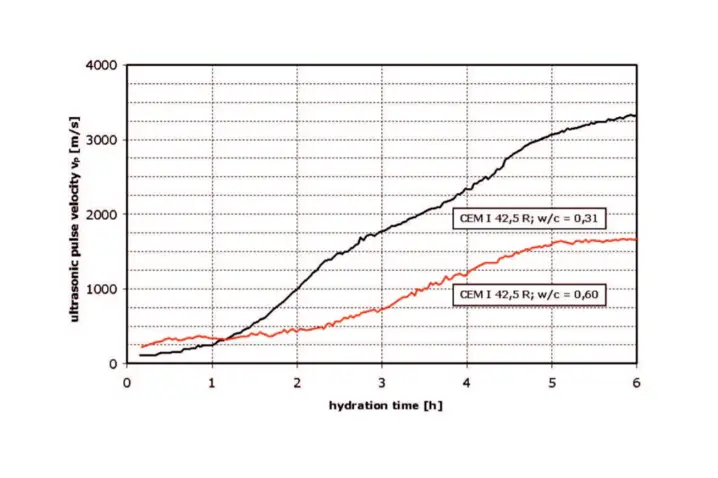

Knowledge of the temporal and local changes to the material properties of cement-bonded systems is vitally important for both materials research and for planning and implementing construction projects. The material properties can be described using ultrasound parameters. Cement-bonded building materials have a high ultrasonic wave absorption capacity straight after mixing, as well as a low sound velocity. Depending on how structure development progresses, the sound velocities and signal amplitudes then increase continuously. The surface’s ultrasound-induced deflection is recorded with zero contact using laser vibrometers. Calculating Young’s modulus and Poisson’s ratio – the elastic variables – also allows for a more extensive assessment of the materials inspected.

Related products

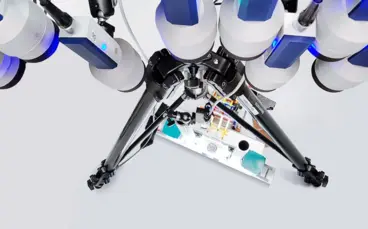

VibroScan QTec Xtra

VibroScan QTec Xtra measures vibrations in a new way - without contact, full-field and with unprecedented precision. With its groundbreaking multi-path interferometry, QTec® sets new standards in terms of optical sensitivity and interference immunity. The Xtra, based on an infrared (SWIR) laser is characterized by the highest optical sensitivity to guarantee highly accurate measurements even on demanding technical surfaces. VibroScan QTec Xtra ensures maximum portability through integrated data acquisition and signal generator up to 32 MHz.

VibroFlex

With the modular laser vibrometer VibroFlex, Polytec presents the superior flexibility in optical vibration measurement with a modular sensor solution up to 24 MHz that adapts to your needs: Add microscope objectives for observing tiny structures or measure large samples like machinery or motors from a safe distance. Discover acoustics and vibration phenomena in research and product development for a faster time-to-market or use it for reliable in-line inspections. Learn about how the patented multi-path interferometry QTec® provides an always stable signal level, 20 dB better SNR for faster and clearer results without post-processing.

Talk to our experts

Our experts are ready to support your projects with tailored measurement solutions or support you in measuring what matters—get in touch with us today.